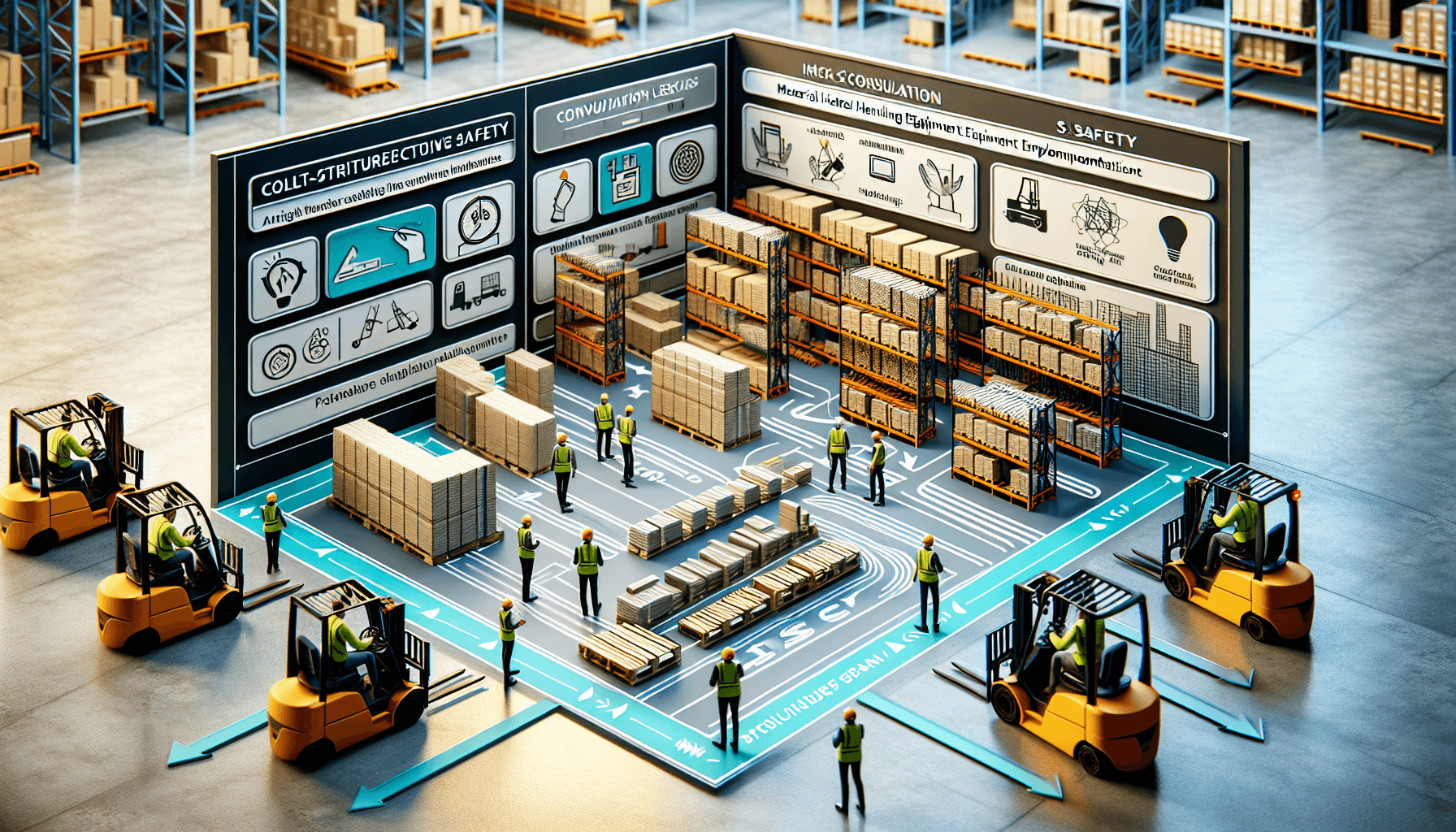

A well-implemented cost-efficient Material Handling Equipment (MHE) safety program is crucial for any warehouse operation. Not only does it ensure the safety of employees and equipment, but it also enhances productivity and efficiency. By following best practices and implementing effective measures, warehouses can significantly reduce accidents, injuries, and equipment downtime. In this article, we will discuss how to implement a cost-efficient MHE safety program that meets the unique needs of your warehouse.

Evaluate Your Current Safety Program

Before implementing any changes, it is essential to evaluate your current safety program. Review existing safety policies, procedures, and training materials to identify areas that need improvement. Conduct a thorough assessment of your warehouse layout, equipment, and workflows to identify potential hazards and risks.

Consider conducting a safety audit or hiring a professional safety consultant to provide a fresh perspective and help pinpoint areas for improvement. This step is crucial to ensure that your new safety program addresses the specific needs and challenges of your warehouse.

Develop a Comprehensive Training Program

A well-trained workforce is the foundation of a successful MHE safety program. Develop a comprehensive training program that educates employees on safe operating practices, equipment maintenance, and emergency procedures. Make sure that all employees, including operators, supervisors, and maintenance personnel, receive proper training.

Incorporate hands-on training sessions and simulations to ensure that employees understand how to operate equipment safely. Provide refresher courses regularly to reinforce good practices and keep up with any changes in equipment or procedures. Consider offering incentives for completing training and maintaining a safe work environment.

Additionally, make sure your training program includes information on hazard communication, personal protective equipment (PPE), and proper material handling techniques. Encourage employees to report any safety concerns or near-miss incidents so that appropriate actions can be taken to prevent accidents.

Implement Safety Measures and Guidelines

Implementing the right safety measures and guidelines is crucial to prevent accidents and injuries. Start by developing clear policies and procedures for operating MHE, such as forklifts, pallet jacks, and conveyors. Ensure that all employees are aware of and follow these guidelines at all times.

Consider implementing physical barriers, guardrails, and signage to delineate pedestrian walkways and separate them from equipment traffic areas. Clearly mark hazardous areas, such as loading docks, with highly visible signage and barriers to prevent unauthorized access and accidents.

In addition, ensure that your warehouse is equipped with the necessary safety equipment, such as fire extinguishers, first aid kits, and emergency exit signage. Regularly inspect and maintain safety equipment to ensure that it is accessible and in good working condition.

Regular equipment maintenance and inspections are also critical to ensuring safety and efficiency. Develop a preventive maintenance schedule and stick to it to identify and address any potential issues before they become hazardous. Encourage employees to report any equipment malfunctions or abnormalities promptly.

Promote a Culture of Safety

To ensure the long-term success of your MHE safety program, it is crucial to promote a culture of safety within your warehouse. This starts from the top down, with management setting a clear example and prioritizing safety in all aspects of operations.

Involve employees in safety initiatives by establishing a safety committee or team. Encourage them to participate in safety meetings, conduct regular safety inspections, and provide feedback or suggestions for improvement. Recognize and reward employees who consistently follow safety procedures and contribute to creating a safe work environment.

Regularly communicate and reinforce safety policies and procedures through training sessions, newsletters, or bulletin boards. Provide ongoing education and reminders to keep safety at the forefront of employees’ minds. Encourage open lines of communication, where employees feel comfortable reporting safety concerns or incidents without fear of retaliation.

Implementing a robust MHE safety program requires commitment, effort, and resources. However, the benefits far outweigh the costs. By prioritizing safety and implementing cost-effective measures, warehouses can minimize accidents, reduce downtime, increase productivity, and create a positive work environment for all employees.

Remember, safety should always be a top priority in warehouse operations. With a well-designed and implemented MHE safety program, you can ensure the smooth and efficient functioning of your warehouse while keeping your employees safe and your costs under control.