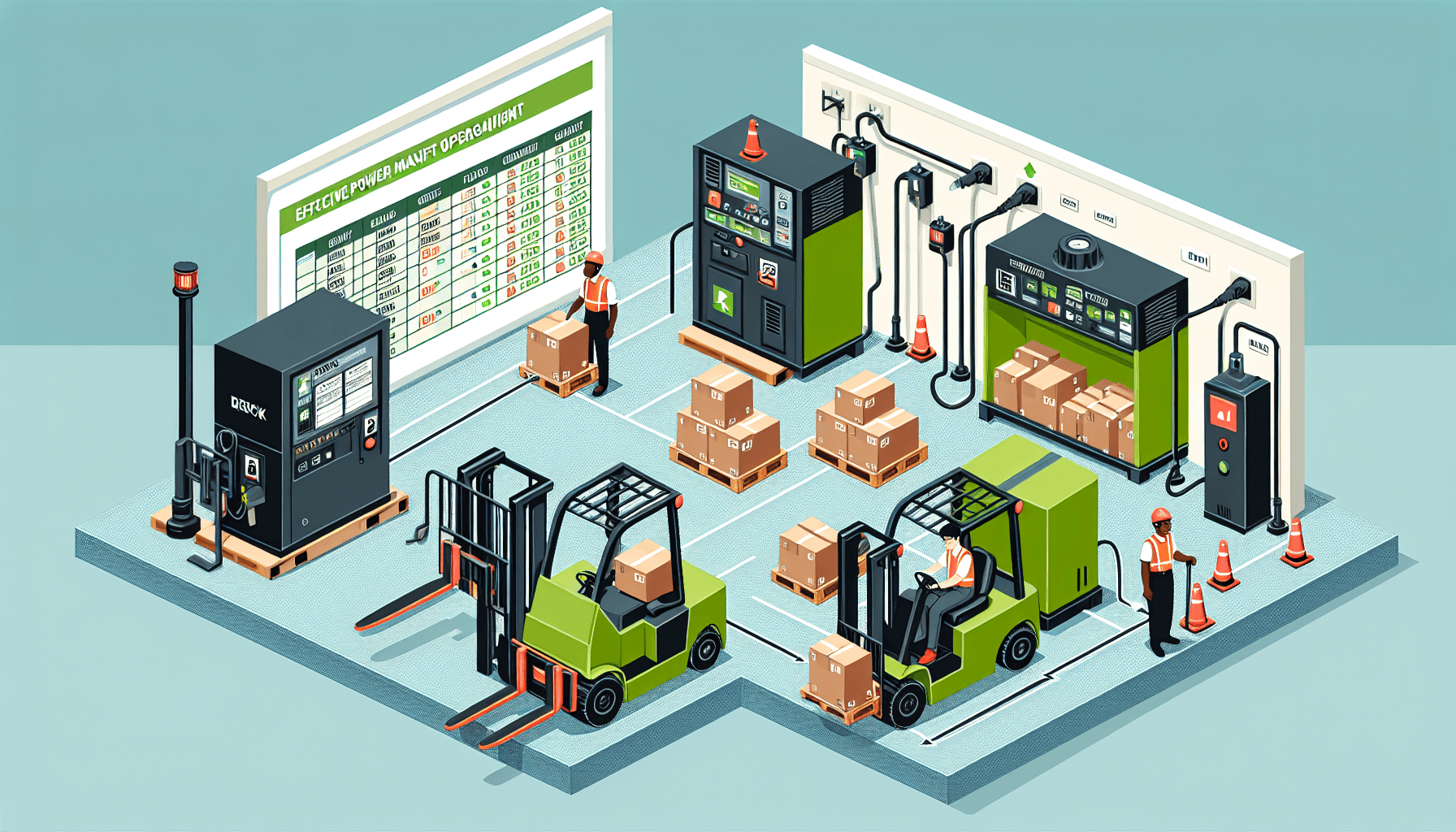

Managing forklift power is crucial for multi-shift operations in warehouses. With round-the-clock operations, it is important to optimize the power usage of forklifts to ensure productivity and efficiency. In this article, we will explore effective techniques to manage forklift power and maximize their functionality.

Regular Maintenance and Inspections

Regular maintenance and inspections are essential for ensuring the optimal performance of forklifts. By following a preventive maintenance schedule, you can detect and address any potential issues before they become major problems. This includes checking the power source, such as the battery, fuel, or electric charging system, to ensure it is functioning properly.

Regular maintenance and inspections also involve examining the tires, brakes, and hydraulic systems. Keep a record of the maintenance tasks and inspections performed to track the forklift’s condition and identify any patterns or potential areas of improvement. Well-maintained forklifts are less likely to experience power-related issues, which can lead to smooth operations and increased productivity.

Proper Training and Operator Education

Proper training and operator education are crucial for efficient forklift power management. Inadequate knowledge about the forklift’s power consumption, operation, and maintenance can result in unnecessary power wastage and premature wear and tear of components.

Ensure that all forklift operators receive comprehensive training on power management techniques, including operating the forklift within recommended speed limits, using the appropriate gears, and avoiding sudden accelerations or decelerations. Proper training will prevent excessive power consumption, maximize battery life, and reduce the need for frequent recharges or refueling.

Additionally, educate operators about best practices for proper charging or refueling procedures to ensure efficient power utilization. This includes charging batteries as recommended by the manufacturer, avoiding overcharging or undercharging, and following proper refueling guidelines. Operator awareness and adherence to these practices will significantly contribute to effective forklift power management.

Implementing Energy-Saving Technologies

Introducing energy-saving technologies and solutions can greatly enhance forklift power management in multi-shift operations. Here are some effective strategies:

1. LED Lighting:

Replace traditional lighting with energy-efficient LED lights in the warehouse. LED lights consume less power and emit minimal heat, which reduces the strain on the forklift’s power system. This results in improved overall energy efficiency.

2. Automatic Shutdown:

Implement automatic shutdown systems that power down inactive forklifts after a certain amount of idle time. This feature prevents power wastage, especially during breaks or when the forklift is not in use.

3. Telematics:

Integrate telematics systems into forklifts to track their power usage and identify potential areas of improvement. Telematics provide real-time insights into forklift performance, allowing operators to make informed decisions to optimize power consumption.

4. Battery Monitoring Systems:

Install battery monitoring systems that provide accurate data on the battery’s health and usage. These systems can detect potential issues, such as low charge levels, and alert operators, ensuring timely recharging or replacement to avoid disruptions in operations.

Implementing energy-saving technologies helps reduce power consumption, increase efficiency, and extend the lifespan of forklifts, ultimately leading to cost savings for the warehouse.

Optimizing Workload and Routes

Efficient workload management and route optimization can significantly impact forklift power management. By analyzing the warehouse layout and operations, you can identify ways to reduce unnecessary travel and minimize overall energy consumption.

Group tasks together to minimize the number of trips required by forklifts, reducing the time spent on the move and the associated power consumption. Streamline the pick and pack process to ensure optimized routes and minimize backtracking.

Utilize technology solutions such as warehouse management systems (WMS) and route planning software to optimize workflows and allocate tasks efficiently. These tools help to identify the best routes, reduce travel time, and enhance overall productivity while minimizing power usage.

Conclusion

Effectively managing forklift power in multi-shift operations is crucial for warehouse efficiency. By following a regular maintenance schedule, providing proper training to operators, implementing energy-saving technologies, and optimizing workload and routes, warehouses can ensure optimal forklift performance and reduce power wastage.

HCO Innovations, a leading provider of warehouse optimization solutions, offers comprehensive services to enhance forklift power management. Their expertise and innovative solutions can help warehouses improve safety, productivity, and cost-effectiveness within the operations.

What is the importance of managing forklift power for multi-shift operations?

Managing forklift power in multi-shift operations is crucial for maintaining productivity and ensuring the safety of workers. By properly managing forklift power, you can maximize uptime, reduce downtime, and prevent accidents or equipment failures.

What are some common challenges in managing forklift power for multi-shift operations?

There are several challenges in managing forklift power for multi-shift operations. Some common challenges include tracking battery charge levels, scheduling battery charging or replacement, optimizing battery usage, and dealing with potential power shortages during peak operating hours.

How can I track forklift battery charge levels?

To track forklift battery charge levels, you can use battery monitoring systems or tools that provide real-time data on battery charge levels. These systems often come with built-in indicators, display panels, or software that allows you to monitor the charge levels and plan for recharging or replacing batteries as needed.

What are some best practices for scheduling battery charging or replacement?

Some best practices for scheduling battery charging or replacement in multi-shift operations include creating a charging schedule that aligns with downtime periods, considering battery recharge time, rotating batteries between shifts, and having spare batteries available. It is also essential to train employees on proper battery handling and charging procedures.

How can I optimize forklift battery usage?

To optimize forklift battery usage, you can implement efficient driving practices, such as reducing unnecessary acceleration or idling, avoiding excessive load weight, and encouraging operators to use energy-saving features of the forklifts. Regular maintenance, including keeping batteries clean and properly watered, can also contribute to optimizing battery usage.

What can I do to prevent power shortages during peak operating hours?

To prevent power shortages during peak operating hours, you can consider implementing measures such as staggered break times to reduce the demand for charging, investing in fast-charging or opportunity-charging technologies, or even exploring alternative power sources such as hydrogen fuel cells. Analyzing your power requirements and capacity can help identify potential issues and plan for contingencies.

Are there any safety considerations when managing forklift power?

Absolutely! Safety should always be a top priority when managing forklift power. It's important to provide proper training to forklift operators on battery handling and charging procedures. Additionally, regular inspections of batteries, chargers, and electrical connections should be conducted to identify any potential safety hazards. Lastly, ensure that workers have access to proper personal protective equipment (PPE) when working with or around forklift power systems.

Forklift Safety Tips for New Operators

Operating a forklift requires skill, knowledge, and a commitment to safety. Whether you're a new forklift operator or have years of experience, it's crucial to stay updated on forklift safety practices and guidelines. At HCO Innovations, we understand the importance of forklift safety in warehouse operations. In this article, we will provide essential forklift safety tips for new operators to ensure a safe working environment for everyone.

1. Receive Proper Training

Before operating a forklift, it is crucial to receive proper training from a qualified instructor. Training should cover both theoretical aspects and practical skills such as maneuvering, lifting, and stacking loads. By undergoing comprehensive training, you will gain the necessary knowledge and skills to operate a forklift safely and efficiently.

2. Conduct Pre-Operational Inspections

Prior to using a forklift, always conduct a pre-operational inspection to ensure that the forklift is safe to operate. Check for any leaks, damaged parts, or mechanical issues. Ensure that the brakes, lights, horn, and other safety features are working correctly. Any defects or malfunctions should be reported immediately to the appropriate person or department for repairs.

3. Wear Appropriate Personal Protective Equipment (PPE)

When operating a forklift, it's essential to wear the appropriate personal protective equipment (PPE). This includes a hard hat, high-visibility vest, and steel-toed safety boots. PPE helps protect you from potential hazards and ensures your safety in case of accidents or incidents.

4. Observe Load Capacity and Stability

Each forklift has a designated load capacity that should never be exceeded. It is vital to understand the maximum load capacity of the forklift you are operating and adhere to it strictly. Overloading a forklift can affect its stability, making it prone to tipping over. Always ensure that the load is evenly distributed and secured properly before lifting or moving it.

5. Follow Safe Operating Procedures

Follow safe operating procedures at all times. This includes driving at a safe speed, maintaining a safe distance from other objects or vehicles, and using the forklift's horn when necessary. Avoid sudden starts, stops, or sharp turns that can compromise the stability of the forklift and cause accidents.

6. Be Aware of Surroundings

Maintain awareness of your surroundings while operating a forklift. Be mindful of pedestrians, other forklifts, and potential hazards such as obstacles, uneven surfaces, or slippery floors. Use mirrors and spotter assistance, if available, to ensure clear visibility in all directions.

7. Use Forklift Attachments Properly

If you need to use forklift attachments such as clamps, extensions, or rotators, make sure to use them properly and according to the manufacturer's instructions. Improper use of attachments can compromise the stability and safe operation of the forklift.

8. Park the Forklift Safely

When parking the forklift, always choose a designated parking area or spot. Engage the parking brake, lower the forks to the ground, and turn off the ignition. If necessary, put wheel chocks in place to prevent any unintended movement of the forklift.

9. Report Any Incidents or Near Misses

If you are involved in or witness any incidents or near misses while operating a forklift, it is essential to report them immediately. Reporting incidents and near misses helps identify potential safety hazards and allows for preventive measures to be implemented.

10. Regularly Maintain the Forklift

To ensure the optimal performance and safety of the forklift, it is crucial to follow a regular maintenance schedule. Regularly inspect and service the forklift according to the manufacturer's recommendations and guidelines. This includes checking fluid levels, tire pressure, and conducting routine maintenance and repairs.

By following these essential forklift safety tips, new operators can contribute to a safer work environment and reduce the risk of accidents. At HCO Innovations, we are committed to promoting forklift safety and helping our clients optimize their warehouse operations. Contact us today to learn more about our warehouse optimization and forklift fleet management services.