In the fast-paced world of warehouse operations, efficiency is key. The ability to maximize productivity while minimizing costs is what sets successful companies apart from the competition. One area that often gets overlooked when it comes to cost savings is forklift power usage. By implementing forklift power upgrades, businesses can not only improve efficiency and safety but also realize significant cost savings. In this article, we will explore the benefits of forklift power upgrades and provide some valuable tips on how to implement them effectively.

Why Forklift Power Upgrades Matter

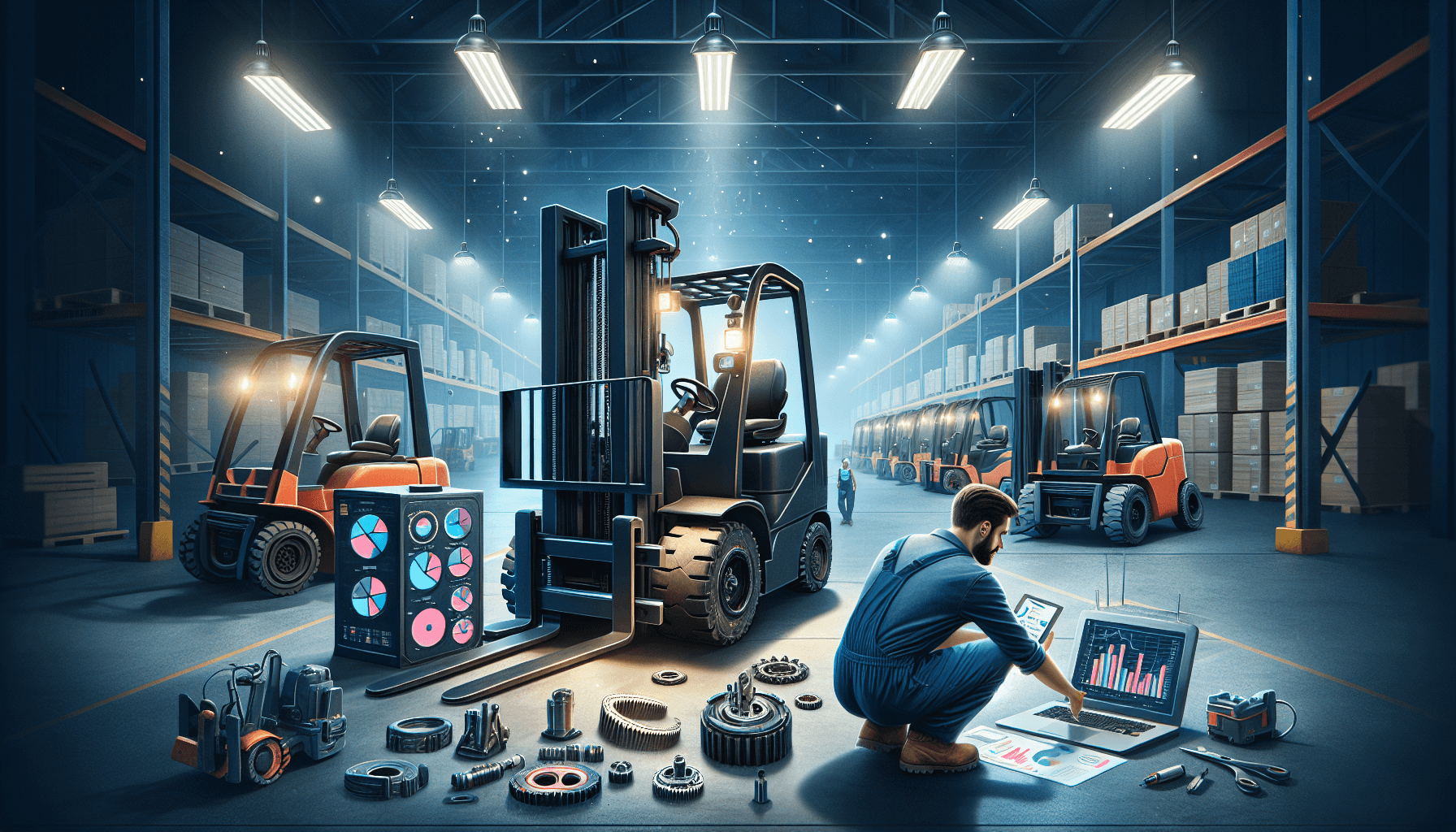

Forklifts are the workhorses of any warehouse, performing critical tasks such as loading, unloading, and transporting goods. However, outdated or inefficient forklift power systems can hinder productivity and increase operational costs. By upgrading the power systems of your forklift fleet, you can mitigate these challenges and achieve substantial benefits.

One of the primary advantages of forklift power upgrades is improved efficiency. Modern power systems, such as lithium-ion batteries, offer longer run times and faster recharging capabilities. With longer battery life, forklift operators can work longer shifts without interruptions for recharging or battery changes. This translates to increased productivity and reduced downtime, leading to enhanced operational efficiency.

Furthermore, forklift power upgrades can help reduce maintenance costs. Traditional lead-acid batteries require regular maintenance, including watering, equalizing charging, and cleaning. On the other hand, advanced power systems like lithium-ion batteries require minimal maintenance, freeing up valuable time and resources for other critical tasks in the warehouse.

Safety is always a top priority in warehouse environments. Forklift power upgrades can contribute to a safer working environment by reducing the risk of accidents and equipment malfunctions. Modern power systems are designed with enhanced safety features, such as thermal management systems and built-in safety mechanisms, to prevent overheating and other potential hazards.

Implementing Forklift Power Upgrades

Now that we understand the importance of forklift power upgrades, let’s discuss how to implement them effectively in your warehouse operations. Below are some essential steps to consider:

- Assess your current forklift fleet: Begin by conducting a thorough assessment of your existing forklift fleet. Identify the forklifts that are candidates for power upgrades based on their age, usage patterns, and performance. This evaluation will help you prioritize which forklifts should receive power upgrades first.

- Research power upgrade options: Once you have identified the forklifts in need of upgrades, research the available power upgrade options. Consider factors such as battery technology, charging infrastructure requirements, and compatibility with your existing forklift fleet. Consulting with a reputable warehouse optimization solutions provider like HCO Innovations can help you navigate through the available options and make informed decisions.

- Plan your budget: Implementing forklift power upgrades involves some initial investment. Therefore, it is essential to plan your budget accordingly. Consider the long-term benefits and potential cost savings when budgeting for power upgrades. Consult with your finance department to determine the feasible budget allocation for this project.

- Train your staff: Upgrading the power systems of your forklift fleet may require some training for your staff. Ensure that your forklift operators and maintenance personnel receive adequate training on the new power systems. This will help them understand the proper operation, maintenance, and safety protocols associated with the upgraded power systems.

- Monitor and measure the impact: Once the power upgrades are implemented, continuously monitor and measure their impact on your warehouse operations. Keep track of metrics such as productivity, energy consumption, and maintenance costs. This data will help you evaluate the effectiveness of the upgrades and make any necessary adjustments or optimizations.

In conclusion, forklift power upgrades can have a significant impact on warehouse operations, leading to improved efficiency, cost savings, and enhanced safety. By assessing your current fleet, researching power upgrade options, planning your budget, training your staff, and monitoring the impact, you can successfully implement forklift power upgrades in your operations. Remember, partnering with a trusted provider like HCO Innovations can provide invaluable expertise and guidance throughout the process. Take the first step towards optimizing your warehouse operations and consider implementing forklift power upgrades today!

For more information on forklift fleet power management and how HCO Innovations can assist you in optimizing your warehouse operations, visit this link.