When it comes to warehouse operations, optimizing the warehouse network is crucial for success. A well-designed warehouse network can help improve the efficiency, productivity, and cost-effectiveness of your operations. It becomes even more important when dealing with a wide variety of products. In this article, we will discuss how to optimize your warehouse network for product variety.

Understanding Product Variety

Product variety refers to the diverse range of products that a warehouse handles. It can include different sizes, shapes, weights, fragility levels, and storage requirements. Dealing with a wide range of products requires careful planning and implementation to ensure smooth operations.

One of the key challenges in optimizing a warehouse network for product variety is the effective allocation of storage space. Different products may have different storage requirements, such as temperature control, special racks, or specialized handling equipment. Allocating the right storage space for each product type is essential to ensure their safety and accessibility.

Segmentation and Slotting

To optimize your warehouse network for product variety, start by segmenting your products based on their characteristics. This segmentation will help determine the specific storage requirements for each product group. For example, fragile or hazardous items may require separate storage areas with specialized handling procedures.

Once you have segmented your products, it’s important to implement an effective slotting strategy. Slotting involves determining the best location for each product within the warehouse based on factors such as demand, accessibility, and storage requirements. This helps minimize travel time and maximize productivity within the warehouse.

Consider using advanced slotting software or consulting with warehouse optimization specialists like HCO Innovations to assist you in optimizing your slotting strategy. They can provide insights and solutions tailored to your specific product variety and warehouse needs.

Warehouse Layout and Design

The layout and design of your warehouse play a crucial role in optimizing your network for product variety. A well-designed warehouse layout ensures efficient material flow, minimizes handling and travel distances, and maximizes space utilization.

When designing your warehouse layout, consider the specific requirements of each product group. For example, products that require temperature control should be located near the appropriate HVAC systems. Fragile items should be stored in a separate area to prevent damage during handling.

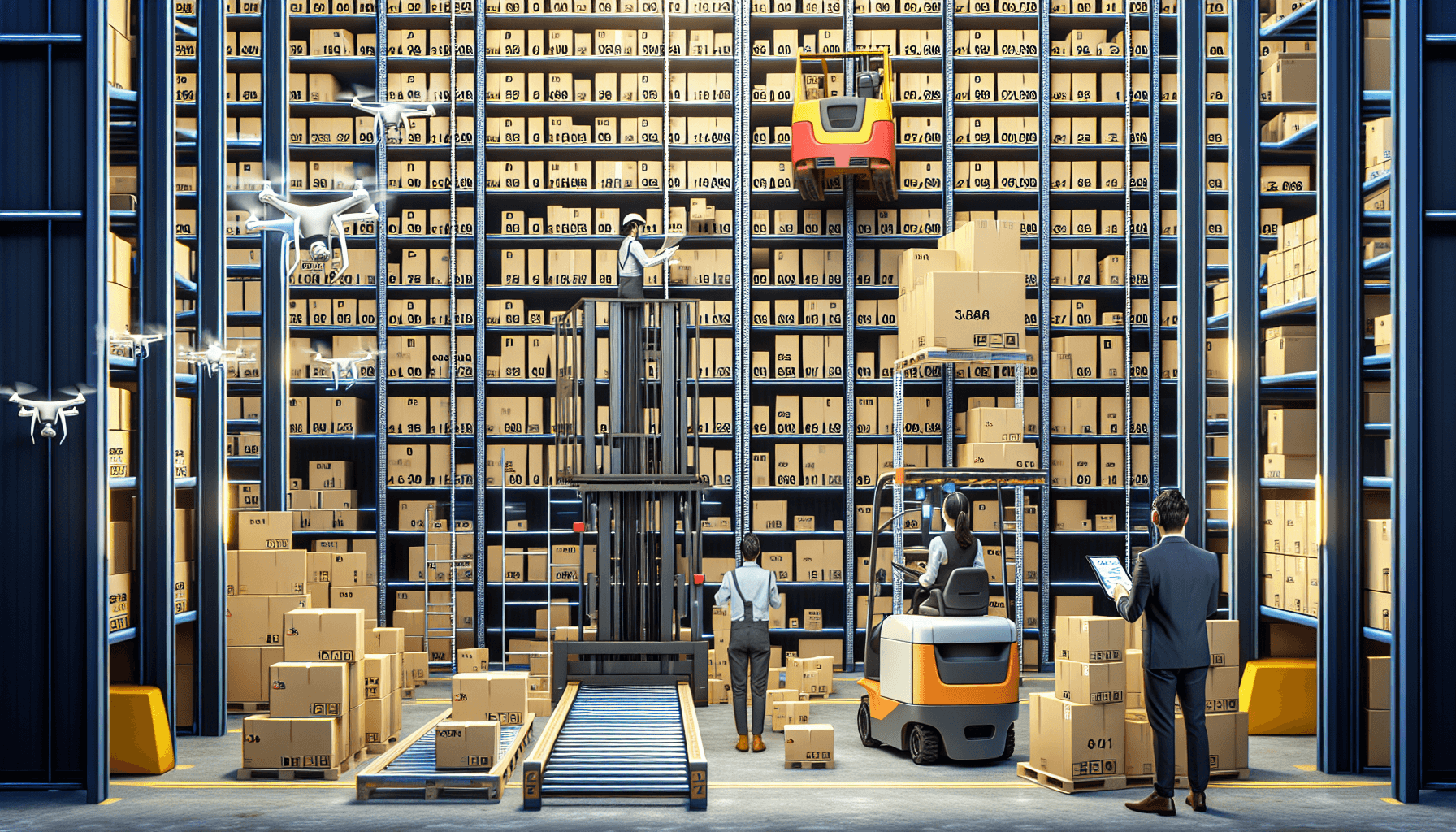

Investigate advanced technologies like automated storage and retrieval systems (AS/RS) and conveyor systems to improve warehouse efficiency and handle different product types effectively. These technologies can help reduce manual handling, minimize errors, and improve overall productivity.

Inventory Management and Forecasting

Optimizing your warehouse network for product variety also involves effective inventory management and forecasting. Accurate demand forecasting helps you plan your storage needs and allocate space accordingly. By analyzing historical data and market trends, you can anticipate demand fluctuations and adjust your inventory levels accordingly.

Implementing a robust inventory management system helps you track product availability, monitor stock levels, and reduce the risk of stockouts or overstocking. Utilize tools such as warehouse management systems (WMS) to streamline inventory processes, improve accuracy, and optimize product movement within the warehouse.

Continuous Improvement and Adaptability

Optimizing your warehouse network for product variety is an ongoing process. It requires continuous improvement and adaptability to changing market conditions and customer demands. Regularly review your warehouse operations, gather feedback from your team, and explore new technologies and strategies to enhance efficiency and productivity.

Consider partnering with warehouse optimization specialists like HCO Innovations to stay updated with the latest industry trends and best practices. They can provide customized solutions to address your specific challenges and help you achieve maximum optimization in your warehouse network.

Conclusion

Optimizing your warehouse network for product variety is essential for enhancing productivity, efficiency, and cost-effectiveness in your operations. Implementing effective segmentation and slotting strategies, designing an efficient layout, implementing advanced technologies, and utilizing robust inventory management systems are key steps in achieving optimization.

Remember that continuous improvement and adaptability are fundamental in maintaining an optimized warehouse network. Seek the assistance of experienced warehouse optimization specialists, such as HCO Innovations, to ensure you stay at the forefront of industry advancements and best practices.

What is warehouse network optimization?

Warehouse network optimization is the process of strategically designing and managing the distribution network of a company's warehouses to ensure efficient product flow, minimize costs, and maximize customer satisfaction.

Why is it important to optimize a warehouse network for product variety?

Optimizing a warehouse network for product variety is crucial because it helps businesses meet the diverse needs of their customers. By strategically organizing warehouses and inventory, companies can ensure that a wide range of products is available when and where customers need them, leading to increased sales and customer satisfaction.

How can I determine the best locations for my warehouses?

There are several factors to consider when determining the best locations for your warehouses. These include proximity to customers, transportation infrastructure, access to suppliers, labor availability, and government regulations. Conducting market research and analyzing data can help identify potential locations that align with your business goals and customer base.

What are some strategies for optimizing warehouse space for product variety?

There are multiple strategies to optimize warehouse space for product variety. Implementing efficient inventory management practices, such as ABC analysis and just-in-time inventory, can help reduce excess stock and maximize available space. Additionally, utilizing vertical storage solutions, implementing flexible racking systems, and optimizing workflow processes can enhance the warehouse's capacity to accommodate a diverse range of products.

How can warehouse automation help optimize product variety?

Warehouse automation can significantly contribute to optimizing product variety. Automated systems, such as robotic picking and sorting, can improve order accuracy, reduce human error, and increase operational efficiency. By streamlining processes and eliminating manual tasks, warehouse automation allows for faster handling of diverse products, leading to improved productivity and customer satisfaction.

What role does technology play in optimizing warehouse networks for product variety?

Technology plays a crucial role in optimizing warehouse networks for product variety. Warehouse management systems (WMS) provide real-time visibility into inventory levels, order status, and warehouse operations. Advanced analytics tools can offer insights into demand patterns, allowing businesses to make informed decisions regarding inventory placement and product assortment. Additionally, technologies like barcode scanning, RFID, and cloud-based platforms enhance accuracy, traceability, and collaboration within the warehouse network.

Optimizing Warehouse Layout for Efficient Inventory Management.

In today's fast-paced business world, efficient inventory management is crucial for the success and profitability of any company. A well-optimized warehouse layout plays a significant role in achieving this objective. By strategically organizing your inventory and streamlining the flow of goods, you can enhance productivity, reduce costs, and meet customer demands more effectively.

The Importance of Warehouse Layout Optimization

The layout of your warehouse directly impacts the efficiency of your operations. A poorly designed layout can lead to wasted time, increased labor costs, and product damage. On the other hand, an optimized warehouse layout can result in:

- Improved inventory visibility

- Reduced travel distance for employees and forklift operators

- Enhanced order fulfillment speed

- Minimized handling and picking errors

- Increased warehouse capacity and storage density

With so much at stake, it is crucial to partner with a reputable management consulting firm like HCO Innovations to optimize your warehouse layout and achieve maximum efficiency.

Key Considerations for Warehouse Layout Optimization

When it comes to warehouse layout optimization, several factors need to be taken into account:

1. Inventory Analysis and Classification

Before designing your warehouse layout, it is important to conduct a comprehensive inventory analysis. This involves categorizing your inventory based on its size, weight, fragility, and demand frequency. By classifying your inventory, you can determine the appropriate storage methods and allocate space accordingly.

2. Safety and Compliance

Warehouse safety should always be a top priority. Your layout should consider safety measures such as clear aisle widths, proper lighting, and well-marked walkways. Additionally, compliance with industry standards and regulations is essential to avoid penalties and maintain a safe work environment.

3. Flow of Goods

The flow of goods within your warehouse should be optimized to minimize bottlenecks and maximize efficiency. This involves analyzing the movement of goods from receiving to storage, picking, packing, and shipping. By mapping out these processes, you can identify areas for improvement and implement a layout that promotes smooth and seamless operations.

4. Utilization of Space

A well-designed layout makes the most efficient use of available space. By utilizing vertical space through the use of racking systems or mezzanines, you can increase your storage capacity without expanding your physical footprint. Additionally, considering factors like rotation, size, and accessibility when positioning your inventory can optimize the utilization of both floor and vertical space.

5. Technology Integration

Incorporating advanced technologies like warehouse management systems (WMS) and automated material handling equipment can significantly improve the efficiency of your warehouse operations. These technologies can streamline processes, reduce human errors, and provide real-time data for better decision-making.

HCO Innovations: Your Partner in Warehouse Optimization

When it comes to warehouse layout optimization and efficient inventory management, HCO Innovations has a proven track record of success. With years of experience in the field, they have helped numerous companies across various industries achieve significant cost reductions and operational efficiency.

HCO Innovations takes a meticulous approach to warehouse optimization. Their team of experts conducts on-site evaluations to understand your specific needs and challenges. They leverage advanced cost-tracking software and employ a collaborative "boots on the ground" approach to develop tailored solutions that address your unique requirements.

By leveraging their expertise, HCO Innovations can help you:

- Optimize your warehouse layout for maximum efficiency

- Implement safety measures to comply with industry regulations

- Streamline the flow of goods for faster order fulfillment

- Maximize storage capacity and utilize space effectively

- Integrate advanced technologies for improved productivity

With HCO Innovations as your partner, you can achieve exceptional return on investment and take your warehouse operations to new heights.

Unlock the full potential of your warehouse by optimizing its layout and implementing efficient inventory management practices. Contact HCO Innovations today and take the first step towards a more productive and profitable warehouse.