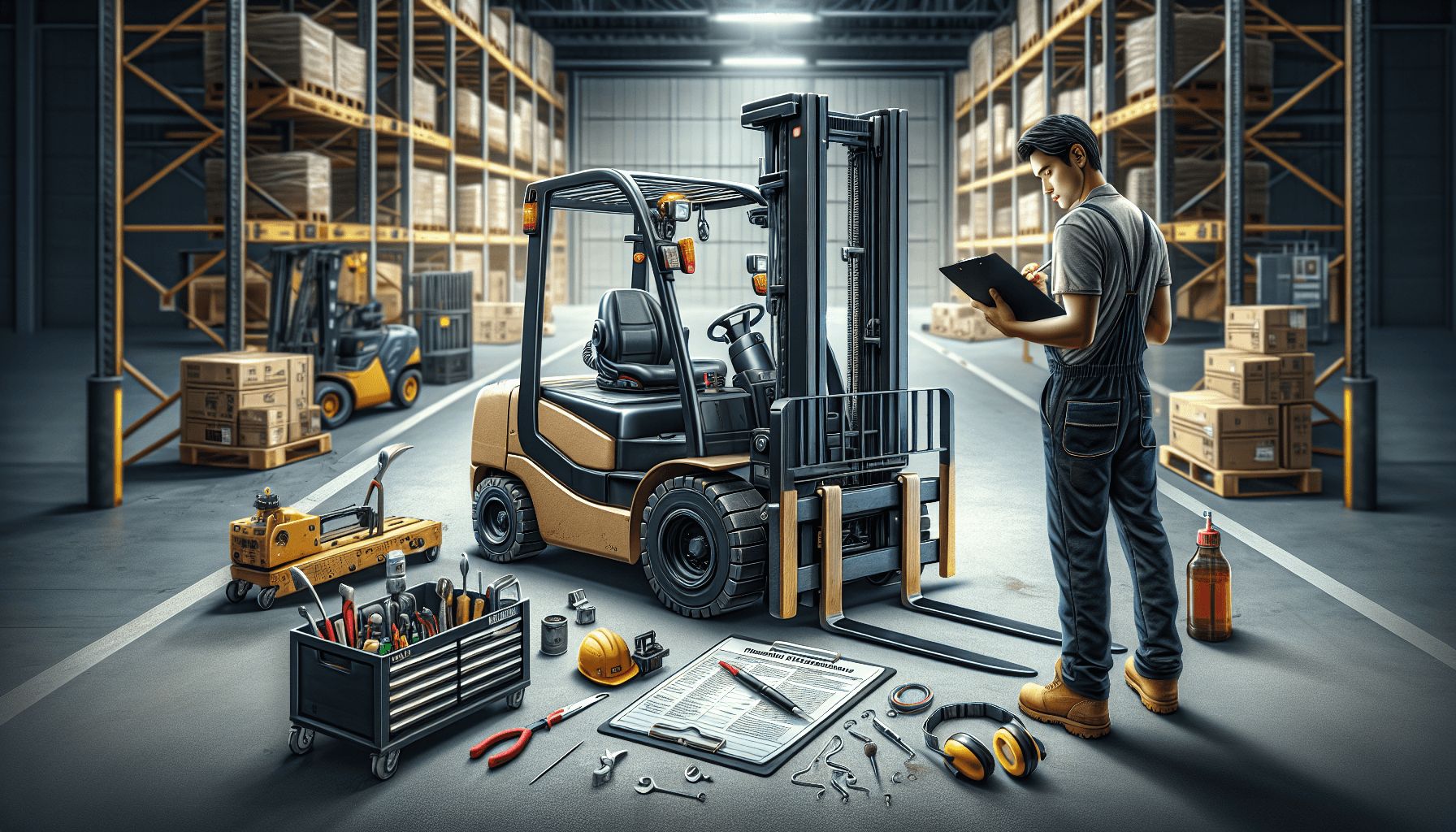

As a responsible business owner, you understand the importance of maintaining your equipment. This is especially true when it comes to forklifts, which are vital for many businesses in various industries. Developing a preventive maintenance plan for your forklifts is essential to ensure their optimal performance, reduce downtime, and extend their lifespan.

The Benefits of a Preventive Maintenance Plan

Before diving into the steps of developing a preventive maintenance plan for your forklifts, let’s take a moment to understand the benefits of implementing such a plan.

1. Increased Reliability: Regular maintenance helps identify and address potential issues before they become major problems. This reduces the chances of breakdowns and unexpected downtime, keeping your forklifts in reliable working condition.

2. Enhanced Safety: Well-maintained forklifts significantly reduce the risk of accidents and injuries in the workplace. Regular inspections and maintenance ensure that all safety features are functioning correctly, decreasing the likelihood of incidents.

3. Extended Lifespan: Forklifts are a significant investment, and regular maintenance helps prolong their lifespan. By addressing minor issues early on and properly caring for your forklifts, you can ensure they stay operational for a longer time, saving you money in the long run.

4. Cost Savings: Preventive maintenance is less expensive than emergency repairs or replacing a forklift prematurely. By following a maintenance plan, you can identify and fix minor issues at a lower cost, preventing them from escalating into more significant and costly problems.

Steps to Develop a Preventive Maintenance Plan for Your Forklifts

Now that we understand the advantages of having a preventive maintenance plan in place, let’s explore the steps to develop one for your forklifts:

1. Create a Maintenance Schedule: Start by creating a regular maintenance schedule for each forklift in your fleet. Consider factors like usage, manufacturer recommendations, and industry standards. This schedule will serve as a guideline for all maintenance activities.

2. Identify Critical Components: Determine the key components and systems that require regular inspection and upkeep. This will typically include the engine, hydraulic system, brakes, tires, and electrical components. Identify any specific maintenance tasks unique to your forklift model.

3. Establish Inspection Procedures: Develop detailed inspection procedures for your maintenance team to follow. These procedures should outline the specific checks to be performed, the frequency of inspections, and any documentation requirements. Inspections should encompass all aspects of the forklift’s operation and safety features.

4. Document Maintenance Activities: Maintain a comprehensive record of all maintenance activities conducted on each forklift. This documentation should include the date of maintenance, tasks performed, parts replaced, and any issues identified. Documentation helps track the maintenance history and serves as a reference for future inspections.

5. Train Maintenance Personnel: Ensure that your maintenance team receives adequate training on forklift maintenance procedures. This will enable them to effectively carry out inspections and repairs according to industry best practices. Encourage continuous learning and staying updated on the latest maintenance techniques.

6. Partner with Professionals: Consider partnering with a professional forklift fleet management company, such as HCO Innovations, to assist with your preventive maintenance needs. These experts have extensive knowledge and experience in maintaining forklifts and can provide additional support and guidance.

7. Regularly Review and Improve: Continuously evaluate your preventive maintenance plan and make necessary adjustments based on feedback from your maintenance team and forklift operators. Regular reviews and improvements will ensure that your plan remains effective and aligned with the changing needs of your business.

Implementing a comprehensive preventive maintenance plan for your forklifts requires commitment, organization, and attention to detail. However, the benefits far outweigh the investment of time and resources. A well-maintained forklift fleet will contribute to smoother operations, increased safety, and cost savings for your business.

Remember, partnering with a professional forklift fleet management company can provide your business with invaluable support in developing and implementing an effective preventive maintenance plan, ensuring the longevity and performance of your forklift fleet.