When it comes to warehousing operations, safety should always be a top priority. With the use of forklifts being an integral part of distribution centers, it is crucial to take proactive measures to improve forklift safety. By implementing effective strategies, companies can minimize the risk of accidents and ensure the well-being of both employees and equipment. In this article, we will discuss some practical tips to enhance forklift safety in distribution centers.

1. Provide Proper Training

One of the key factors in improving forklift safety is ensuring that all operators receive comprehensive training. Proper training should cover the safe operation of forklifts, including maneuvering, lifting, and stacking techniques. Operators should also be familiarized with the importance of following safety protocols, such as wearing seatbelts, using horns, and staying within designated areas.

It is essential to conduct regular training sessions and refresher courses to reinforce safe practices and address any new updates or regulations. Companies can also consider providing certifications for forklift operators, ensuring they have the necessary knowledge and skills to operate the equipment safely.

2. Regular Equipment Maintenance

Well-maintained forklifts play a significant role in ensuring safety within distribution centers. Regular maintenance checks should be performed to identify and address any mechanical issues or potential hazards. This includes inspecting brakes, tires, hydraulics, and electrical components.

Creating a preventive maintenance schedule and adhering to it helps prevent unexpected breakdowns and ensures that forklifts are in optimal working condition. Companies should also keep a record of maintenance activities and promptly address any identified issues to prevent them from escalating into safety hazards.

3. Implement Safety Protocols

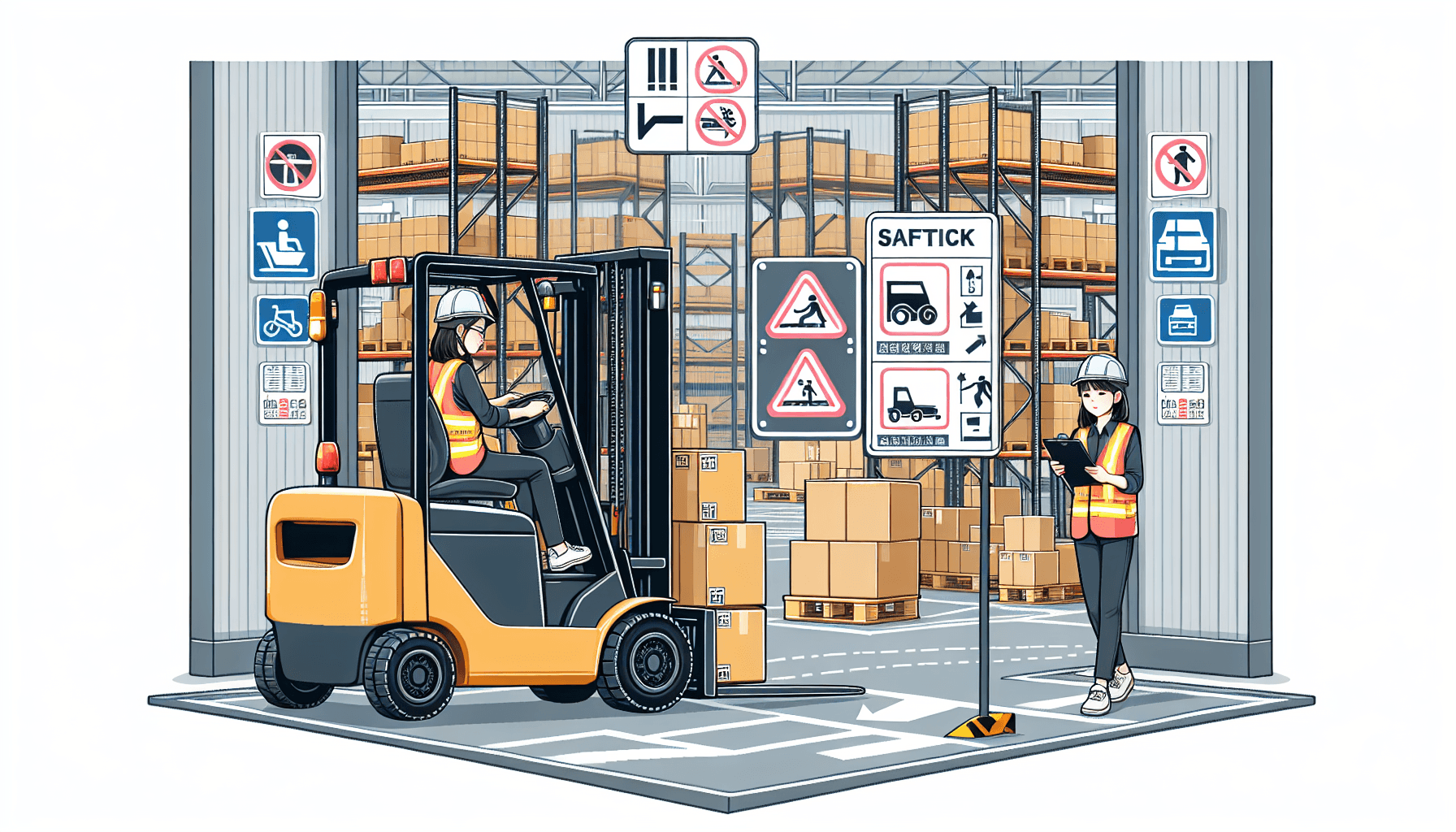

Establishing clear safety protocols and procedures is essential for creating a safe working environment. This can include guidelines for speed limits, traffic flow, proper loading and unloading practices, and equipment handling. Companies should regularly communicate and reinforce these protocols to employees through training sessions, signage, and safety meetings.

Creating designated pedestrian areas, separate from forklift traffic, can also help reduce the risk of accidents. Implementing barriers, such as guardrails or floor markings, can provide visual cues and help guide both pedestrians and forklift operators.

4. Use Technology to Enhance Safety

Advancements in technology have enabled the development of various tools and systems that can improve forklift safety. One such tool is proximity detection systems, which use sensors to detect the presence of pedestrians or obstacles near the forklift. These systems can alert the operator and even apply brakes automatically to prevent collisions.

Another technology that can enhance safety is forklift telemetry systems. These systems provide real-time monitoring of forklift operations, including speed, usage patterns, and potential safety violations. By analyzing the data gathered, companies can identify areas for improvement and implement measures to mitigate risks.

5. Regular Safety Audits and Evaluations

Regular safety audits and evaluations are vital to assess the effectiveness of existing safety measures and identify any gaps or areas that need improvement. These audits can involve checking compliance with safety protocols, inspecting equipment, and conducting interviews with forklift operators and other employees.

Consider partnering with a prominent provider of warehouse optimization solutions like HCO Innovations, who can offer a comprehensive warehouse safety evaluation. They can help identify potential hazards and provide recommendations to enhance safety within the distribution center. You can learn more about their warehouse safety evaluation services here.

Conclusion

Improving forklift safety in distribution centers is a crucial responsibility for companies. By providing proper training, conducting regular equipment maintenance, implementing safety protocols, using technology, and conducting regular safety audits, companies can significantly reduce the risk of accidents and create a safer working environment for everyone involved. Prioritizing forklift safety not only protects employees and equipment but also enhances overall productivity and efficiency within the warehouse operations.

What are the main causes of forklift accidents in distribution centers?

The main causes of forklift accidents in distribution centers include inadequate training of operators, poor maintenance of forklifts, lack of clear signage, congested work areas, and failure to follow established safety protocols.

How can I improve forklift safety in my distribution center?

To improve forklift safety in your distribution center, you can start by providing comprehensive training for forklift operators, ensuring regular maintenance and inspections of forklifts, implementing clear signage and floor markings, keeping work areas organized and free from clutter, and enforcing strict adherence to safety protocols.

What type of training should forklift operators receive?

Forklift operators should receive training on both the theoretical and practical aspects of operating a forklift. This includes understanding the safe operation of the forklift, load handling techniques, forklift maintenance procedures, and knowledge of relevant safety regulations. Additionally, operators should undergo periodic refresher training to stay up-to-date with best practices.

Why is regular maintenance of forklifts important for safety?

Regular maintenance of forklifts is crucial for safety because it helps identify and address any potential mechanical issues or malfunctions that could lead to accidents. Proper maintenance includes checking the brakes, tires, lights, steering, and other vital components of the forklift to ensure they are in good working condition.

How can I enhance visibility in my distribution center to prevent forklift accidents?

To enhance visibility in your distribution center, you can install adequate lighting in all work areas, use reflective or high-visibility paint for marking traffic lanes, implement clear warning signs and labels, and consider installing backup cameras or proximity sensors on forklifts to help operators see obstacles and pedestrians more easily.

What should I do if a forklift accident occurs in my distribution center?

If a forklift accident occurs in your distribution center, the first priority is to ensure the safety and well-being of anyone involved. Contact emergency services if necessary. Then, document the incident, gather witness statements, and investigate the root cause of the accident. Take corrective actions to prevent similar accidents in the future and review your safety protocols with all employees.

Are there any regulations or standards that dictate forklift safety in distribution centers?

Yes, there are regulations and standards in place to promote forklift safety in distribution centers. For example, OSHA (Occupational Safety and Health Administration) in the United States has specific guidelines regarding forklift safety, including training requirements and equipment standards. It is important to familiarize yourself with these regulations and ensure compliance in your distribution center.

What are some common forklift safety tips for operators?

Some common forklift safety tips for operators include wearing the appropriate personal protective equipment (PPE), conducting pre-operational inspections, using seatbelts, maintaining a safe speed, avoiding sudden stops and starts, never exceeding the lifting capacity of the forklift, and always being aware of their surroundings.

The Impact of Technology on Forklift Safety in Distribution Centers.

Warehouse optimization and forklift fleet management are crucial aspects of ensuring efficient operations in distribution centers. These facilities are responsible for storing and distributing goods for various industries, and their smooth functioning is vital for timely deliveries and customer satisfaction. Over the years, advancements in technology have greatly impacted the field of forklift safety, making it easier for distribution centers to streamline their operations and enhance overall efficiency.

The Role of Technology in Forklift Safety

Technology has revolutionized many industries, and the material handling industry is no exception. With the introduction of advanced software, systems, and equipment, distribution centers can now rely on technology to improve safety measures and minimize the risk of accidents involving forklifts. Let's explore some of the ways technology has transformed forklift safety:

1. Forklift Monitoring Systems

State-of-the-art forklift monitoring systems utilize sensors, cameras, and GPS technologies to track the movement, location, and performance of forklifts in real-time. These systems provide operators and managers with valuable data, enabling them to monitor and analyze forklift operations effectively. By identifying potential safety hazards, such as speeding, abrupt stops, or unauthorized access, these systems help to create a safer working environment.

2. Collision Avoidance Systems

Collisions involving forklifts can cause significant damage to goods, equipment, and most importantly, human lives. Newer forklift models are equipped with collision avoidance systems that use sensors and automatic braking technologies to detect obstacles and prevent collisions. These systems provide audio and visual alerts to the operators, giving them enough time to react and avoid accidents. By minimizing the risk of collisions, distribution centers can enhance forklift safety and reduce the potential for injuries or damage.

3. Training Simulators

Proper training is essential for forklift operators to handle these powerful machines safely. Training simulators provide a virtual environment where operators can practice their skills in a controlled setting. These simulators replicate real-world scenarios and allow operators to experience different challenging situations without any actual risks. By using simulators, operators can develop their handling techniques, improve their decision-making skills, and understand the importance of following safety procedures. This technology significantly contributes to reducing accidents caused by operator errors.

4. Proximity Sensors

Proximity sensors are becoming increasingly common in forklifts to enhance safety during operations. These sensors create a safety zone around the forklifts and alert the operators when they come too close to objects or individuals. By providing a clear indication of the forklift's proximity to potential hazards, these sensors help operators navigate through crowded or narrow spaces, reducing the chances of accidents and injuries.

5. Remote Monitoring and Control

Remote monitoring and control systems enable forklift operators and managers to remotely monitor and control forklifts from a centralized location. These systems allow real-time tracking of each forklift's movements, performance, and maintenance needs. This technology not only enhances safety by enabling immediate response to emergencies but also improves overall efficiency. For example, in the event of an accident or breakdown, operators can quickly alert the maintenance team and bring the forklift back into operation without delay.

Partnering with HCO Innovations for Forklift Safety

With the rapid advancements in technology, it is essential for distribution centers to stay updated and implement the latest forklift safety solutions. This is where HCO Innovations, a leading management consulting firm specializing in warehouse optimization and forklift fleet management, can be your trusted partner.

At HCO Innovations, we understand the importance of maintaining a safe and efficient working environment in distribution centers. Our team of experts is well-versed in the latest technological advancements and industry best practices for enhancing forklift safety. We offer comprehensive services that include warehouse layout evaluation, safety assessments, and turnkey maintenance solutions to help your distribution center achieve significant cost reductions and operational efficiency.

By leveraging advanced cost-tracking software and a collaborative "boots on the ground" approach, HCO Innovations ensures that your forklift fleet is optimized for safety and productivity. Our tailored solutions consistently deliver exceptional return on investment, making us the trusted choice for optimizing warehouse operations and reducing material handling costs.

Visit HCO Innovations to learn more about our services and how we can assist you in enhancing forklift safety in your distribution center.