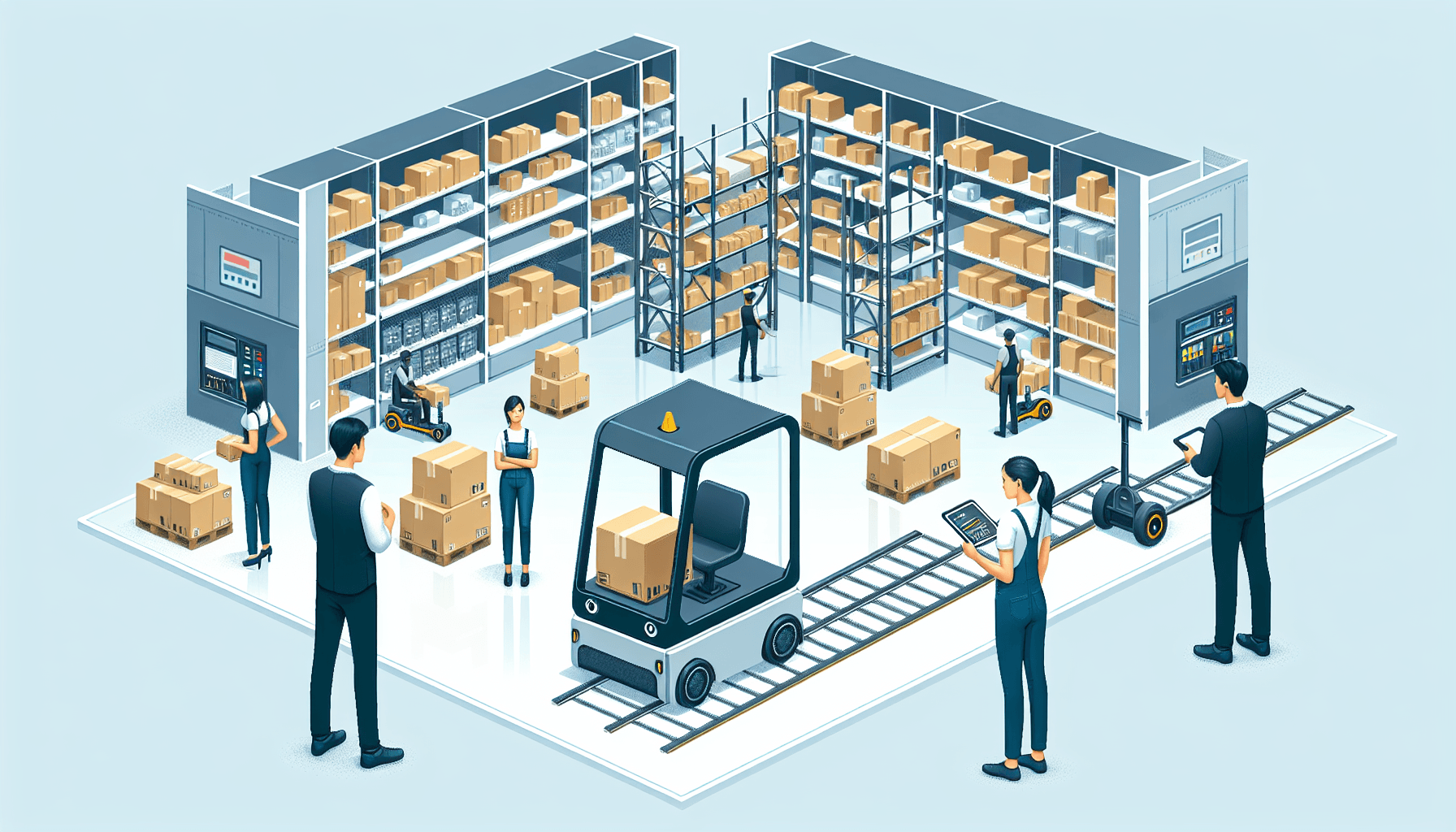

As technology continues to advance, warehouse operations are continually evolving to keep up with the demand for efficiency and productivity. One of the most significant advancements in warehouse automation is the integration of Autonomous Guided Vehicles (AGVs) into existing warehouse systems.

What are AGVs?

AGVs are robotic devices that are designed to operate autonomously and perform tasks within a warehouse environment. They are equipped with sensors and navigation systems that allow them to navigate through the warehouse, pick up and transport goods, and interact with other machinery and personnel.

AGVs can take many forms, including forklifts, carts, or even drones. They are programmed to follow specific routes, avoid obstacles, and perform tasks with precision and efficiency. By integrating AGVs into your existing warehouse system, you can streamline operations, increase productivity, and enhance overall efficiency.

Benefits of Integrating AGVs

Integrating AGVs into your existing warehouse system offers a wide range of benefits, including:

- Improved Safety: AGVs are equipped with advanced safety features such as collision avoidance systems and emergency stop capabilities. By replacing manual labor with AGVs, you can minimize the risk of accidents and injuries in the warehouse.

- Increased Efficiency: AGVs can operate 24/7 without breaks, reducing downtime and increasing overall efficiency. They can also optimize routes and reduce travel time, improving the speed at which goods are moved within the warehouse.

- Enhanced Productivity: With AGVs handling repetitive and mundane tasks, warehouse personnel can focus on more critical tasks that require human intervention. This leads to increased productivity and improved job satisfaction.

- Cost Savings: While the initial investment in AGVs may seem significant, their long-term benefits outweigh the costs. By reducing the need for manual labor and optimizing operations, integrating AGVs can result in significant cost savings over time.

Steps to Integrate AGVs

Integrating AGVs into your existing warehouse system requires careful planning and implementation. Here are the steps to follow:

- Evaluate Your Warehouse Needs: Understand your warehouse’s specific needs and identify areas where AGVs can enhance efficiency and productivity the most. Assess tasks that are repetitive, voluminous, or prone to errors.

- Choose the Right AGV System: There are various types of AGV systems available, each designed for specific applications. Consider factors such as payload capacity, navigation technology, battery life, and safety features when selecting the appropriate AGV system for your warehouse.

- Design AGV Paths and Layout: Determine the most efficient routes for AGVs within your warehouse. Consider factors such as traffic flow, the proximity of workstations, and any potential bottlenecks. Ensure that AGV paths are well-defined and integrated with existing infrastructure.

- Implement AGV Navigation and Control: Install the necessary infrastructure, such as navigation markers or magnetic strips, to guide AGVs along their designated paths. Set up a centralized control system that allows you to monitor and manage AGV operations effectively.

- Train Personnel and Adapt Workflows: Provide comprehensive training to your warehouse personnel on how to interact and work alongside AGVs safely. Adapt workflows and standard operating procedures to accommodate AGV integration.

- Monitor and Optimize Performance: Regularly monitor AGV performance and collect data on their operations. Use this data to identify areas for improvement, such as optimizing routes or adjusting work priorities.

Partnering with HCO Innovations

Integrating AGVs into your existing warehouse system can be a complex process, but with the right partner, the transition can be smooth and seamless. HCO Innovations offers comprehensive warehouse optimization solutions, including AGV deployment and integration.

With HCO Innovations’ expertise, you can maximize the benefits of AGVs and ensure a successful integration into your warehouse system. Their team of professionals will assess your specific needs, recommend the most suitable AGV system, and assist with the planning, implementation, and training stages.

To learn more about how HCO Innovations can help you integrate AGVs into your warehouse system, visit their website or contact their team of experts.