Warehouse safety is of utmost importance for any business operations that involve the storage and movement of goods. Not only does it ensure the well-being of workers, but it also contributes to the overall efficiency and productivity of the warehouse. Implementing a cost-effective warehouse safety program is crucial for businesses looking to enhance their safety measures while optimizing their operations.

The Importance of a Warehouse Safety Program

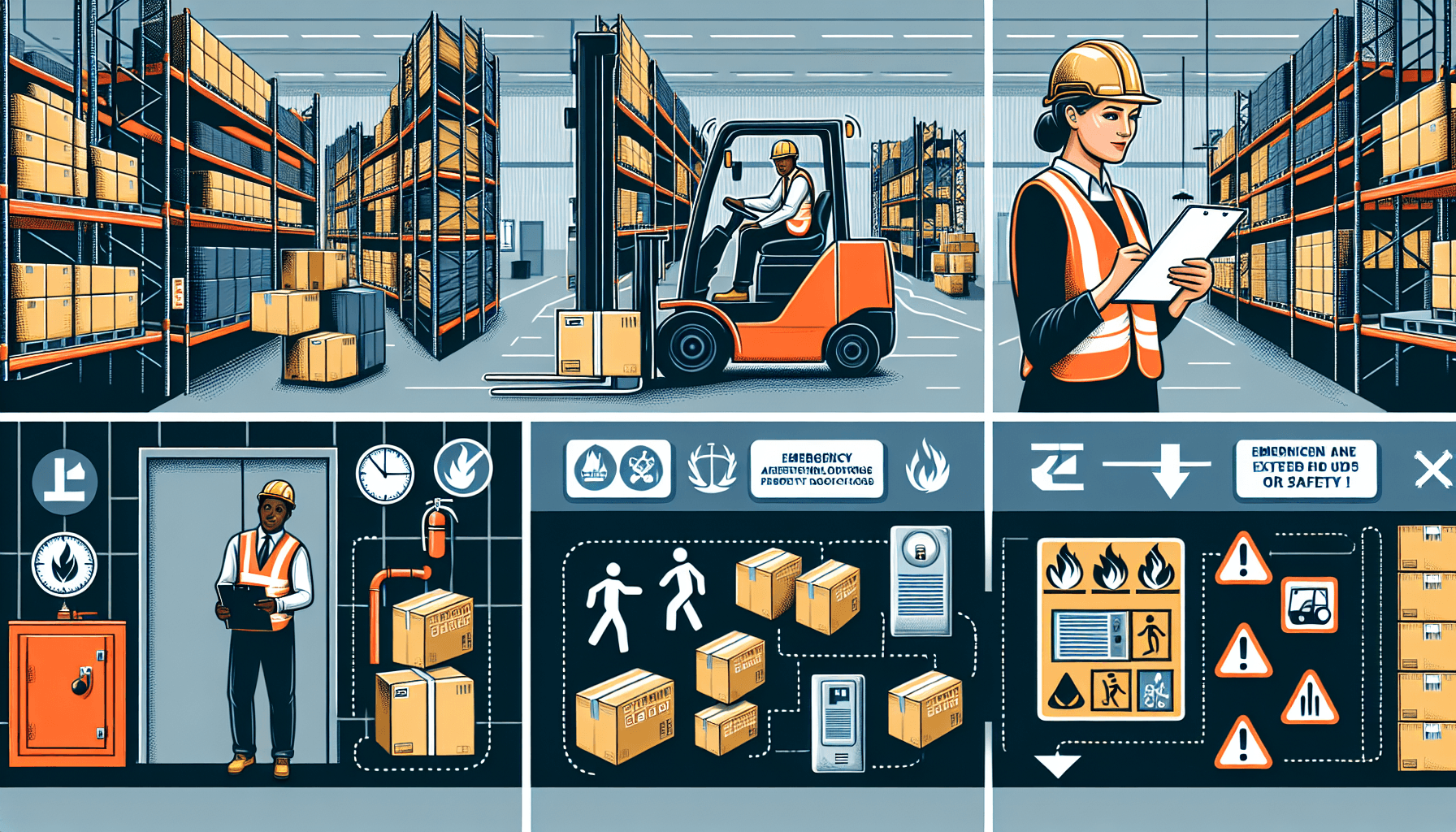

A warehouse safety program is a set of policies and procedures designed to prevent workplace accidents and injuries. It includes protocols for equipment operation, materials handling, emergency response, and employee training. By implementing a comprehensive safety program, businesses can create a safer working environment, reduce accidents and injuries, and minimize operational disruptions.

One of the key benefits of a warehouse safety program is the protection it provides for employees. By identifying and addressing potential hazards, businesses can significantly reduce the risk of workplace accidents and injuries. This not only improves employee morale but also reduces workers’ compensation costs and potential legal liabilities.

Beyond employee safety, a warehouse safety program also contributes to overall operational efficiency. By implementing safe work practices and protocols, businesses can minimize accidents and equipment breakdowns, leading to increased productivity and reduced downtime. Additionally, a well-designed safety program promotes organized and efficient material handling, which improves inventory management and order fulfillment processes.

Key Elements of a Cost-Effective Warehouse Safety Program

Implementing a cost-effective warehouse safety program involves addressing several key elements. Here are some essential components that businesses should consider:

- Management Commitment: The commitment of management is vital in creating a culture of safety within the organization. Management should actively support and promote the importance of safety, provide necessary resources, and lead by example.

- Employee Training: Properly trained employees are more likely to adhere to safety protocols and practices. Providing comprehensive training on equipment operation, handling hazardous materials, emergency response, and proper ergonomics is essential for preventing accidents and injuries.

- Regular Inspections and Audits: Conducting regular inspections and audits allows businesses to identify potential hazards and risks. This includes checking equipment, storage systems, and work areas for any signs of damage or deterioration. Regular inspections help identify and address safety issues proactively.

- Hazard Identification and Risk Assessment: Businesses should actively identify and assess potential hazards within the warehouse. This involves evaluating storage practices, material handling procedures, and identifying any potential sources of accidents. By having a clear understanding of the risks, appropriate safety measures can be implemented.

- Effective Communication: Clear and effective communication is crucial in ensuring that all employees are aware of safety procedures, protocols, and any updates or changes. Regular safety meetings, notices, and training sessions help reinforce safe practices and address any concerns or questions.

- Continuous Improvement: A cost-effective warehouse safety program should be dynamic and adaptable. Regularly reviewing and evaluating safety processes allows businesses to identify areas for improvement and implement corrective measures.

Implementing a cost-effective warehouse safety program requires careful planning, integration, and ongoing monitoring. It is essential to collaborate with experienced professionals who specialize in warehouse optimization solutions for a successful implementation. Companies like HCO Innovations offer comprehensive warehouse cost analysis and optimization services to help businesses create efficient and safe warehouse operations.

HCO Innovations is a leading provider of warehouse optimization solutions based in Raleigh, NC. With their expertise in enhancing safety, productivity, efficiency, and cost-effectiveness, HCO Innovations can assist businesses in implementing a cost-effective warehouse safety program.

In Conclusion

Implementing a cost-effective warehouse safety program is crucial for businesses looking to optimize their operations while ensuring the well-being of their employees. By focusing on key elements such as management commitment, employee training, regular inspections, hazard identification, effective communication, and continuous improvement, businesses can create a safe working environment that promotes productivity and efficiency. Collaboration with experienced professionals like HCO Innovations can provide valuable insights and assistance in implementing a successful warehouse safety program.