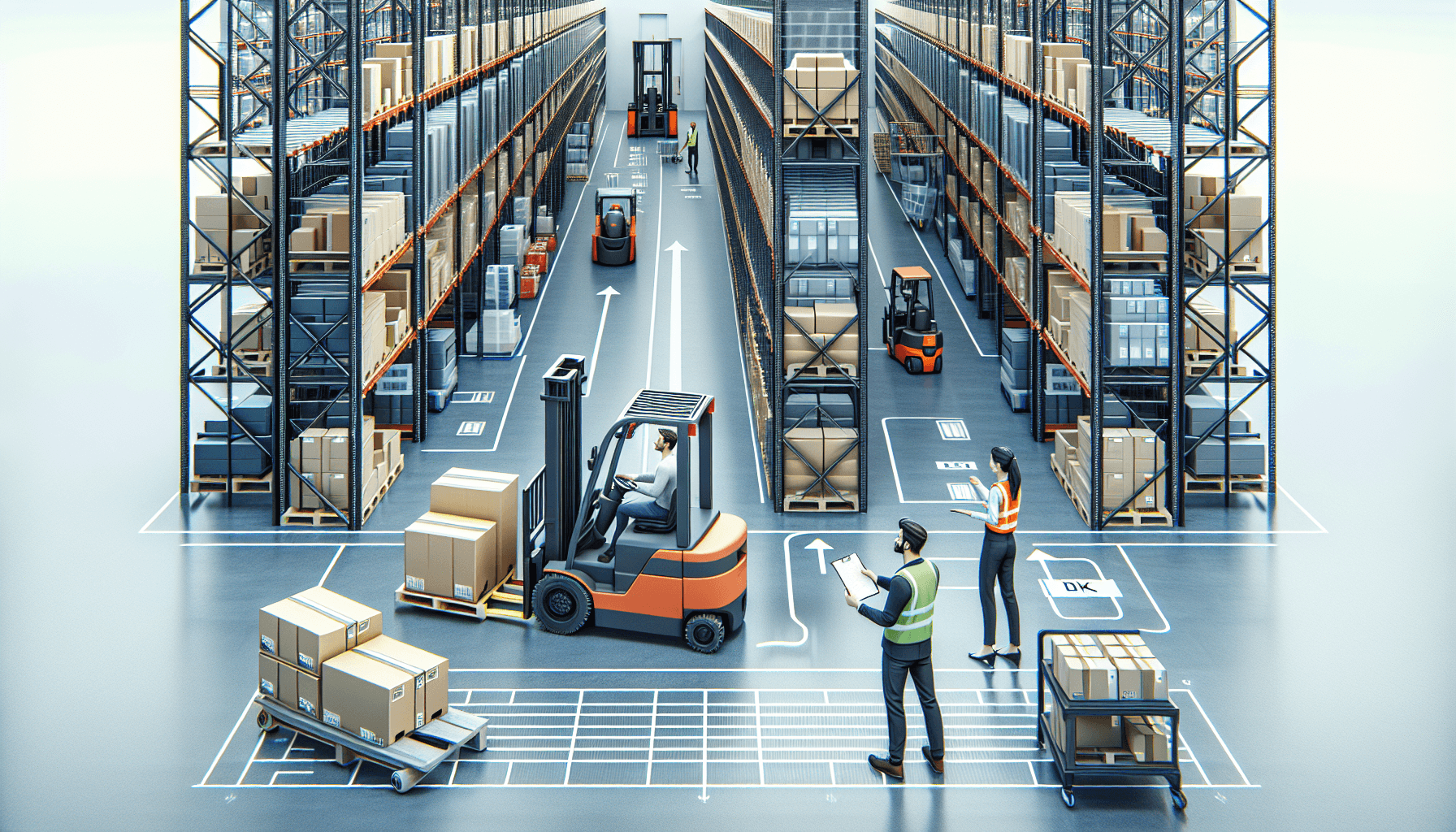

When it comes to warehouse operations, optimizing your warehouse layout is crucial. A well-optimized warehouse layout can significantly improve safety, productivity, efficiency, and cost-effectiveness. One key aspect of warehouse layout optimization is optimizing pallet storage. In this article, we will explore different strategies and best practices to optimize your warehouse layout specifically for pallet storage.

1. Analyze your current warehouse layout

The first step in optimizing your warehouse layout for pallet storage is to analyze your current setup. Evaluate how your pallets are currently stored and identify any areas for improvement. This could include inefficient use of space, overcrowding, or lack of organization.

Warehouse layout evaluation can help you gain insights into your current setup. By working with professionals who specialize in warehouse optimization, you can identify the strengths and weaknesses of your current layout and develop a plan for improvement.

2. Utilize vertical space

When it comes to pallet storage, utilizing vertical space is key. Many warehouses have high ceilings that aren’t fully utilized. Consider implementing taller storage racks or mezzanines to maximize vertical storage capacity. This can help free up valuable floor space while still allowing easy access to your inventory.

Additionally, consider investing in equipment such as forklifts or reach trucks that can safely and efficiently reach higher shelves. This will enable you to store more pallets vertically without sacrificing accessibility.

3. Implement proper labeling and organization

Proper labeling and organization play a crucial role in optimizing pallet storage. Clear and consistent labeling allows for easy identification and tracking of inventory. Implement a standardized labeling system that includes information such as product code, quantity, and location.

Organize your pallets based on factors such as product type, popularity, or expiration date to optimize picking and retrieval processes. Consider implementing color-coded systems or barcode scanning technology to streamline inventory management.

4. Optimize aisle width

The width of your aisles can greatly impact the efficiency of your warehouse operations. Narrower aisle widths can maximize storage capacity but may limit accessibility and maneuverability. On the other hand, wider aisles may be necessary for larger equipment or high-traffic areas.

Analyze your inventory and equipment needs to determine the appropriate aisle width for each section of your warehouse. Consider utilizing different aisle width configurations based on the type of products and storage systems being used.

5. Implement a FIFO (First-In, First-Out) system

For warehouses dealing with perishable or time-sensitive goods, implementing a FIFO system is vital. This system ensures that older inventory is used or shipped out before newer items, reducing the risk of product spoilage or obsolescence.

Designate specific areas or shelves for incoming pallets and implement a clear rotation policy. This will help ensure that the oldest pallets are always in the front and are the first to be picked or shipped.

6. Invest in warehouse management software

Warehouse management software can greatly facilitate the optimization of your warehouse layout for pallet storage. These software solutions offer features such as inventory tracking, order management, and real-time reporting.

By implementing a capable warehouse management system, you can streamline operations, improve accuracy, and reduce costs. It will provide you with valuable insights into your inventory levels, space utilization, and overall warehouse performance.

7. Regularly review and adjust your layout

Warehouse optimization is an ongoing process. It’s crucial to regularly review and adjust your layout to accommodate changes in inventory, customer demand, or operational requirements.

Conduct routine audits to identify any inefficiencies or bottlenecks in your pallet storage system. Seek feedback from your warehouse staff and consider their suggestions for improvement. This will help you continuously optimize your warehouse layout and stay ahead of evolving business needs.

In conclusion, optimizing your warehouse layout for pallet storage is essential for warehouse efficiency and cost-effectiveness. By analyzing your current layout, utilizing vertical space, implementing proper labeling and organization, optimizing aisle width, implementing a FIFO system, investing in warehouse management software, and regularly reviewing and adjusting your layout, you can create a well-optimized warehouse that maximizes pallet storage capacity while ensuring easy accessibility and efficient operations.

Ready to evaluate and optimize your warehouse layout? Contact HCO Innovations today to learn more about our warehouse optimization solutions!

What is the importance of optimizing warehouse layout for pallet storage?

Optimizing your warehouse layout for pallet storage is crucial for maximizing space utilization, enhancing operational efficiency, and improving overall productivity. By organizing your pallets in a strategic manner, you can optimize workflows, reduce picking and storage time, minimize handling costs, and ensure easy accessibility to inventory.

How can I determine the right warehouse layout for pallet storage?

Determining the right warehouse layout for pallet storage involves considering factors such as the type of products stored, volume of inventory, material handling equipment, and workflow patterns. Conducting a thorough analysis of your inventory, reviewing order patterns, and consulting with warehouse experts can help identify the most suitable layout design for your specific needs.

What are some common warehouse layout options for pallet storage?

There are several common warehouse layout options for pallet storage, including selective racking, double-deep racking, drive-in racking, push-back racking, pallet flow racking, and automated storage and retrieval systems (AS/RS). Each option has its pros and cons, and the choice depends on factors such as inventory turnover, space availability, accessibility requirements, and budget.

How can I optimize space utilization in my warehouse for pallet storage?

To optimize space utilization in your warehouse for pallet storage, consider implementing techniques such as stacking pallets vertically, utilizing narrow aisles, installing mezzanine floors, implementing flow racks, and using high-density storage systems. These methods can help maximize your available space and increase storage capacity without the need for excessive warehouse expansion.

What safety precautions should I consider when optimizing warehouse layout for pallet storage?

When optimizing your warehouse layout for pallet storage, it's essential to prioritize safety. Ensure that aisles are wide enough to accommodate forklifts, use proper signage for clear navigation, implement safety barriers and guardrails to prevent accidents, and train your staff on safe handling and storage practices. Regular maintenance of racks and equipment is also crucial to minimize the risk of accidents.

How can I improve the efficiency of picking and storing pallets?

To improve the efficiency of picking and storing pallets, consider implementing strategies such as proper labeling and barcoding of pallets, organizing inventory based on product popularity or frequency of use, implementing a logical numbering or slotting system, utilizing inventory management software for accurate tracking, and training staff on efficient picking techniques and best practices.

Is it worth investing in automated storage systems for pallet storage?

Investing in automated storage systems for pallet storage can be a worthwhile choice if you have a high volume of inventory, require fast order fulfillment, and have a need for precise inventory tracking. Automated systems like AS/RS can significantly increase efficiency, reduce labor costs, and optimize space utilization by utilizing robotic systems for pallet handling, retrieval, and storage.

What are some additional tips for optimizing warehouse layout for pallet storage?

Some additional tips for optimizing warehouse layout for pallet storage include implementing a regular maintenance program for racks and equipment, conducting frequent inventory audits to identify obsolete or slow-moving items, streamlining processes through continuous improvement initiatives, and regularly monitoring and assessing the efficiency of your warehouse operations to identify areas for further optimization.

How to Streamline Inventory Management in Your Warehouse.

Are you looking for ways to optimize your warehouse operations and streamline your inventory management? Look no further! At HCO Innovations, we specialize in warehouse optimization and forklift fleet management, helping businesses across various industries achieve significant cost reductions and operational efficiency. With our comprehensive services, including warehouse layout evaluation, safety assessments, and turnkey maintenance solutions, we are your trusted partner for improving warehouse efficiency and reducing material handling costs.

The Importance of Streamlined Inventory Management

Effective inventory management is critical for the smooth functioning of any warehouse operation. Poor inventory management can lead to stockouts, excess inventory, order fulfillment delays, and increased carrying costs. To avoid these challenges, it is crucial to streamline your inventory management processes. Here are some key reasons why streamlined inventory management is essential:

- Improved Customer Satisfaction: By accurately tracking inventory levels and ensuring stock availability, you can fulfill customer orders promptly, resulting in higher customer satisfaction rates and improved customer loyalty.

- Reduced Carrying Costs: Excess inventory ties up capital and incurs costs for storage and maintenance. Streamlining your inventory management helps optimize stock levels, reducing carrying costs and freeing up capital that can be invested in other areas of your business.

- Minimized Stockouts and Lost Sales: By having real-time visibility into your inventory levels and demand patterns, you can better anticipate customer needs and avoid stockouts. This reduces the risk of lost sales and potential damage to your reputation.

- Increased Operational Efficiency: By implementing efficient inventory management practices, such as proper stock organization, optimized picking and replenishment procedures, and automated inventory tracking, you can improve overall warehouse efficiency and productivity.

- Accurate Demand Forecasting: Streamlined inventory management enables you to gather accurate data on demand patterns, allowing you to forecast future demand more accurately. This helps in planning production, purchasing, and stock replenishment activities.

HCO Innovations understands the importance of efficient inventory management and offers tailored solutions to help you optimize your warehouse operations. Our team of experts will analyze your current inventory management processes, identify areas for improvement, and implement strategies to streamline your operations.

Key Steps to Streamline Inventory Management

Now that you understand the significance of streamlined inventory management, let's explore some key steps you can take to optimize your warehouse operations:

1. Conduct a Comprehensive Inventory Audit

The first step in streamlining inventory management is to conduct a thorough audit of your current inventory. This includes assessing the accuracy of your inventory records, identifying obsolete or slow-moving inventory, and reconciling any discrepancies. This audit will provide you with valuable insights into your inventory levels, allowing you to make informed decisions regarding stock replenishment and elimination of excess inventory.

2. Implement an Inventory Management System

An inventory management system is a crucial tool for streamlining inventory operations. It allows you to track inventory levels in real-time, automate reordering processes, generate reports, and gain better visibility into your warehouse operations. Choosing the right system for your business needs is essential to ensure seamless inventory management.

3. Optimize Warehouse Layout and Organization

A well-organized warehouse layout is essential for efficient inventory management. Analyze your warehouse layout to ensure optimal placement of stock, efficient flow of goods, and easy accessibility. This will minimize picking and replenishment time, reduce the risk of errors, and improve overall operational efficiency.

4. Implement Barcode or RFID Technology

Barcode or RFID technology enables accurate and efficient inventory tracking. By using scanners or readers, you can quickly update inventory levels, track stock movement, and conduct regular cycle counts. This eliminates manual errors, enhances inventory accuracy, and improves overall inventory management processes.

5. Establish Reorder Points and Safety Stock Levels

Setting up reorder points and safety stock levels ensure that you have adequate inventory on hand to meet customer demand. Reorder points indicate the inventory level at which you should initiate the replenishment process, minimizing the risk of stockouts. Safety stock acts as a buffer to safeguard against unexpected spikes in demand or supplier delays.

6. Adopt Just-in-Time (JIT) Inventory Management

Just-in-Time (JIT) inventory management aims to minimize inventory holding costs by receiving goods and materials just in time for production or order fulfillment. This approach helps reduce storage needs, carrying costs, and the risk of obsolescence. However, careful planning and coordination with suppliers are essential to ensure the smooth implementation of JIT principles.

7. Regularly Analyze and Adjust Inventory Policies

Regularly reviewing and adjusting your inventory policies is crucial to ensure ongoing optimization of your warehouse operations. Analyze key performance indicators (KPIs) such as inventory turnover, stock accuracy, and order fulfillment rates. Make data-driven decisions to fine-tune your inventory management strategies and adapt to changing market demands.

By following these steps and incorporating the expertise of HCO Innovations, you can streamline your inventory management processes and achieve significant cost reductions. Our team of professionals will work closely with you to assess your current operations, identify areas for improvement, and implement tailored solutions that align with your business goals.

Conclusion

Efficient inventory management is vital for maximizing warehouse productivity, minimizing costs, and delivering exceptional customer service. By streamlining your inventory management processes, you can enhance your operational efficiency, reduce carrying costs, and improve your overall bottom line. Partnering with HCO Innovations and implementing the suggested steps will enable you to optimize your warehouse operations, increase your company's competitiveness, and achieve sustainable growth.