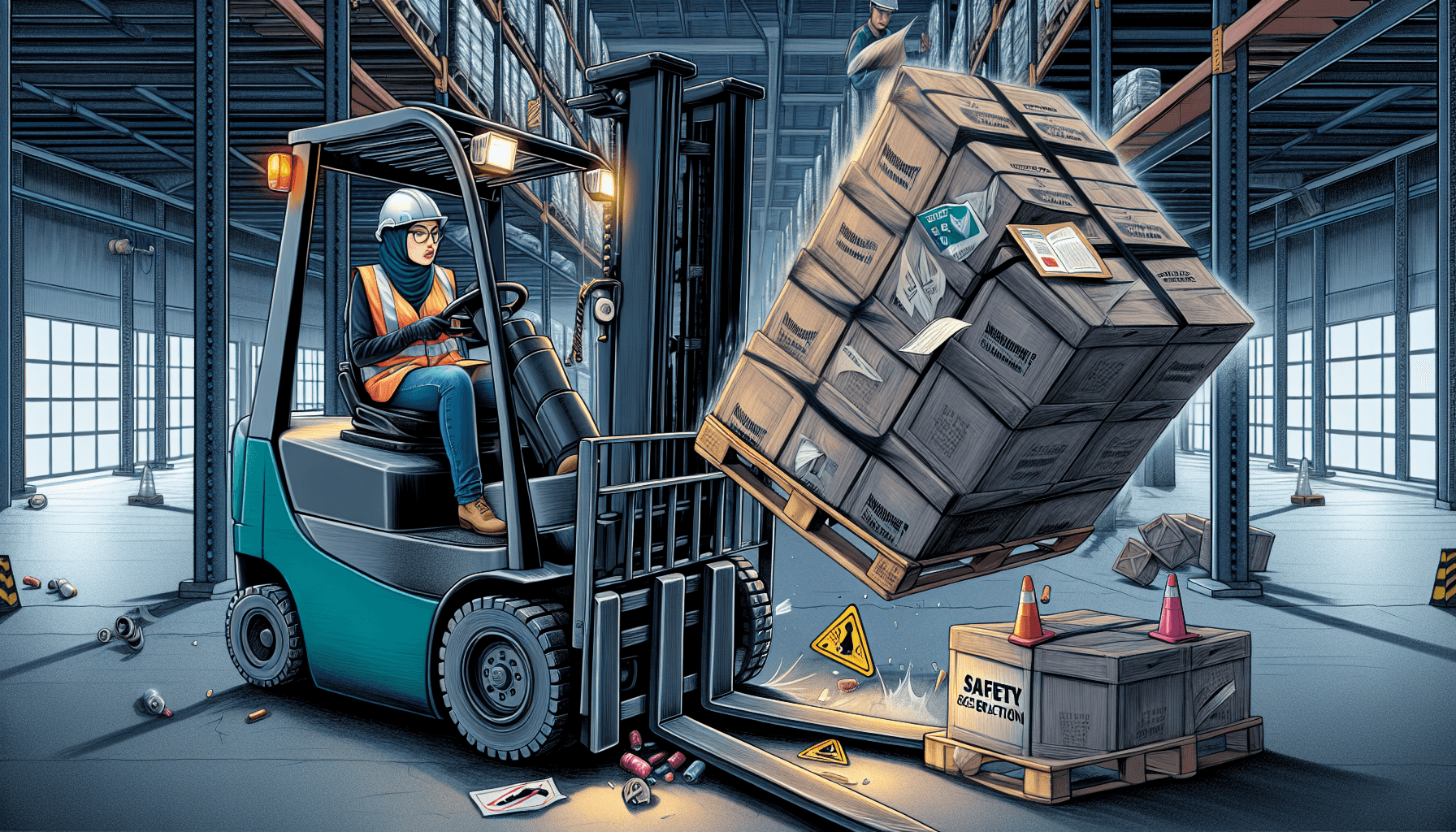

Have you ever had a near miss in your warehouse? Near misses are incidents that almost result in an injury or damage to property. Although they may not always result in harm, near misses serve as crucial opportunities to identify potential hazards and improve safety in your warehouse operations.

The Importance of Addressing Near Misses

Near misses should never be taken lightly. They are warning signs that something went wrong and could potentially lead to a serious accident if left unaddressed. By recognizing and investigating near misses, warehouse managers can take proactive steps to prevent future incidents and create a safer work environment for employees.

Here are some key reasons why addressing near misses is essential:

- Preventing future accidents: Near misses often indicate weaknesses or gaps in safety protocols. By addressing these issues, you can implement corrective measures to prevent similar incidents from happening in the future.

- Creating a safety culture: Taking near misses seriously demonstrates your commitment to employee safety. It helps foster a safety-oriented culture where employees are encouraged to report potential hazards without fear of reprisal.

- Reducing costs: Near misses may seem insignificant, but they can have significant financial implications if ignored. By addressing these incidents promptly, you can reduce the risk of future accidents, injuries, and associated costs such as medical expenses and worker’s compensation claims.

- Improving productivity: When employees feel safe at work, they are more likely to be motivated and productive. Addressing near misses and implementing safety measures helps create an environment where employees can focus on their tasks without worrying about potential hazards.

Steps to Handle Near Misses

Now that we understand the importance of addressing near misses, let’s take a look at the steps you can take to handle them effectively:

- Encourage reporting: Establish a system that encourages employees to report near misses without fear of punishment or blame. Encourage open communication and assure employees that their input is valued.

- Investigate thoroughly: When a near miss is reported, conduct a thorough investigation to identify the root cause and contributing factors. Interview involved parties, review surveillance footage if available, and gather any relevant information to gain a comprehensive understanding of the incident.

- Analyze and identify trends: Look for patterns or trends in near misses to identify common hazards or areas for improvement. This analysis will help you prioritize safety measures and allocate resources effectively.

- Implement corrective actions: Based on the investigation findings, develop and implement appropriate corrective actions. This may involve updating safety procedures, providing additional training, or modifying equipment to mitigate potential hazards.

- Educate and train employees: Regularly educate and train employees on safety protocols and procedures. Reinforce the importance of reporting near misses and empower employees to take an active role in identifying and addressing potential hazards.

- Monitor and evaluate: Continuously monitor the effectiveness of your corrective actions and safety measures. Regularly evaluate incident reports, conduct inspections, and involve employees in safety committees to ensure ongoing improvement.

Utilize HCO Innovations’ Warehouse Safety Evaluation

Implementing the steps mentioned above can significantly improve safety in your warehouse. However, if you need expert guidance and support, HCO Innovations is here to help. As a leading provider of warehouse optimization solutions, HCO Innovations offers a comprehensive Warehouse Safety Evaluation to assess and enhance safety measures in your warehouse.

The Warehouse Safety Evaluation by HCO Innovations includes:

- Thorough assessment of your current safety protocols

- Identification of potential hazards and areas for improvement

- Customized recommendations to enhance safety measures

- Training programs to educate employees on safety best practices

With HCO Innovations’ Warehouse Safety Evaluation, you can ensure that your warehouse operations are optimized for safety, productivity, and efficiency. Don’t wait for a serious accident to happen; take proactive steps to improve safety in your warehouse today!

For more information about HCO Innovations’ Warehouse Safety Evaluation, visit their website.