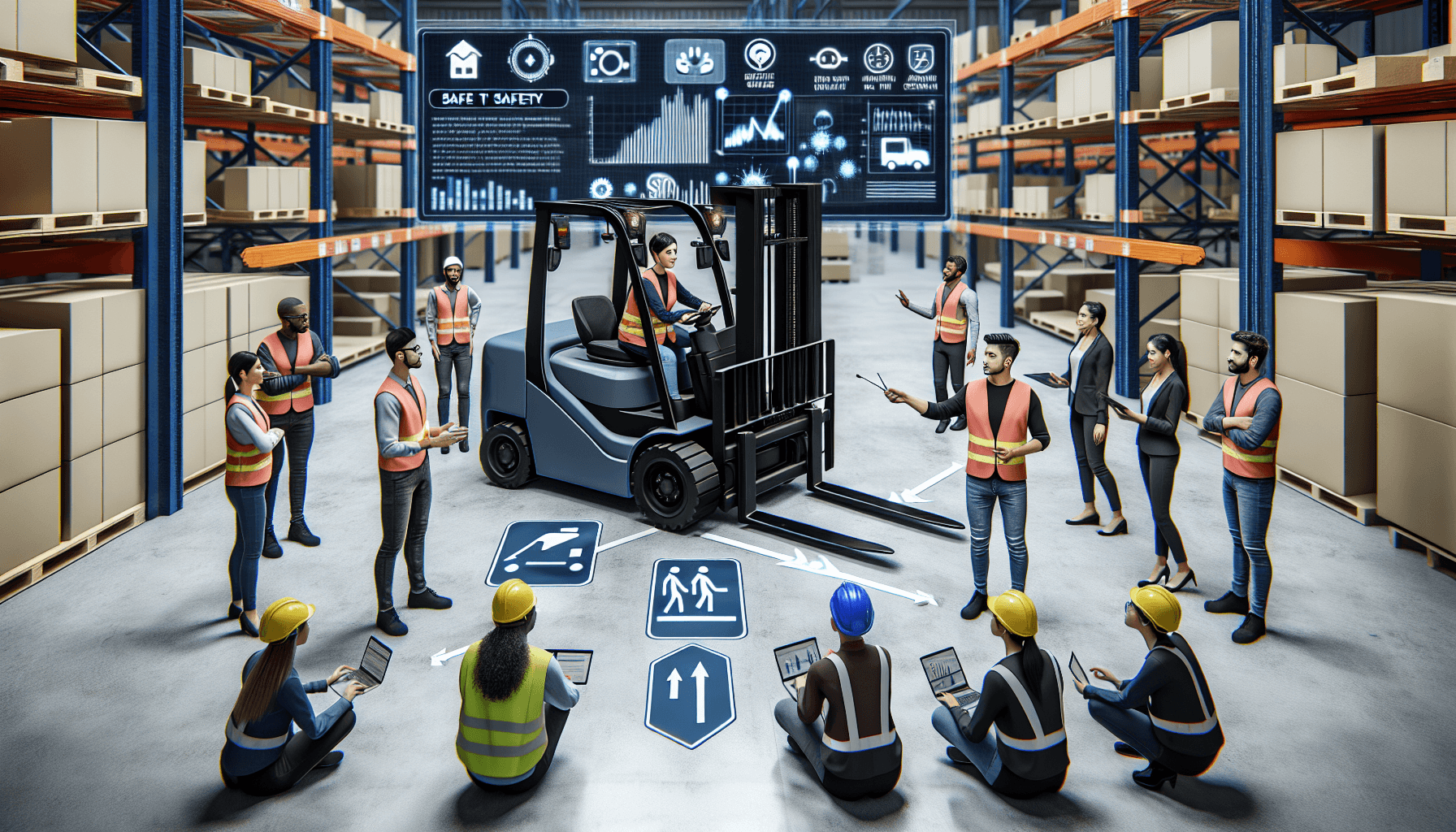

Implementing forklift safety measures in agile work environments is crucial to ensure the well-being of workers and the efficient operation of warehouse tasks. Forklifts are powerful machines used to lift and transport heavy loads, but they can also pose significant risks if not used properly. In this article, we will explore the essential steps you can take to implement forklift safety in agile work environments.

1. Provide Proper Training

The first and most critical step in implementing forklift safety is to provide comprehensive training for all operators. Forklift operators should receive training on safe operation, load handling, maneuvering, and parking. They should also be familiar with the warehouse layout, including any potential hazards such as ramps, narrow aisles, or blind spots.

It is recommended to hire a professional forklift training company to conduct the training sessions. They can provide hands-on demonstrations and practical exercises to ensure that operators are well-prepared to handle the forklifts safely. Regular refresher courses should also be conducted to reinforce the importance of safety protocols.

2. Establish Clear Traffic Management Procedures

In an agile work environment, where multiple tasks are happening simultaneously, it is essential to establish clear traffic management procedures to avoid collisions and accidents. This includes setting designated forklift lanes, pedestrian walkways, and enforcing speed limits.

Signage and markings should be used to clearly indicate these designated areas and promote awareness among workers. It is also crucial to educate all employees about the traffic management procedures and the importance of following them consistently.

3. Regularly Maintain and Inspect Forklifts

Maintaining and inspecting forklifts regularly is vital to ensure their safe operation. A scheduled maintenance program should be in place to address any potential issues or malfunctions promptly.

Operators should perform pre-shift inspections to check for any visible damage, fluid leaks, worn-out tires, or malfunctioning controls. Any identified issues should be reported and addressed immediately by a qualified technician before using the forklift.

4. Provide Personal Protective Equipment (PPE)

Personal protective equipment (PPE) plays a crucial role in forklift safety. All forklift operators and warehouse workers should be provided with the necessary PPE, including high-visibility vests, safety helmets, and steel-toe boots.

Properly fitting PPE should be worn at all times while operating or working around forklifts. Regular checks should be conducted to ensure compliance with PPE requirements and to replace any damaged or worn-out equipment.

5. Implement Safety Audits

Regular safety audits are crucial to identify any potential safety hazards and make necessary improvements. Safety audits should be conducted by trained professionals who can assess the overall safety performance of the warehouse, including forklift operations.

HCO Innovations offers a comprehensive warehouse safety evaluation service that can help identify safety gaps, provide recommendations, and assist in implementing best practices. Conducting safety audits periodically will ensure ongoing compliance with safety standards and continuous improvement in forklift safety.

Conclusion

Implementing forklift safety in agile work environments is crucial for the well-being of workers and the smooth operation of warehouse tasks. By providing proper training, establishing clear traffic management procedures, regularly maintaining and inspecting forklifts, providing personal protective equipment, and implementing safety audits, you can create a safe and productive work environment.

Remember, forklift safety is a shared responsibility, and everyone in the warehouse should be educated and aware of the protocols to ensure a safe working environment.

Why is forklift safety important in agile work environments?

Forklift safety is crucial in agile work environments to prevent accidents, injuries, and damage to property. Forklifts are powerful machines that require proper training and adherence to safety protocols to ensure the well-being of workers and the efficient operation of the workplace.

What are some common forklift safety hazards in agile work environments?

Some common forklift safety hazards in agile work environments include collisions with pedestrians or other vehicles, tip-overs caused by improperly balanced loads or high speeds, inadequate visibility in crowded or poorly lit areas, and improper use of forklift attachments.

How can forklift operators promote safety in agile work environments?

Forklift operators can promote safety in agile work environments by undergoing thorough training and certification programs, following safe operating procedures and guidelines, conducting pre-operational inspections of forklifts, maintaining clear communication with other workers, and staying aware of their surroundings at all times.

What is the role of management in ensuring forklift safety in agile work environments?

Management plays a critical role in ensuring forklift safety in agile work environments. They should provide proper training and certification opportunities for operators, enforce safety policies and procedures, conduct regular inspections of forklifts and workplace conditions, provide adequate maintenance and repair resources, and encourage a culture of safety throughout the organization.

Are there any specific regulations or standards for forklift safety in agile work environments?

Yes, there are specific regulations and standards for forklift safety in agile work environments. In the United States, the Occupational Safety and Health Administration (OSHA) has established the Powered Industrial Truck standard (29 CFR 1910.178) that outlines requirements for training, operation, and maintenance of forklifts. It is essential for organizations to familiarize themselves with these regulations and ensure compliance.

How can I minimize the risk of accidents when using a forklift in an agile work environment?

You can minimize the risk of accidents when using a forklift in an agile work environment by implementing safety measures such as enforcing speed limits, ensuring proper training and certification of operators, maintaining clear visibility through proper lighting and mirrors, organizing and maintaining a clutter-free workplace, using proper lifting techniques, and regularly inspecting and maintaining forklifts and equipment.

What should I do in case of a forklift accident in the workplace?

If a forklift accident occurs in the workplace, it is crucial to prioritize the safety of individuals involved. Immediately provide medical assistance if needed and report the incident to management. It is important to investigate the accident, identify the root causes, and implement corrective actions to prevent similar incidents in the future.

What should I do if I notice a safety hazard related to forklift operations in an agile work environment?

If you notice a safety hazard related to forklift operations in an agile work environment, report it to your supervisor or the responsible person in your organization. Communicating safety concerns is essential to mitigate potential risks and ensure a safer work environment for everyone.

Implementing Effective Ergonomics in Agile Work Environments

In today's fast-paced and ever-evolving work environments, businesses are constantly searching for ways to increase efficiency and productivity. One area that plays a crucial role in achieving these goals is the implementation of effective ergonomics in agile work environments. By prioritizing the well-being of employees and optimizing their workstations, companies can create a healthier and more productive work environment.

The Importance of Ergonomics in Agile Work Environments

Ergonomics is the science of designing and arranging workspaces and tools to fit the capabilities and limitations of individuals. It focuses on optimizing the interaction between workers and their environment to reduce the risk of injuries and increase efficiency. In agile work environments, where employees are constantly adapting and collaborating, the importance of ergonomics becomes even more critical.

Agile work environments are characterized by their flexibility and dynamic nature. Employees often switch between tasks and workstations, requiring them to quickly adapt to new settings. Without proper ergonomic design, employees may experience discomfort, fatigue, and even injuries, leading to decreased productivity and increased absenteeism.

By implementing effective ergonomics in agile work environments, businesses can:

- Reduce the risk of musculoskeletal disorders (MSDs): Agile work environments often involve repetitive tasks and prolonged periods of sitting or standing. By providing ergonomic workstations and encouraging proper posture and movement, companies can significantly reduce the risk of MSDs such as back pain, repetitive strain injuries, and carpal tunnel syndrome.

- Enhance productivity: Comfortable and well-designed workstations can improve employee focus and concentration, leading to increased productivity. Ergonomic furniture, adjustable desks, and supportive chairs can help employees maintain a healthy posture and reduce fatigue, allowing them to work efficiently for longer periods.

- Promote employee well-being and satisfaction: When employees feel supported and comfortable in their work environment, it has a positive impact on their overall well-being and satisfaction. This, in turn, leads to higher employee engagement, reduced turnover rates, and improved morale.

When it comes to implementing effective ergonomics in agile work environments, businesses can turn to HCO Innovations for expert guidance and solutions. HCO Innovations is a leading management consulting firm specializing in warehouse optimization and forklift fleet management. With extensive experience in optimizing work environments, HCO Innovations offers comprehensive services to ensure businesses achieve maximum ergonomic efficiency.

HCO Innovations takes a collaborative "boots on the ground" approach to assess and evaluate workstations. Their team of experts analyzes the unique needs of each employee and identifies areas for improvement. Using advanced cost-tracking software, they provide customized solutions that address ergonomic challenges and enhance productivity.

When working with HCO Innovations, businesses can expect:

- A comprehensive evaluation of workstations: HCO Innovations conducts an in-depth evaluation of workstations, taking into account factors such as desk height, seating arrangement, monitor placement, and ergonomic accessories.

- Customized ergonomic solutions: Based on the evaluation findings, HCO Innovations designs customized solutions to optimize workstations. This may include ergonomic furniture, adjustable desks, monitor arms, keyboard trays, and other accessories.

- Training and education: HCO Innovations provides training and education to employees, ensuring they understand the importance of ergonomics and how to maintain proper posture and movement throughout the day.

- Ongoing support and maintenance: HCO Innovations offers ongoing support and maintenance to ensure that ergonomic solutions continue to meet the evolving needs of employees.

By partnering with HCO Innovations, businesses can achieve significant cost reductions and operational efficiency by optimizing their work environments. The tailored ergonomic solutions provided by HCO Innovations consistently deliver exceptional returns on investment, making them a trusted partner for businesses across industries.

Implementing effective ergonomics in agile work environments is essential for promoting employee well-being, reducing the risk of injuries, and maximizing productivity. By partnering with HCO Innovations, businesses can ensure that their workspaces are optimized for the health and comfort of their employees. To learn more about HCO Innovations' consulting services and how they can help your business, visit their website here.