Forklifts are an essential tool for warehouse operations, helping to streamline the movement and transportation of goods within a facility. They rely on batteries to power their operations, making efficient forklift battery management crucial for maximizing productivity and minimizing downtime. In this article, we will discuss some best practices for implementing forklift battery management strategies.

Regular Maintenance and Inspections

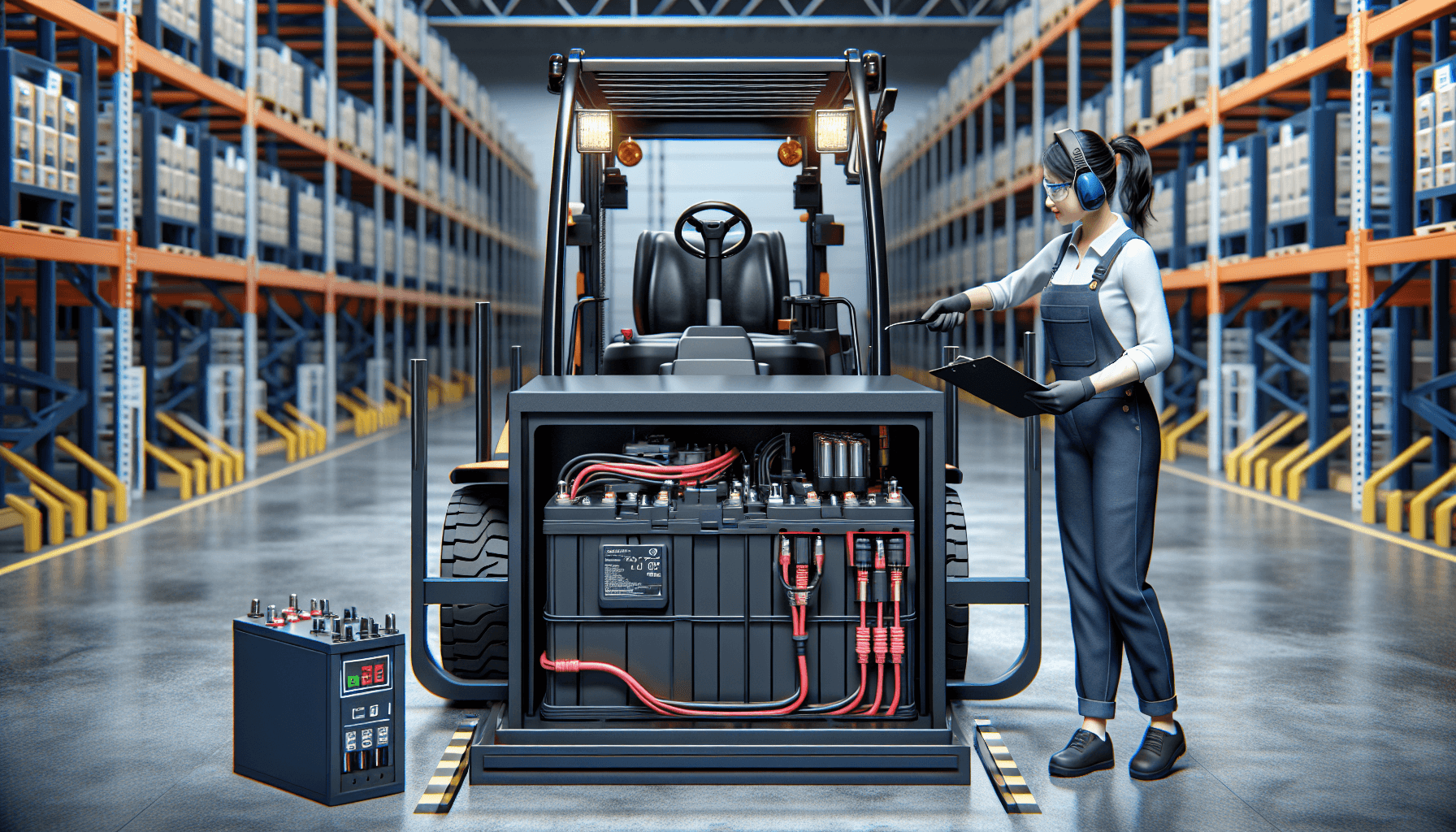

One of the key factors in ensuring optimal performance and longevity of forklift batteries is regular maintenance and inspections. Establishing a maintenance schedule and sticking to it is important in identifying and addressing any potential issues before they escalate. This includes checking for signs of wear, corrosion, or damage to the battery and its connections.

Additionally, conducting routine electrical tests and measurements can help identify any weaknesses or inefficiencies in the battery. This includes monitoring voltage levels, specific gravity, and water levels to ensure they fall within the recommended ranges. Regular maintenance and inspections are crucial for preventing unexpected battery failures and extending the lifespan of the battery.

Proper Charging and Discharging

Another important aspect of forklift battery management is implementing proper charging and discharging practices. Charging the batteries correctly not only ensures their longevity but also maximizes their performance and efficiency. It is essential to follow the manufacturer’s guidelines and recommendations for charging procedures and to use the correct charging equipment.

Overcharging or undercharging the batteries can have detrimental effects, leading to reduced battery life and decreased performance. It is important to properly monitor the charging process, avoid overcharging, and ensure that the charging cycles are completed. Implementing an automated battery management system can help monitor and control the charging process effectively.

Discharging the batteries correctly is equally important. Allowing the batteries to discharge too much before recharging can cause irreversible damage. Implementing a battery management system that monitors and controls the minimum voltage levels can help prevent over-discharge and extend the battery life.

Proper Battery Handling and Storage

Proper handling and storage of forklift batteries is crucial for the safety of employees and the longevity of the batteries themselves. When handling batteries, it is important to wear appropriate personal protective equipment (PPE) such as gloves and goggles to prevent any exposure to chemicals or acid leaks.

During storage, batteries should be kept in a clean, dry, and well-ventilated area. They should be stored in designated battery racks or on pallets, ensuring they are not in direct contact with the floor. Regularly inspecting the storage area for any signs of leaks or potential hazards is essential for maintaining a safe working environment.

Implementing a comprehensive forklift fleet power management solution can provide numerous benefits, such as optimizing charging processes, monitoring battery health, and efficient battery usage. These solutions use advanced technologies to improve the performance and longevity of forklift batteries, ultimately enhancing productivity and reducing costs.

Employee Training and Education

Lastly, providing proper training and education to forklift operators and maintenance personnel is essential for effective battery management. Employees should be trained on proper battery handling techniques, charging procedures, and recognizing signs of battery deterioration or malfunction.

Regularly conducting refresher training sessions and keeping employees up to date with the latest industry trends can help ensure consistent adherence to best practices. In addition, creating a culture of awareness and responsibility around forklift battery management can greatly contribute to the success of the overall strategy.

Implementing these forklift battery best practices can significantly enhance the safety, productivity, and efficiency of warehouse operations. By prioritizing regular maintenance, proper charging and discharging, adequate handling and storage, and ongoing training, businesses can maximize the performance and lifespan of their forklift batteries, ultimately leading to improved operational and cost-effectiveness.

Remember, HCO Innovations is your trusted partner in warehouse optimization solutions. Check out our website for more information on how we can help enhance your warehouse operations.

What are forklift battery best practices?

Forklift battery best practices refer to a set of guidelines and strategies that ensure optimal performance and longevity of forklift batteries. These practices include proper charging, maintenance, and handling techniques.

Why is it important to implement forklift battery best practices?

Implementing forklift battery best practices is important because it helps extend the lifespan of the batteries, increases productivity by reducing downtime for charging and maintenance, and improves overall safety in the workplace.

How often should forklift batteries be charged?

Forklift batteries should be charged after each shift or when the charge drops to 30% capacity. Regular charging helps prevent deep discharges, which can negatively impact the battery's performance and lifespan.

What is the recommended charging method for forklift batteries?

The recommended charging method for forklift batteries is the opportunity charging method. This involves charging the batteries during short, regular breaks throughout the operational hours, rather than waiting for them to fully discharge before charging. This helps maintain a high battery charge, reduces the risk of downtime, and extends battery life.

How should forklift batteries be maintained?

Forklift batteries should be properly maintained by ensuring they are kept clean, free from debris and corrosion, and regularly inspected for any signs of damage or wear. It is also important to follow the manufacturer's recommendations for adding water to the battery, checking and cleaning the battery terminals, and conducting routine maintenance tasks such as equalizing charges.

What are the safety precautions when handling forklift batteries?

When handling forklift batteries, it is important to wear proper personal protective equipment (PPE) such as gloves and goggles to protect against acid spills and splashes. Additionally, batteries should always be lifted and moved using the appropriate equipment and techniques to prevent injuries and accidents.

Can forklift batteries be recycled?

Yes, forklift batteries can and should be recycled. They contain hazardous materials such as lead and acid, which can be harmful if not disposed of properly. Recycling helps reduce environmental impact and ensures that valuable materials are reused.

What are the signs that a forklift battery needs replacing?

Signs that a forklift battery may need replacing include reduced runtime, decreased performance, difficulty holding a charge, excessive heat or swelling, and visible physical damage such as leaks or cracks. If any of these signs are observed, it is advisable to consult with a professional for further evaluation and potential battery replacement.

Maintaining a Sustainable Warehouse: Eco-Friendly Practices to Reduce Environmental Impact

In today's world, sustainability is no longer just a buzzword, but a crucial aspect of every industry. As businesses strive to reduce their environmental impact, warehouse management is an area that cannot be overlooked. Warehouse operations have a significant carbon footprint, from energy usage to material wastage. At HCO Innovations, we understand the importance of maintaining a sustainable warehouse and have developed eco-friendly practices to help reduce the environmental impact of warehouse operations.

The Importance of Sustainable Warehousing

A sustainable warehouse goes beyond just complying with environmental regulations. It aims to minimize its carbon footprint, conserve resources, and adopt practices that promote environmental stewardship. Adopting sustainable warehousing practices offers numerous benefits, including:

- Cost Savings: By implementing energy-efficient measures and reducing waste, businesses can lower their operating costs in the long run.

- Brand Reputation: Embracing sustainability can enhance a company's brand image and attract environmentally conscious customers.

- Regulatory Compliance: Adhering to environmental regulations ensures that businesses avoid penalties and legal issues.

- Employee Morale: Employees are more likely to be engaged and satisfied working for an environmentally responsible company.

- Future-Proofing: By adopting sustainable practices now, businesses are better prepared for future regulatory changes and customer demands.

Eco-Friendly Practices for Warehouse Sustainability

Implementing eco-friendly practices in warehouse operations requires a holistic approach. Here are some key practices to consider:

1. Energy Efficiency

Reducing energy consumption is one of the most effective ways to make a warehouse more sustainable. Here are a few energy-saving measures:

- Invest in energy-efficient lighting systems such as LED lights. These lights consume less energy and have a longer lifespan. They also provide better illumination, improving visibility and safety.

- Install motion sensors to automatically turn off lights in areas that are not in use.

- Use natural lighting whenever possible by incorporating skylights or large windows in the warehouse design.

- Optimize HVAC systems to ensure efficient heating and cooling. Proper insulation and regular maintenance of equipment are crucial.

- Consider installing renewable energy sources such as solar panels to generate clean, renewable power for the warehouse.

2. Waste Reduction and Recycling

Warehouse operations generate a significant amount of waste, including packaging materials, pallets, and excess inventory. Implementing waste reduction and recycling initiatives can greatly reduce the environmental impact. Here's how:

- Implement a comprehensive recycling program that includes recycling bins strategically placed throughout the warehouse for easy access. Clearly label bins and provide training to employees on proper recycling practices.

- Reuse and repurpose packaging materials whenever possible to minimize waste. Collaborate with suppliers and customers to ensure sustainable packaging practices are followed throughout the supply chain.

- Optimize inventory management systems to minimize excess inventory and reduce the risk of product obsolescence.

- Partner with recycling companies to dispose of hazardous materials responsibly.

3. Optimized Warehouse Layout

The layout of a warehouse plays a crucial role in maximizing operational efficiency and reducing environmental impact. Consider the following strategies:

- Optimize the storage layout to minimize travel distance and improve material flow. This reduces energy consumption and increases productivity.

- Implement a well-designed slotting system that ensures fast-moving items are easily accessible, reducing the need for unnecessary movement and minimizing energy usage.

- Utilize vertical space effectively by implementing mezzanine storage systems. This allows for additional storage without expanding the warehouse's physical footprint.

4. Transportation and Logistics

Transportation and logistics are key areas where sustainable practices can have a significant impact. Consider the following:

- Collaborate with transportation service providers to optimize delivery routes, reducing fuel consumption and carbon emissions.

- Utilize electric or hybrid vehicles for transportation within the warehouse premises, reducing air pollution.

- Implement a reverse logistics system to facilitate the return and recycling of products, reducing waste and promoting circular economy practices.

- Promote telecommuting or carpooling among employees to reduce commute-related carbon emissions.

Conclusion

Adopting sustainable practices in warehouse operations is not only beneficial for the environment but also for business operations. HCO Innovations is committed to helping businesses achieve their sustainability goals through our expertise in warehouse optimization and forklift fleet management. By incorporating energy-efficient measures, waste reduction strategies, optimized layout, and sustainable transportation practices, businesses can significantly reduce their environmental impact and create a more sustainable future.

If you're interested in optimizing your warehouse operations and reducing your environmental impact, contact us to learn more about how HCO Innovations can help.