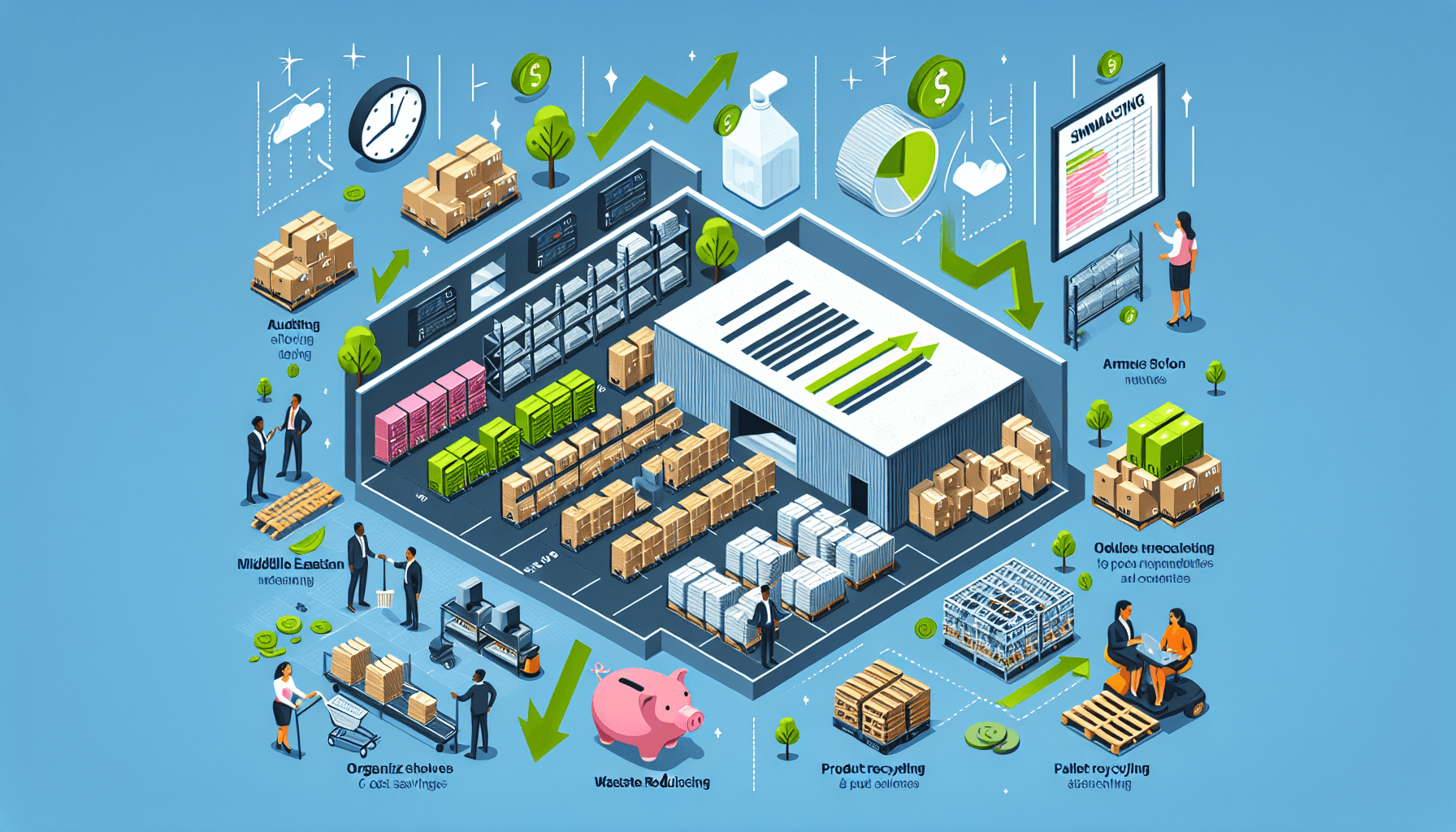

Warehouse waste can be a significant drain on both resources and profits. Inefficiencies in processes, lack of organization, and poor inventory management can all contribute to unnecessary waste within a warehouse. However, with the right strategies and solutions, businesses can effectively reduce warehouse waste and save money.

The Importance of Warehouse Optimization

Warehouse optimization is crucial for businesses looking to maximize their operational efficiency and reduce costs. By streamlining processes, improving productivity, and enhancing safety measures, companies can effectively minimize waste and improve their bottom line.

One of the key aspects of warehouse optimization is identifying areas of improvement. Conducting a thorough warehouse cost analysis can help businesses pinpoint inefficiencies and areas of waste. By analyzing key metrics such as storage utilization, picking accuracy, and order fulfillment time, companies can gain valuable insights into their warehouse operations and identify areas for improvement.

Warehouse cost analysis is a comprehensive evaluation of various factors impacting the cost of operations within a warehouse. It involves analyzing key performance indicators (KPIs) to identify areas of waste and identify opportunities for improvement.

Strategies to Reduce Warehouse Waste

Now that we understand the importance of warehouse optimization, let’s explore some effective strategies to reduce warehouse waste:

- Inventory Management: Implementing a robust inventory management system is essential for reducing waste. By accurately tracking inventory levels, avoiding overstocking or stockouts, and implementing effective replenishment strategies, businesses can minimize wastage due to obsolete stock or stockouts.

- Optimized Layout: Designing an optimized warehouse layout is crucial for improving efficiency. By strategically placing products, maintaining clear aisleways, and implementing efficient picking paths, businesses can minimize time wasted in searching for products and reduce errors due to disorganization.

- Efficient Material Handling: Implementing efficient material handling equipment and processes can significantly reduce waste. Utilizing technologies such as conveyors, forklifts, and pallet jacks can streamline movement within the warehouse, minimizing the risk of damage and improving productivity.

- Employee Training: Investing in regular training and development programs for warehouse staff is essential for reducing waste. Well-trained employees are more likely to follow best practices, operate equipment safely, and minimize errors, leading to improved overall efficiency in warehouse operations.

- Data Analysis: Leveraging data analytics can provide valuable insights into warehouse operations and help identify areas of waste. By analyzing data such as order volume, order accuracy, and picking time, businesses can identify trends, pinpoint bottlenecks, and make data-driven decisions to improve overall efficiency.

- Continuous Improvement: Implementing a culture of continuous improvement is vital for reducing warehouse waste. Encouraging employee suggestions, conducting regular process reviews, and identifying potential areas for optimization can help businesses stay ahead of the curve and continually improve warehouse operations.

The Benefits of Reducing Warehouse Waste

Reducing warehouse waste not only saves businesses money but also offers several other benefits:

- Cost Savings: By minimizing waste, businesses can reduce unnecessary expenses associated with excess inventory, inefficient processes, and errors, leading to significant cost savings.

- Improved Customer Satisfaction: Efficient warehouse operations translate to faster order processing and accurate deliveries, enhancing customer satisfaction and loyalty.

- Enhanced Safety: Implementing waste reduction strategies often involves improving safety measures within the warehouse. By minimizing hazards and promoting a safe working environment, businesses can reduce the risk of accidents and injuries.

- Increased Productivity: Streamlining processes and minimizing wastage leads to improved productivity. Employees can focus on value-added tasks rather than correcting errors or searching for misplaced items.

- Competitive Advantage: Businesses that have optimized warehouse operations and reduced waste are better positioned to compete in the market. They can offer faster order fulfillment, accurate inventory management, and lower prices, giving them a competitive edge.

Overall, reducing warehouse waste is essential for businesses looking to streamline operations, improve profitability, and stay ahead of the competition. By implementing the right strategies, leveraging technology, and fostering a culture of continuous improvement, companies can achieve significant cost savings and create a more efficient and profitable warehouse environment.