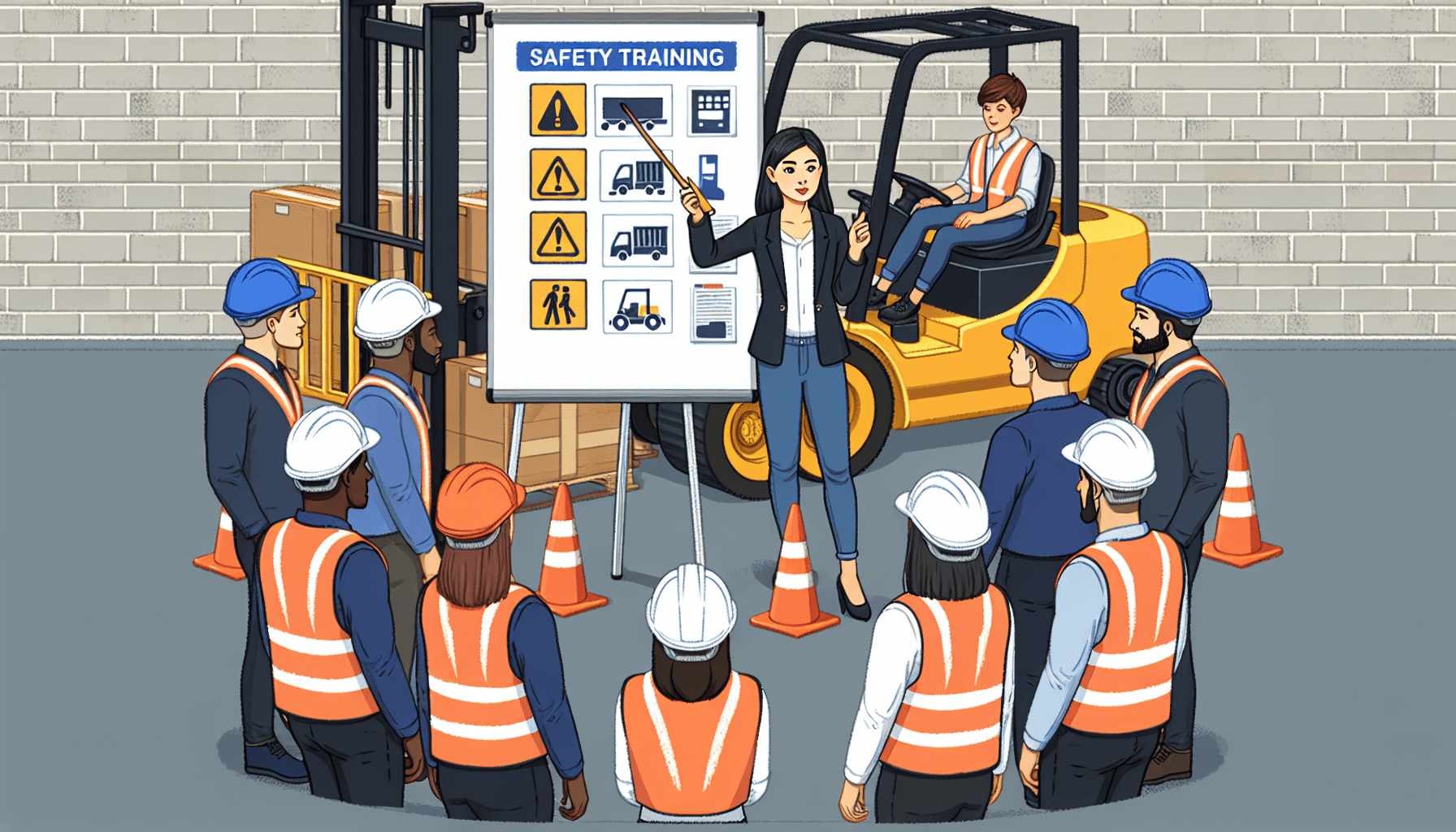

When it comes to working in a warehouse environment, safety should always be a top priority. One crucial aspect of warehouse safety is forklift operation. Forklifts are commonly used in warehouses to move heavy loads, but they can also pose significant risks if not operated correctly. That’s why it’s essential to have proper training programs in place to educate new employees on forklift safety.

The Importance of Forklift Safety Training

Forklift accidents can result in serious injuries, property damage, and even fatalities. By implementing a comprehensive forklift safety training program, warehouse managers can create a safe working environment and reduce the likelihood of accidents. Training new employees on forklift safety not only helps protect them from harm but also ensures the productivity and efficient functioning of warehouse operations.

Here are some essential steps to consider when training new employees on forklift safety:

1. Start with Classroom Training

Before new employees get hands-on experience with forklift operations, it’s crucial to begin with a comprehensive classroom training session. This training should cover the basics of forklift safety, including:

- Understanding the components and controls of a forklift

- Properly inspecting a forklift for any defects or damage

- The importance of wearing appropriate personal protective equipment (PPE)

- Safe operating procedures, including speed limits, load capacity, and stability

- Recognizing potential hazards in the warehouse environment

Classroom training provides a solid foundation of knowledge for new employees, ensuring they understand the essential safety protocols before operating a forklift.

2. Hands-On Training and Practice

Once new employees have completed the classroom training, it’s time for hands-on training and practice. This portion of the training allows employees to apply what they’ve learned in a controlled environment.

During the hands-on training, employees should be taught:

- How to start and stop the forklift

- Proper maneuvering techniques, including turning, reversing, and parking

- Safe loading and unloading procedures

- How to navigate ramps, narrow spaces, and other challenging areas

- Stacking and unstacking loads correctly

Training new employees on operating a forklift should be conducted by certified instructors or experienced forklift operators. It’s crucial to emphasize safety practices and correct any mistakes or improper techniques during this hands-on training.

3. Ongoing Evaluation and Refresher Training

Forklift safety training is not a one-time event. It’s important to perform regular evaluations to assess employees’ understanding and skills in forklift operation. Ongoing evaluation can help identify areas for improvement and provide targeted refresher training as needed.

Additionally, it’s important to stay up-to-date with any changes in forklift regulations or safety guidelines. This information should be incorporated into ongoing training sessions to ensure employees are aware of the latest best practices.

At HCO Innovations, we understand the importance of forklift safety and warehouse optimization. Our team of experts specializes in creating customized warehouse safety evaluation solutions to enhance the safety, productivity, and efficiency of warehouse operations. With our comprehensive approach, we can help improve forklift safety training programs and create a safer work environment.

If you’re looking to optimize your warehouse safety, consider booking a warehouse safety evaluation with HCO Innovations. Our experts will assess your current safety protocols and provide recommendations to enhance your warehouse’s safety standards.

Conclusion

Training new employees on forklift safety is crucial to prevent accidents, injuries, and damage in a warehouse environment. By providing comprehensive classroom training, hands-on practice, and ongoing evaluation, warehouse managers can ensure that their employees have the necessary skills and knowledge to operate forklifts safely. Remember, safety should always be a top priority, and investing in proper training can lead to long-term benefits for both employees and the overall efficiency of warehouse operations.