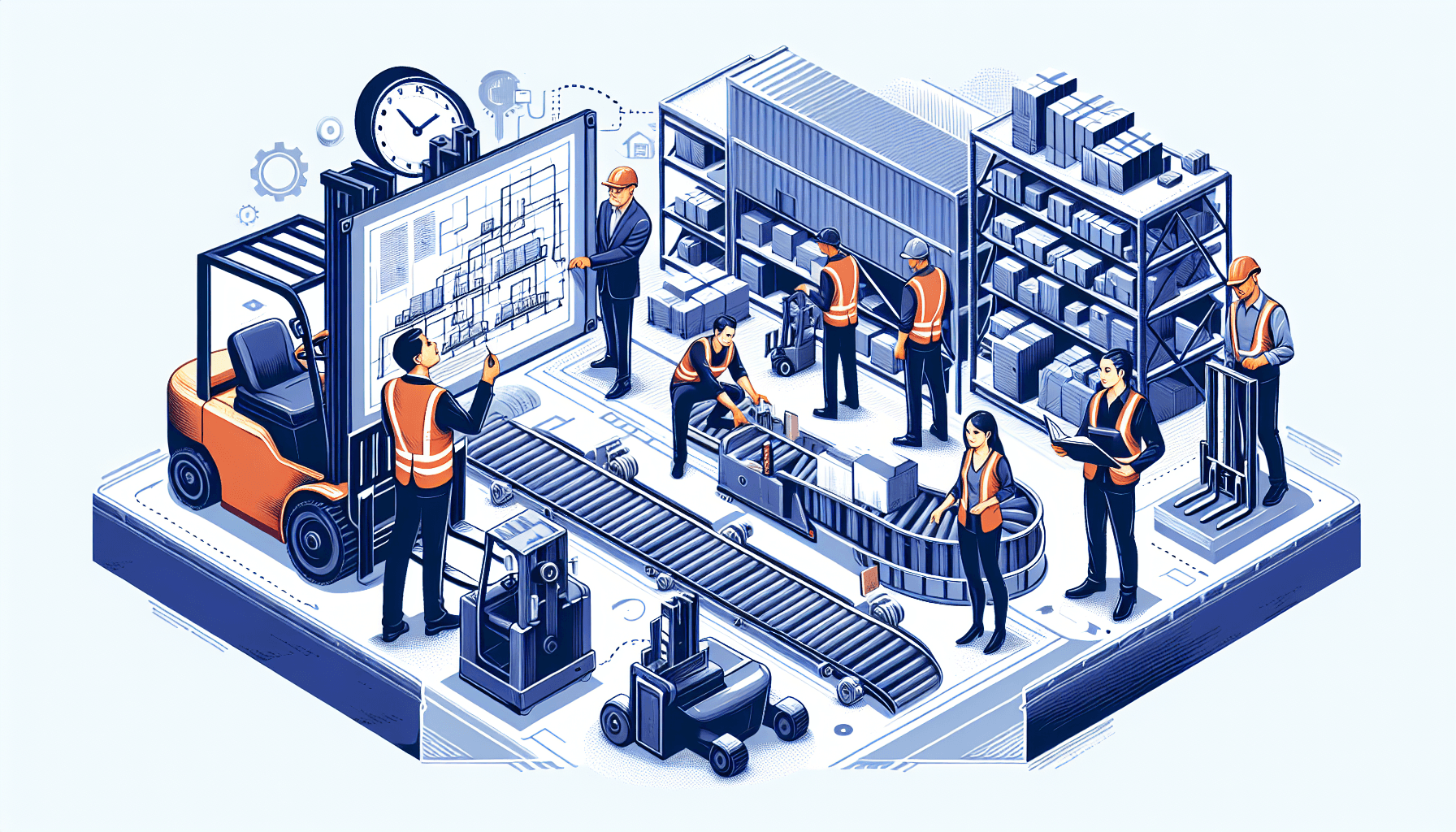

Are you struggling with outdated and inefficient material handling equipment (MHE) in your warehouse? Is it impacting your safety, productivity, and overall efficiency? It might be time to consider implementing an MHE replacement plan. Investing in new and advanced equipment can greatly improve your warehouse operations and ultimately lead to cost-effectiveness. In this article, we will discuss the steps involved in implementing an MHE replacement plan and how it can benefit your business.

Evaluate Current Equipment

The first step in implementing an MHE replacement plan is to evaluate your current equipment. Take a close look at each piece of MHE in your warehouse and assess its condition, performance, and usability. Identify any equipment that is outdated, inefficient, or in need of frequent repairs. This evaluation will help you determine which equipment needs to be replaced and provide you with valuable insights for selecting the right replacements.

Once you have identified the equipment that needs to be replaced, it’s important to set clear goals and objectives for your MHE replacement plan. Determine the key areas where you need improvement, such as safety, productivity, efficiency, or cost-effectiveness. These goals will guide your decision-making process and ensure that the new equipment aligns with your specific needs.

Research and Explore Options

With your goals and objectives in mind, it’s time to research and explore the available options. Look for reputable suppliers and manufacturers that specialize in warehouse optimization solutions. HCO Innovations is a prominent provider of such solutions. They have a wide range of material handling equipment management services that can help you optimize your warehouse operations and achieve your goals. Learn more here.

When exploring options, consider factors such as equipment durability, performance capabilities, ease of use, maintenance requirements, and scalability. The equipment you choose should be able to handle your current workload while also accommodating any future growth or changes in your operations. It’s also essential to evaluate the supplier’s reputation, customer support, and warranty options.

Create a Detailed Implementation Plan

Once you have selected the equipment and supplier that best fit your needs, it’s time to create a detailed implementation plan. This plan should outline the steps, timelines, and resources required to successfully replace the MHE in your warehouse.

Assign responsibilities to key team members who will oversee the implementation process. Ensure that they have a clear understanding of their roles and expectations. Develop a timeline that allows for smooth transition and minimal disruptions to your daily warehouse operations. Consider any space or infrastructure modifications that may be necessary to accommodate the new equipment.

Communication is key during the implementation phase. Keep your team informed about the progress and any changes that may affect their work. Provide training sessions for the operators to ensure they are comfortable and proficient in using the new equipment. Regularly evaluate the performance of the new MHE and make adjustments as needed.

Monitor and Optimize

Implementing an MHE replacement plan is not a one-time event. It is an ongoing process that requires monitoring and optimization. Continuously evaluate the performance of your new equipment and compare it with the set goals and objectives. Identify any areas that need improvement and take proactive measures to address them.

Regular maintenance and servicing of the MHE is crucial to keep it in optimal condition. Schedule routine inspections, and address any repairs or issues promptly. Provide ongoing training and support to your team to ensure they are maximizing the benefits of the new equipment.

Monitoring key performance indicators (KPIs) such as time savings, error rates, and productivity levels will help you assess the success of your MHE replacement plan. Make adjustments and refinements as necessary to ensure that your warehouse operations continue to improve over time.

In conclusion, implementing an MHE replacement plan can significantly enhance the safety, productivity, efficiency, and cost-effectiveness of your warehouse operations. By evaluating your current equipment, researching and exploring options, creating a detailed implementation plan, and monitoring and optimizing the new equipment, you can achieve your goals and take your warehouse operations to the next level.