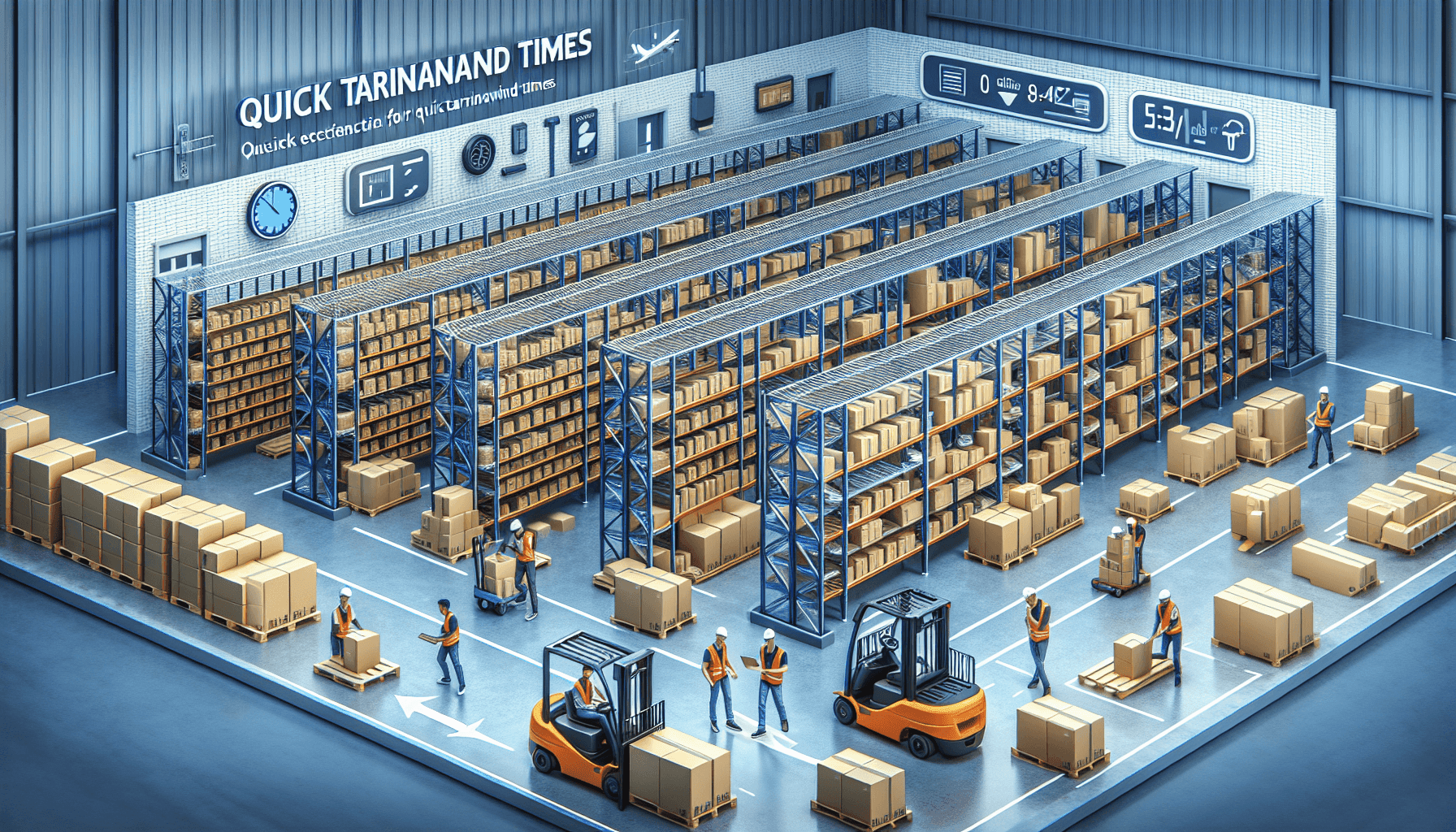

Creating an organized and efficient warehouse layout is crucial for any business that relies on timely order fulfillment and quick turnaround times. A well-planned warehouse layout can significantly improve productivity, reduce errors, and ultimately lead to higher customer satisfaction. In this article, we will explore some key considerations and best practices for planning your warehouse layout to achieve quick turnaround times.

Evaluate Your Current Layout

Before making any changes to your warehouse layout, it’s important to conduct a thorough evaluation of your current setup. This involves assessing factors such as the flow of materials, accessibility to different areas, and utilization of available space. By understanding the strengths and weaknesses of your current layout, you can identify areas for improvement and create a roadmap for optimizing your warehouse operations.

One effective way to evaluate your warehouse layout is to use a professional warehouse evaluation service. HCO Innovations offers a comprehensive warehouse layout evaluation that includes a detailed analysis of your current setup, expert recommendations for improvement, and a customized action plan. This service can provide valuable insights into how to optimize your warehouse layout for quick turnaround times.

Design for Efficient Flow

The flow of materials is a critical aspect of warehouse operations. Designing your layout to facilitate a smooth and efficient flow can help reduce the time taken to process orders and fulfill customer demands. Here are some key tips for designing a layout that maximizes flow:

- Group similar products together: Organize your warehouse based on product similarities to minimize travel time between picking locations.

- Establish designated pick and pack zones: Designate specific areas for picking and packing tasks to minimize bottlenecks and streamline operations.

- Implement a logical storage system: Arrange products based on demand, size, and frequency of access to optimize accessibility and minimize handling time.

- Consider automation: Explore the use of automation technologies such as conveyor belts and robotic picking systems to streamline material flow.

Optimize Space Utilization

Inefficiencies in space utilization can hinder your warehouse’s ability to process orders quickly. Maximizing the use of available space can help accommodate more inventory and improve overall efficiency. Here are some strategies to consider:

- Use vertical space: Install tall, sturdy racks and shelves to maximize storage capacity and make efficient use of vertical space.

- Maintain organized aisles: Keep walkways clear and organized to allow for easy movement of personnel and equipment within the warehouse.

- Implement a systematic inventory management system: By implementing a robust inventory management system, you can optimize stock levels and ensure quick access to the right products.

- Consider mezzanine floors: If you have high ceilings, consider installing mezzanine floors to create additional storage or working space.

Ensure Safety and Ergonomics

Creating a safe and ergonomic working environment is essential for the well-being of your warehouse staff and also plays a significant role in efficient order processing. Consider the following factors when planning your layout:

- Provide adequate lighting: Ensure proper lighting throughout the warehouse to enhance visibility and reduce the risk of accidents.

- Implement proper signage: Clearly mark different areas of the warehouse, including emergency exits, loading docks, and hazardous zones.

- Invest in ergonomic equipment: Provide ergonomic workstations, lifts, and tools to minimize strain and injuries associated with repetitive tasks.

- Regularly train staff: Conduct regular safety training sessions to keep your employees updated on best practices and safety protocols.

Continuously Monitor and Adapt

Efficient warehouse layout planning is an ongoing process. As your business evolves and customer demands change, it’s important to continuously monitor your operations and adapt your layout accordingly. Regularly review and analyze key performance indicators such as order processing times and error rates to identify areas for improvement.

HCO Innovations is a leader in warehouse optimization solutions, and their expertise can help businesses achieve quick turnaround times through effective layout planning. With their warehouse layout evaluation service, you can gain valuable insights and implement changes that will enhance safety, productivity, efficiency, and cost-effectiveness within your warehouse operations.

In conclusion, planning your warehouse layout for quick turnaround times requires careful consideration of factors such as evaluating your current layout, designing for efficient flow, optimizing space utilization, ensuring safety and ergonomics, and continuously monitoring and adapting. Incorporating these strategies and utilizing the expertise of HCO Innovations can help streamline your warehouse operations and deliver better results for your business.