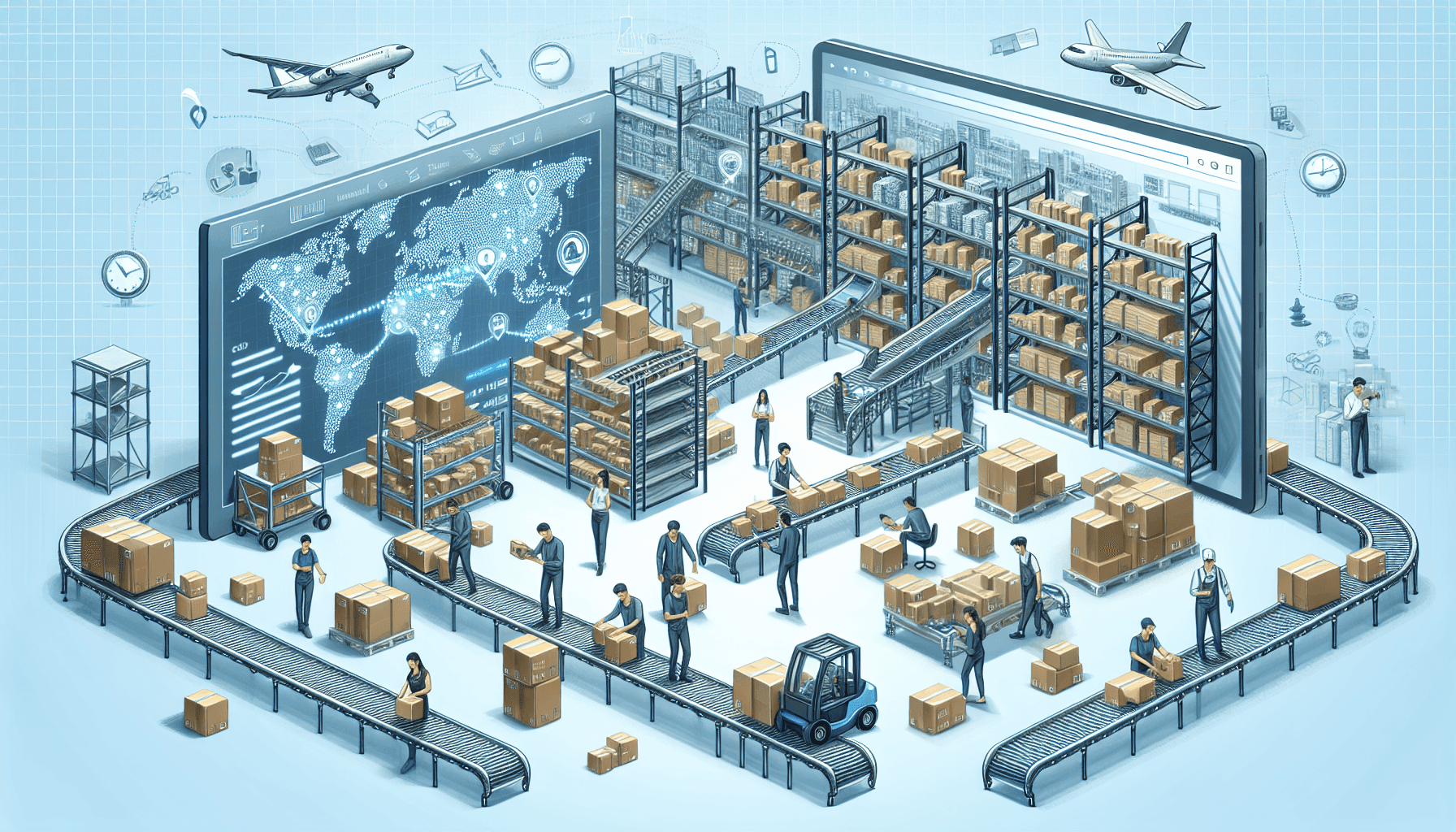

In the world of warehouse operations, efficiency and optimization are crucial factors that can make or break a company’s success. With the increasing demand for faster and more accurate order fulfillment, it is becoming more important than ever for businesses to optimize their warehouse networks for efficient distribution. By strategically organizing and managing warehouse resources, companies can improve productivity, reduce costs, and enhance customer satisfaction.

The Benefits of Warehouse Network Optimization

Warehouse network optimization involves evaluating and revamping the layout, processes, and technology of a company’s warehousing and distribution centers to maximize efficiency and effectiveness. This holistic approach considers various factors, such as product flow, inventory management, labor utilization, and transportation logistics, to create a well-optimized distribution network. Here are some key benefits of implementing warehouse network optimization:

- Improved Productivity: By streamlining processes and reducing unnecessary tasks or workarounds, warehouse network optimization helps eliminate bottlenecks and inefficiencies, leading to increased productivity and faster order fulfillment.

- Enhanced Safety: Optimal warehouse layout and equipment placement promote a safer work environment by reducing the risk of accidents, injuries, and product damage. This not only protects employees but also prevents lost time and costly liability claims.

- Cost Savings: Warehouse network optimization helps minimize operational costs through better space utilization, inventory management, and labor allocation. By optimizing the use of available resources, companies can lower their overall expenses and achieve better financial performance.

- Accelerated Order Fulfillment: By reducing order processing time, improving inventory visibility, and streamlining picking, packing, and shipping processes, warehouse network optimization enables faster and more accurate order fulfillment, leading to increased customer satisfaction.

To achieve these benefits, businesses need to implement effective warehouse network optimization strategies that align with their specific needs and objectives. This can involve the use of various technologies, such as warehouse management systems (WMS), automation, and robotics, to optimize and streamline warehouse operations.

The Process of Warehouse Network Optimization

Optimizing a warehouse network requires a systematic approach that involves analyzing and improving key aspects of the distribution process. Here is an overview of the typical steps involved in warehouse network optimization:

- Current State Assessment: The first step is to evaluate the existing warehouse network, including the layout, equipment, processes, and technology. This assessment helps identify inefficiencies, bottlenecks, and areas for improvement.

- Data Analysis: Gathering and analyzing data related to order volume, product flow, inventory levels, transportation costs, and customer demand is crucial for understanding the current network performance and identifying optimization opportunities.

- Network Design: Based on the data analysis, companies can redesign their warehouse network to optimize the flow of products, minimize distances traveled, and reduce handling and storage requirements. This may involve changes in warehouse location, layout, size, and the use of automation and technology.

- Process Improvement: Once the network design is finalized, companies can focus on improving specific processes within the warehouse, such as receiving, put-away, picking, packing, and shipping. This may involve implementing lean principles, standardizing procedures, and training employees on efficient workflow practices.

- Technology Integration: Leveraging technology solutions like warehouse management systems (WMS), inventory tracking systems, and automated material handling equipment can further enhance the efficiency and accuracy of warehouse operations.

- Continuous Monitoring and Optimization: Warehouse network optimization is an ongoing process that requires constant monitoring and fine-tuning. Companies should regularly analyze key performance indicators (KPIs), receive feedback from employees, and adapt their strategies based on changing business needs and market conditions.

Implementing warehouse network optimization can be a complex and resource-intensive task. That’s where companies like HCO Innovations come into play. With their expertise in warehouse optimization solutions, they can help businesses design and implement customized strategies to optimize their warehouse networks for efficient distribution. By leveraging state-of-the-art technology and industry best practices, HCO Innovations enables companies to enhance safety, productivity, efficiency, and cost-effectiveness within their warehouse operations.

If you’re looking to optimize your warehouse network and improve your distribution processes, reach out to HCO Innovations today. Visit their website here to learn more about their warehouse optimization solutions and how they can help you achieve your operational goals.