When it comes to running e-commerce operations, efficient material handling equipment (MHE) management can be the key to success. Optimizing your MHE processes can help streamline operations, reduce costs, and improve overall efficiency. In this article, we will explore some strategies and best practices to optimize MHE for e-commerce operations.

1. Analyze and Assess Your Current MHE Setup

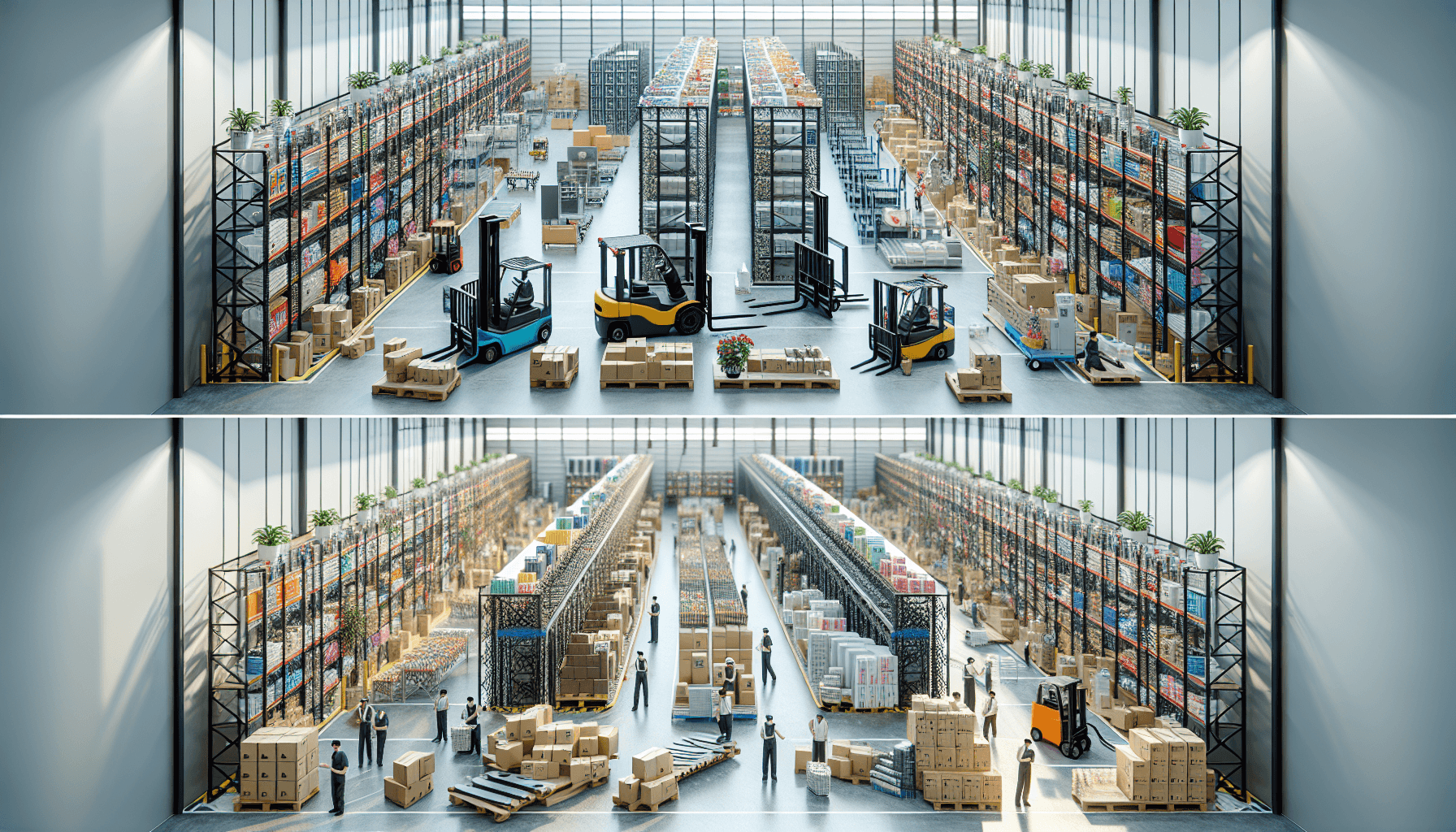

The first step in optimizing your MHE for e-commerce operations is to analyze and assess your current setup. Take a close look at your warehouse layout, equipment, and processes. Identify any bottlenecks, inefficiencies, or areas for improvement.

Consider the types of MHE you currently have, such as forklifts, pallet jacks, conveyors, and automated systems. Evaluate their condition, age, and performance. Are they meeting your current needs? Are they reliable and efficient?

Additionally, consider your warehouse layout. Are the picking and packing areas strategically located? Is the inventory storage optimized? Are there any unnecessary steps or movements that could be eliminated?

By thoroughly assessing your current MHE setup, you can identify areas that need improvement and develop a plan for optimization.

2. Choose the Right MHE for Your Needs

Once you have analyzed your current setup, it’s time to determine if you have the right MHE for your needs. As your e-commerce business grows and evolves, your MHE requirements may change.

Consider the specific needs of your e-commerce operations. Do you need MHE that can handle heavy loads? Are you dealing with fragile or sensitive products that require special handling? Do you have narrow aisles that require specialized equipment?

Research and explore different types of MHE available in the market. Consider factors such as load capacity, maneuverability, ease of use, and maintenance requirements. Choose MHE that meets your current requirements and has the potential to scale with your business.

For expert guidance in selecting the right MHE for your e-commerce operations, you can click here.

3. Embrace Automation and Robotics

In today’s fast-paced e-commerce environment, automation and robotics can revolutionize your MHE processes. Implementing advanced technologies like automated guided vehicles (AGVs), robotic pickers, and automated conveyor systems can significantly improve efficiency and accuracy.

Automation can help reduce labor costs, eliminate human errors, and expedite order fulfillment. AGVs can efficiently transport goods within the warehouse, freeing up human resources for more complex tasks. Robotic pickers can accurately and rapidly pick items from shelves, reducing picking time and increasing productivity.

However, it is important to carefully assess the cost-benefit analysis of implementing automation and robotics. Consider the upfront investment, ongoing maintenance, and the impact on your workforce. Automation should be strategically implemented to maximize its benefits.

4. Implement Warehouse Management Systems (WMS)

To optimize your MHE for e-commerce operations, it is essential to implement a robust warehouse management system (WMS). A WMS can provide real-time visibility and control over your inventory, orders, and MHE processes.

A WMS can help optimize inventory storage, improve order accuracy and fulfillment, and enhance overall operational efficiency. It can automate tasks such as inventory tracking, order routing, and resource allocation, reducing manual effort and minimizing errors.

Investing in a reliable and scalable WMS can streamline your MHE operations and provide valuable insights for continuous improvement.

5. Continuously Train and Educate Your Workforce

No matter how advanced your MHE setup is, it is essential to invest in training and educating your workforce. Your employees need to understand how to operate, maintain, and troubleshoot the MHE effectively.

Regular training sessions and refresher courses can help your workforce stay updated with the latest MHE technologies and best practices. Encourage a culture of continuous learning and improvement within your organization.

Properly trained employees can operate MHE efficiently, identify and address any issues promptly, and ensure the smooth functioning of your e-commerce operations.

Conclusion

Optimizing material handling equipment (MHE) for e-commerce operations is crucial to increase productivity, reduce costs, and improve overall efficiency. By analyzing your current setup, choosing the right MHE, embracing automation, implementing a robust warehouse management system, and investing in workforce training, you can optimize your MHE processes and drive success in your e-commerce operations.