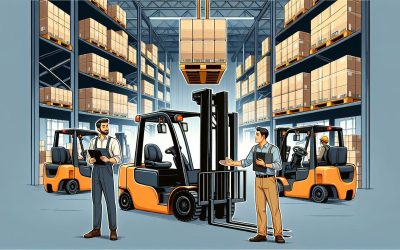

Forklifts can’t do their job without power. It’s that simple. You can have the cleanest layout,...

Optimize forklift power usage for energy savings and uptime.

Forklift Fleet Power Management

People – Equipment – Workflow

Forklift fleet power management is a service that helps facilities reduce energy waste, extend battery life, and optimize forklift charging practices. It’s ideal for warehouse managers, sustainability coordinators, and operations leaders managing electric forklift fleets.

We assess how your fleet uses power and recommend smarter charging schedules and battery maintenance programs that lower costs and boost performance. Our evaluations focus on:

- Battery charging patterns and station usage

- Power consumption tracking and load balancing

- Battery health, replacement schedules, and maintenance

- Energy-efficient charging infrastructure recommendations

- Best practices for operator charging behavior

This service ensures your electric fleet runs longer, charges smarter, and operates with fewer interruptions.

Electric Forklift Power Management for Cost and Efficiency Gains

Monitor Energy Consumption

Improve Battery Health

Optimize Charging Schedules

Learn More From Our Blog

How to Safely Transport Forklift Batteries

Transporting forklift batteries safely is crucial to ensure the smooth operation of warehouse...

How to Optimize Forklift Battery Charging Cycles

Charging a battery seems simple—plug it in, wait, unplug, repeat. But when you’re running a full...

Forklift Battery Safety: What You Need to Know

Forklifts play a crucial role in warehouse operations, facilitating the movement and...

The Benefits of Forklift Battery Standardization

In today's fast-paced warehouse operations, efficiency and productivity are paramount. Companies...

The Benefits of Lithium-Ion Batteries for Forklifts

Forklifts play a crucial role in warehouse operations, carrying heavy loads and ensuring smooth...

Why Choose HCO Innovations for Forklift Fleet Power Management?

HCO Innovations understands the impact power usage has on your fleet’s reliability and your facility’s energy budget. We bring deep experience in electric forklift operations, helping you implement battery strategies that extend equipment life and reduce utility costs. From data collection to actionable planning, we manage the details so you don’t have to.

- Energy audits tailored to electric forklift operations

- Battery health tracking and performance reporting

- Charging station usage analysis and optimization

- Cost reduction through smarter charging practices

- Sustainability insights and support for green initiatives

Whether you’re operating a small electric fleet or managing multiple facilities, we help you charge smarter and operate cleaner.