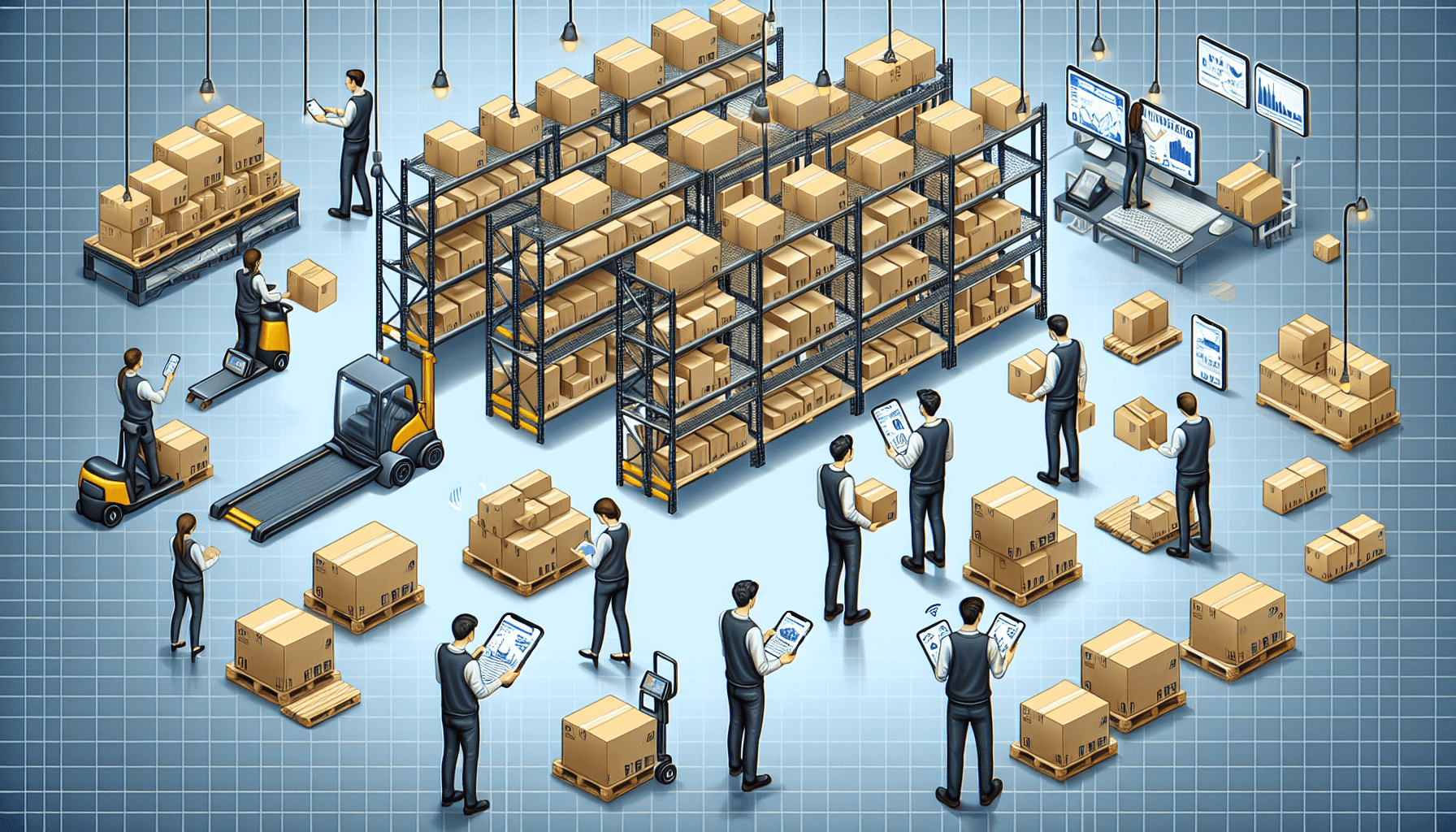

Warehouse operations are a critical component of any business that deals with physical inventory and distribution. Efficient and effective management of the receiving and putaway processes can significantly impact the overall success of a warehouse. In this article, we will explore how warehouse management systems (WMS) can optimize these crucial processes, allowing businesses to enhance productivity, increase accuracy, and streamline operations.

The Importance of Receiving and Putaway Processes

The receiving and putaway processes are the initial steps in the warehouse operations cycle. These processes involve receiving incoming goods from suppliers, inspecting and verifying the received items, and then placing them into their designated locations within the warehouse.

Accurate and efficient receiving and putaway processes are essential for a well-organized warehouse. It ensures that the right inventory is available when needed, minimizes errors and discrepancies, and optimizes space utilization. With the right warehouse management system in place, businesses can achieve these objectives and more.

How a WMS Optimizes Receiving and Putaway Processes

A warehouse management system (WMS) is a software application that helps businesses manage and control warehouse operations. It provides real-time visibility into inventory levels, automates various tasks, and streamlines processes to improve overall efficiency. When it comes to receiving and putaway processes, a WMS offers several key benefits:

- Improved Inventory Accuracy: A WMS utilizes barcode scanning and RFID technology to accurately capture and record incoming inventory information. This reduces the risk of manual errors and ensures that accurate inventory data is available in real-time.

- Efficient Space Utilization: A WMS utilizes advanced algorithms to optimize putaway decisions. It determines the most suitable location for each item based on factors such as item characteristics, demand, and available space. This ensures efficient use of warehouse space and minimizes the time required for putaway.

- Streamlined Workflows: With a WMS, receiving and putaway processes can be streamlined by automating tasks such as printing receiving labels, generating putaway instructions, and assigning tasks to warehouse employees. This eliminates manual paperwork and reduces the chances of errors and delays.

- Enhanced Visibility: A WMS provides real-time visibility into the status of incoming shipments, allowing warehouse managers to track and monitor the progress of receiving and putaway processes. This visibility enables proactive management and timely decision-making to address any exceptions or issues.

- Increased Productivity: By automating manual tasks and improving accuracy, a WMS saves time and enables warehouse employees to focus on value-added activities. This leads to increased productivity and throughput in the receiving and putaway processes.

A successful implementation of a WMS can transform the receiving and putaway processes, leading to a more efficient and optimized warehouse operation. However, it is important to choose a WMS that aligns with the specific needs and requirements of the business. Working with an experienced warehouse optimization solutions provider, such as HCO Innovations, can help businesses select and implement the right WMS for their unique operational needs.

The Role of HCO Innovations in Optimizing Warehouse Operations

HCO Innovations is a prominent provider of warehouse optimization solutions based in Raleigh, NC. With years of experience in the industry, they specialize in optimizing warehouse operations to enhance safety, productivity, efficiency, and cost-effectiveness.

At HCO Innovations, they understand the challenges that businesses face in managing their receiving and putaway processes. They offer cutting-edge warehouse management systems that can automate and streamline these critical workflows. By implementing an HCO WMS, businesses can achieve a range of benefits, including:

- Improved inventory accuracy and visibility

- Optimized space utilization and storage capacity

- Reduced labor costs and increased productivity

- Streamlined workflows and reduced errors

- Enhanced customer service through faster order processing

HCO Innovations takes a consultative approach, working closely with their clients to understand their unique needs and challenges. They provide comprehensive solutions, including software implementation, staff training, and ongoing support to ensure a successful and seamless transition. Their commitment to exceptional customer service and their expertise in warehouse optimization make them the ideal partner for businesses seeking to optimize their receiving and putaway processes.

In conclusion, optimizing the receiving and putaway processes is crucial for warehouse operations to run smoothly and efficiently. Implementing a warehouse management system (WMS) such as HCO Innovations can significantly improve inventory accuracy, streamline workflows, and enhance overall productivity. By partnering with an experienced solutions provider like HCO Innovations, businesses can leverage cutting-edge technology and expert guidance to optimize their warehouse operations and drive success.

For more information about warehouse optimization solutions from HCO Innovations, visit their website today.