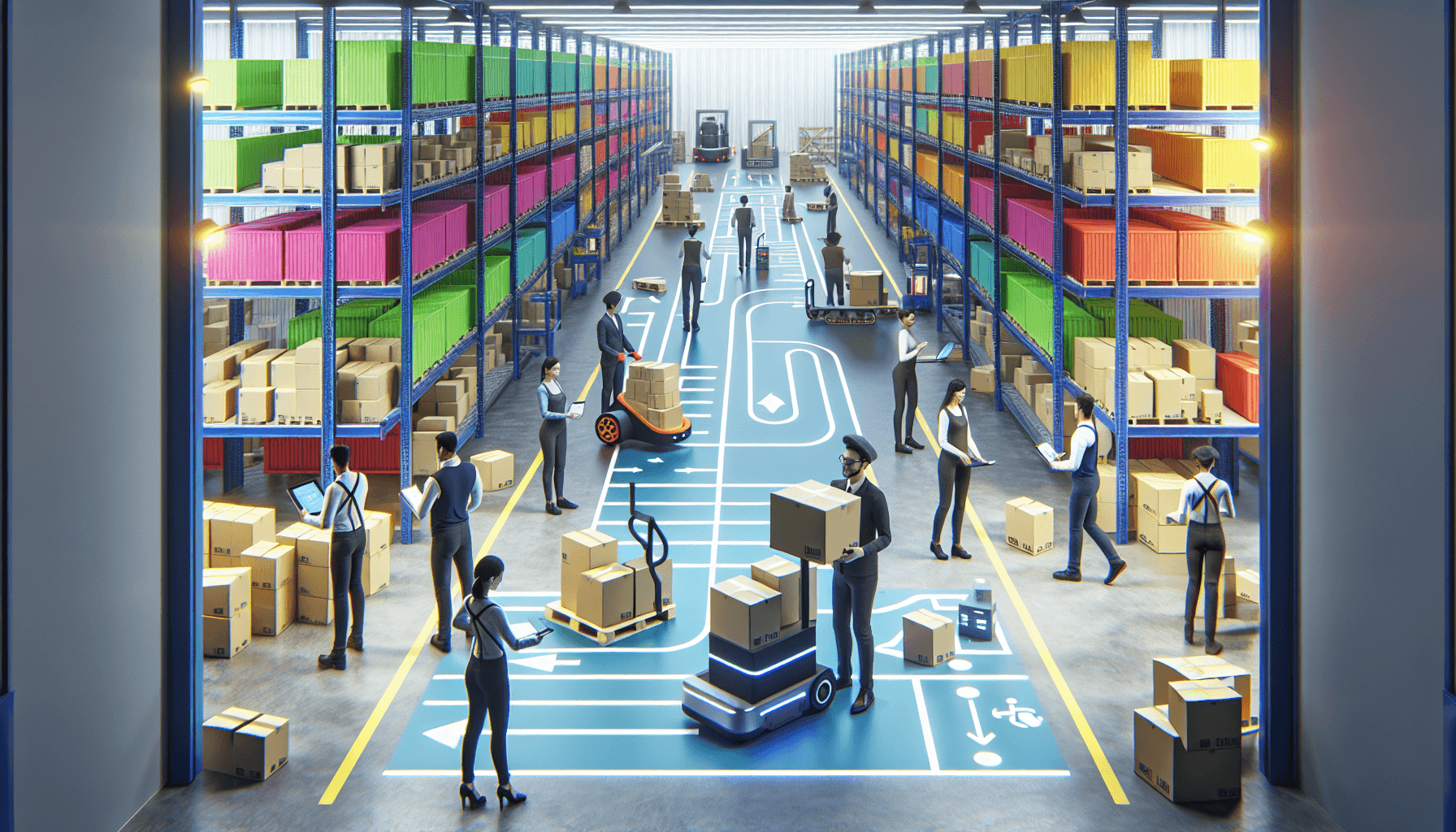

Warehouse operations can be complex and challenging, especially when it comes to efficiently managing material flow. In shared warehouses, where multiple companies store their products, optimizing material flow becomes even more crucial. By streamlining the movement of goods within a shared warehouse, companies can enhance productivity, reduce costs, and improve customer satisfaction.

The Importance of Material Flow Optimization

Efficient material flow is the backbone of any successful warehouse operation. It involves the smooth and timely movement of goods from receiving to storage, from storage to picking, and eventually to shipping. When material flow is optimized, it eliminates unnecessary delays, reduces errors, and maximizes the utilization of warehouse space.

Shared warehouses present unique challenges when it comes to material flow optimization. In these facilities, multiple companies share the same space, making it essential to ensure that each company’s goods are handled efficiently and separately. This requires careful planning and coordination to avoid bottlenecks, confusion, and potential mix-ups.

Here are some strategies to optimize material flow in shared warehouses:

1. Implement a Warehouse Management System (WMS)

A WMS is a software application that helps manage and control warehouse operations. It provides real-time visibility of inventory, automates processes, and facilitates efficient material flow. With a WMS in place, companies can track the movement of goods, monitor stock levels, and plan warehouse activities more effectively. This can lead to reduced lead times, improved picking accuracy, and enhanced overall efficiency.

2. Use Vertical Space Effectively

Shared warehouses often have limited floor space, which makes it crucial to utilize vertical space effectively. Implementing tall racks and shelving systems can help maximize storage capacity without expanding the warehouse footprint. This allows for better organization and easier access to products, reducing the time required for picking and replenishment.

Material flow evaluation is an essential step to identify areas where vertical space can be utilized more effectively. By analyzing the current flow of materials, companies can identify bottlenecks, congestion points, and areas of inefficiency. This insight enables them to design a layout that optimizes the use of vertical space, improving material flow and reducing unnecessary movement.

3. Implement Cross-Docking

Cross-docking is a logistics strategy that involves unloading products from incoming trucks or containers and loading them directly onto outbound vehicles for shipment, with minimal or no storage in between. This technique minimizes handling and storage costs while speeding up the material flow process. In a shared warehouse, implementing cross-docking can help separate and manage different companies’ goods more efficiently, reducing the need for extensive storage space.

4. Utilize Slotting Optimization

Slotting optimization involves strategically assigning products to specific locations within the warehouse based on various factors such as demand, size, and turnover rate. By placing frequently picked items closer to the shipping area, companies can reduce travel time and increase picking efficiency. In shared warehouses, slotting optimization becomes even more critical to ensure that each company’s products are easily accessible and well-organized.

5. Enhance Communication and Collaboration

Effective communication and collaboration between the different companies sharing the warehouse are key to optimizing material flow. By establishing clear processes, sharing information, and coordinating schedules, companies can avoid conflicts, optimize resource allocation, and minimize disruptions. This includes coordinating receiving and shipping schedules, standardizing labeling and packaging requirements, and aligning on best practices for material flow.

In conclusion, optimizing material flow in shared warehouses is essential for enhancing safety, productivity, efficiency, and cost-effectiveness. By implementing a robust warehouse management system, utilizing vertical space effectively, implementing cross-docking, utilizing slotting optimization, and enhancing communication and collaboration, companies can streamline material flow and achieve significant improvements in their warehouse operations.

For more insights and assistance in optimizing material flow in your warehouse, HCO Innovations offers material flow evaluation services. They specialize in providing warehouse optimization solutions that enhance safety, productivity, efficiency, and cost-effectiveness within warehouse operations. Visit their website for more information: https://www.hcoinnovations.com/material-flow-evaluation/.