Inventory management is a crucial aspect of any business, especially for companies with warehouse operations. Having an efficient and streamlined inventory management system can greatly impact a company’s success. One effective tool that can greatly improve inventory management is a Warehouse Management System (WMS). In this article, we will explore the benefits of implementing a WMS for better inventory management and how HCO Innovations can help businesses achieve optimal warehouse optimization through their innovative solutions.

The Benefits of Implementing a WMS

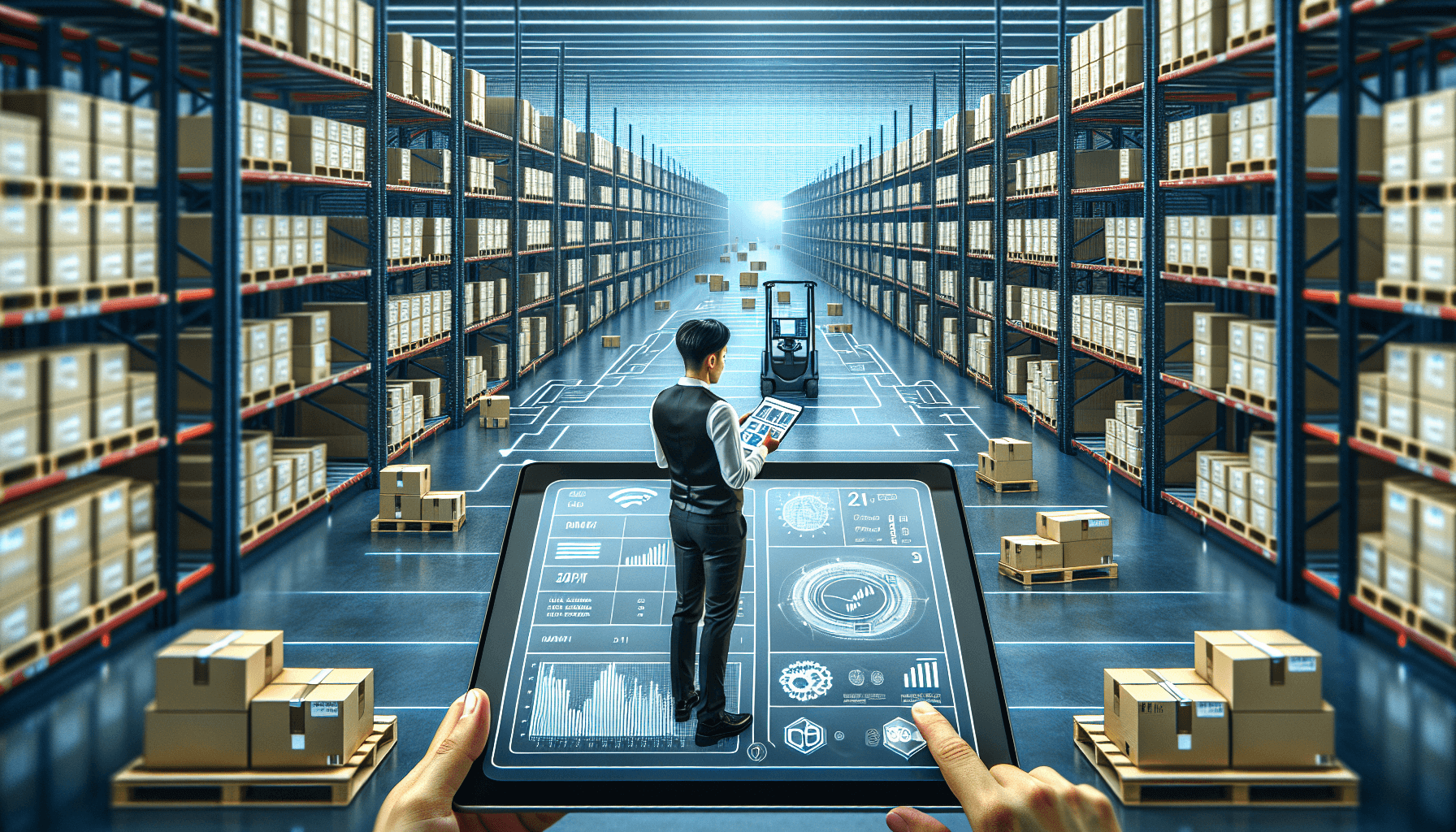

A Warehouse Management System (WMS) is a software application that helps businesses efficiently manage and control their warehouse operations. By implementing a WMS, businesses can experience a wide range of benefits that positively impact their inventory management. Let’s delve into some of the key advantages of implementing a WMS.

1. Improved Inventory Accuracy

One of the primary benefits of implementing a WMS is improved inventory accuracy. With a WMS in place, businesses can track and manage their inventory in real-time. The system provides accurate and up-to-date information on stock levels, locations, and movements. This ensures that businesses have a clear overview of their inventory, reducing the chances of inaccuracies, stockouts, or overstocking.

HCO Innovations offers cutting-edge WMS solutions that leverage advanced technologies like RFID (Radio Frequency Identification) and barcode scanning. These technologies enable businesses to accurately monitor inventory movements, ensuring that each item is recorded and accounted for at all times. This level of precision helps businesses to make informed decisions, optimize stock levels, and avoid unnecessary costs.

2. Increased Efficiency and Productivity

Implementing a WMS can significantly enhance warehouse efficiency and productivity. By automating manual processes and streamlining workflows, businesses can eliminate time-consuming tasks and reduce human errors. With a WMS, inventory management becomes more efficient, allowing employees to focus on value-added activities, such as fulfilling customer orders, improving order accuracy, and reducing order fulfillment times.

HCO Innovations’ WMS solutions are designed to streamline warehouse operations by optimizing picking routes, scheduling tasks, and automating inventory replenishment. Their innovative software not only improves the overall efficiency of warehouse operations but also increases the productivity of warehouse staff, ultimately leading to faster order fulfillment and increased customer satisfaction.

3. Enhanced Warehouse Visibility

A WMS provides businesses with enhanced visibility into their warehouse operations. With real-time data and reporting capabilities, businesses can gain valuable insights into their stock levels, order statuses, and overall warehouse performance. This visibility enables businesses to make proactive decisions, identify bottlenecks, and implement improvements to optimize their warehouse processes continuously.

HCO Innovations’ WMS solutions offer comprehensive reporting and analytics features, empowering businesses with actionable data-driven insights. By identifying trends, analyzing historical data, and monitoring key performance indicators (KPIs), businesses can make data-backed decisions to improve warehouse processes and address any inefficiencies.

HCO Innovations: Your Partner for Warehouse Optimization Solutions

When it comes to implementing a WMS for better inventory management, HCO Innovations is the go-to provider for cutting-edge warehouse optimization solutions. With years of industry experience and a deep understanding of warehouse operations, HCO Innovations offers a range of tailored solutions to meet the unique needs of businesses across various industries.

HCO Innovations’ WMS solutions are designed to enhance safety, productivity, efficiency, and cost-effectiveness within warehouse operations. Their innovative software integrates seamlessly with existing systems and workflows, ensuring a smooth transition and maximum utilization of resources. Whether you are a small business or a large enterprise, HCO Innovations has the expertise and solutions to optimize your warehouse operations.

By partnering with HCO Innovations, businesses can benefit from their expertise in warehouse optimization, advanced technologies, and commitment to customer satisfaction. Their team of professionals will work closely with you to understand your specific needs and goals, providing customized WMS solutions that align with your business requirements.

To learn more about HCO Innovations’ warehouse optimization solutions and how they can help your business achieve better inventory management, visit their website today.

What is WMS?

WMS stands for Warehouse Management System. It is a software application that helps businesses manage and control their warehouse operations more efficiently. With WMS, you can track inventory levels, optimize storage space, improve order fulfillment, and streamline supply chain processes.

Why is implementing a WMS important?

Implementing a WMS is important because it can significantly improve your inventory management. It helps eliminate manual processes and reduces errors, leading to better accuracy in inventory tracking. A WMS also provides real-time visibility into inventory levels, enabling you to make data-driven decisions and avoid stockouts or overstocks. It increases operational efficiency, reduces costs, and enhances customer satisfaction.

How do you choose the right WMS for your business?

Choosing the right WMS for your business depends on various factors. Start by assessing your specific business needs and requirements. Consider factors such as the size of your warehouse, the complexity of your operations, and the scalability you require. Evaluate different WMS solutions, looking at features, integrations, ease of use, and customer reviews. It's also important to consider your budget and implementation timeline.

What are the key features to look for in a WMS?

When selecting a WMS, look for key features such as inventory tracking and control, order management, receiving and putaway functionality, picking and packing optimization, real-time reporting and analytics, integration capabilities with other business systems (e.g., ERP), and scalability to accommodate your future growth.

How long does it take to implement a WMS?

The implementation timeline for a WMS can vary depending on factors such as the complexity of your operations, the size of your warehouse, and the readiness of your data. On average, it can take several weeks to a few months to implement a WMS. It involves tasks such as system configuration, data migration, employee training, and testing. It's advisable to work closely with the WMS provider and set realistic timelines based on your specific requirements.

Can a WMS integrate with other business systems?

Yes, a good WMS should have integration capabilities with other business systems such as ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), and e-commerce platforms. Integration enables seamless flow of data between different systems, eliminating the need for manual data entry and ensuring accurate and up-to-date information across your business.

What are the benefits of using a WMS for inventory management?

Using a WMS for inventory management has several benefits. It helps in reducing stockouts and overstocks, improving order accuracy and fulfillment rates, increasing warehouse efficiency and productivity, providing real-time visibility into inventory levels and locations, enabling better demand forecasting and planning, and enhancing overall customer satisfaction.

Is training required for using a WMS?

Yes, training is essential when implementing a WMS. It is important to provide training to your employees to ensure they understand how to use the system effectively. Training sessions can cover topics such as navigation within the WMS, performing key tasks like receiving and picking, using reporting and analytics features, and ensuring data accuracy. Training helps maximize the benefits and ROI of your WMS investment.

What are the cost considerations when implementing a WMS?

The cost considerations when implementing a WMS can include the software license fees, implementation and setup costs, hardware requirements, ongoing support and maintenance fees, training costs, and any customization or integration fees. It's important to evaluate the total cost of ownership and consider the long-term benefits and ROI of implementing a WMS.

Can a WMS be used for multiple warehouse locations?

Yes, a WMS can be used for multiple warehouse locations. Many WMS solutions offer multi-site support and can handle inventory management for multiple warehouses or distribution centers. This allows you to centrally manage your inventory, track stock levels across different locations, coordinate fulfillment operations, and gain centralized visibility into your entire supply chain.

Solutions for Minimizing Warehouse Costs Through Effective Space Utilization.

In today's fast-paced and competitive business environment, optimizing warehouse operations and minimizing costs are paramount to the success of any organization. Effective space utilization plays a crucial role in achieving these goals, as it directly impacts inventory management, productivity, and overall efficiency. HCO Innovations, a leading management consulting firm specializing in warehouse optimization and forklift fleet management, offers innovative and comprehensive solutions to help businesses maximize their warehouse space and reduce material handling costs.

The Importance of Effective Space Utilization in Warehouse Operations

Warehouses are the heart of supply chains, serving as storage facilities for products before they are distributed to end customers. Inefficient space utilization can lead to a variety of challenges and costs for businesses:

- Excess Inventory: Poor warehouse layout and space utilization can result in excessive inventory levels, tying up valuable capital and increasing carrying costs.

- Higher Operational Costs: Inefficient use of warehouse space leads to longer travel distances for forklifts and workers, increasing labor costs and fuel consumption.

- Reduced Productivity: A cluttered and disorganized warehouse can impede the flow of goods, cause errors, and slow down order fulfillment, resulting in decreased productivity.

- Poor Customer Service: Inadequate space utilization can lead to delays in order processing and inaccurate inventory counts, negatively impacting customer satisfaction.

HCO Innovations' Warehouse Optimization Solutions

HCO Innovations understands the challenges that businesses face when it comes to warehouse space utilization. Their team of experts employ a strategic and data-driven approach to identify inefficiencies and provide tailored solutions that optimize space utilization and reduce costs.

Here are some of the key solutions offered by HCO Innovations:

Warehouse Layout Evaluation and Design

HCO Innovations offers in-depth warehouse layout evaluation and design services to ensure every inch of available space is utilized efficiently. Their team assesses the current layout, workflows, and storage systems to identify opportunities for improvement. By reconfiguring the warehouse layout and implementing optimized storage solutions, businesses can maximize storage capacity while improving accessibility and order picking efficiency.

Safety Assessments and Compliance

Ensuring a safe work environment is essential in any warehouse operation. HCO Innovations conducts safety assessments to identify potential hazards, assess safety protocols, and implement necessary safety improvements. By creating a safe and compliant warehouse, businesses can reduce the risk of accidents, improve worker morale, and minimize associated costs.

Forklift Fleet Management

Managing a forklift fleet efficiently is crucial for optimizing warehouse operations. HCO Innovations offers comprehensive forklift fleet management solutions that include fleet analysis, preventive maintenance programs, operator training, and performance monitoring. By optimizing forklift fleet utilization and minimizing downtime, businesses can improve overall productivity and reduce maintenance and repair expenses.

Turnkey Maintenance Solutions

Equipment breakdowns can significantly impact warehouse operations and increase costs. HCO Innovations provides turnkey maintenance solutions to ensure equipment reliability and minimize downtime. Their proactive approach includes regular inspections, preventive maintenance, and rapid response to equipment failures. By implementing effective maintenance strategies, businesses can enhance equipment uptime, reduce repair costs, and prevent costly disruptions.

The Benefits of HCO Innovations' Warehouse Optimization Solutions

By partnering with HCO Innovations for warehouse optimization, businesses can experience a wide range of benefits:

- Increased Storage Capacity: Optimized warehouse layouts and storage solutions allow businesses to maximize their storage space, accommodating more inventory without the need for expansion.

- Improved Operational Efficiency: Streamlined workflows and optimized space utilization result in faster order processing, reduced travel time, and increased overall productivity.

- Enhanced Inventory Visibility and Accuracy: HCO Innovations' solutions help businesses implement effective inventory management systems, providing real-time visibility and accurate inventory counts.

- Reduced Material Handling Costs: By minimizing travel distances and improving warehouse efficiency, businesses can reduce labor costs, fuel consumption, and equipment maintenance expenses.

- Enhanced Safety and Compliance: Through safety assessments, training programs, and compliance measures, HCO Innovations helps businesses create safer work environments, reducing the risk of accidents and associated costs.

HCO Innovations leverages advanced cost-tracking software and their collaborative "boots on the ground" approach to deliver exceptional return on investment for their clients. Their expertise extends to various industries, including distribution, manufacturing, and food processing, allowing businesses from diverse sectors to benefit from their tailored solutions.

In conclusion, effective space utilization is crucial for achieving cost reductions and operational efficiency in warehouse operations. HCO Innovations provides comprehensive warehouse optimization solutions, ranging from layout evaluation and design to forklift fleet management and turnkey maintenance. By partnering with HCO Innovations, businesses can unlock the full potential of their warehouse space, minimize costs, and achieve sustainable long-term success.

Ready to optimize your warehouse operations and reduce material handling costs? Contact HCO Innovations here to schedule a consultation.