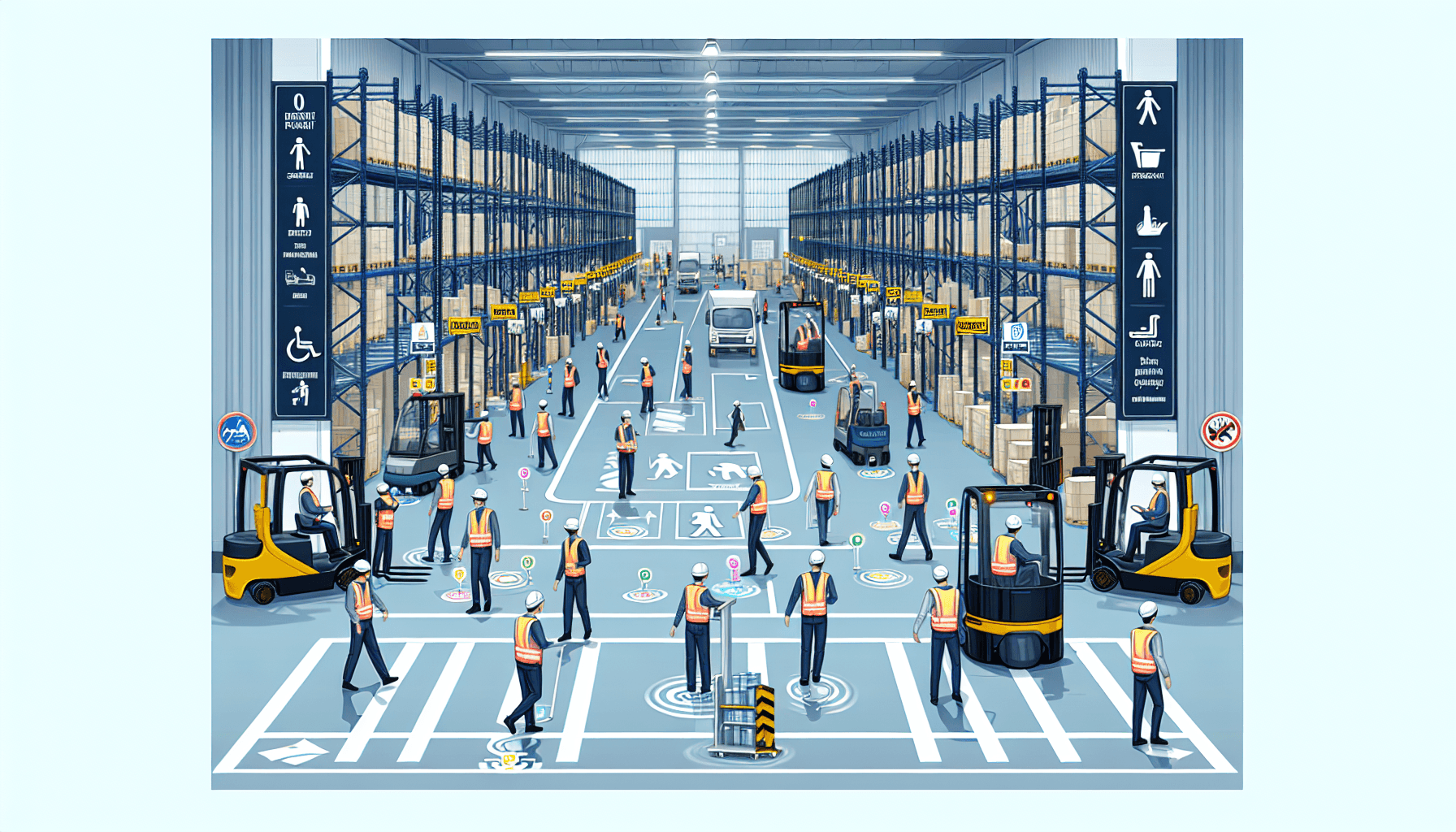

Warehouses are bustling hubs of activity, with forklifts, pallet jacks, and pedestrians constantly on the move. While these operations are essential for efficient warehouse management, they also pose significant safety risks. According to OSHA, almost 20% of all forklift accidents involve pedestrians. This alarming statistic highlights the need for implementing effective safety measures in warehouses to protect the well-being of employees and visitors.

The Importance of Pedestrian Safety in Warehouses

Pedestrian safety should be a top priority in any warehouse setting. It not only helps in preventing accidents and injuries but also contributes to improved productivity and employee morale. When workers feel safe and confident in their working environment, they can focus on their tasks more effectively, leading to higher levels of productivity.

Implementing a proactive pedestrian safety program is critical for warehouse management. One such solution is the utilization of a comprehensive forklift pedestrian detection system. By implementing a reliable and advanced system, warehouse managers can significantly reduce the risk of incidents and injuries.

The Advantages of a Forklift Pedestrian Detection System

A forklift pedestrian detection system is a cutting-edge technology that utilizes sensors, cameras, and advanced algorithms to detect the presence of pedestrians in the vicinity of forklifts. These systems provide real-time alerts to both forklift operators and pedestrians, warning of potential collisions and facilitating quick corrective actions.

Here are some key advantages of implementing a forklift pedestrian detection system in warehouses:

- Enhanced Safety: The primary benefit of a forklift pedestrian detection system is the improved safety it provides. By alerting both forklift operators and pedestrians of potential risks, the system helps prevent accidents and injuries.

- Reduced Incidents and Downtime: By minimizing the chances of collisions between forklifts and pedestrians, the system helps warehouse management reduce incidents and downtime caused by injuries. This leads to improved efficiency and productivity.

- Cost Savings: Implementing a forklift pedestrian detection system can result in long-term cost savings for the warehouse. By reducing accidents and injuries, the company can avoid expensive medical bills, legal fees, and workers’ compensation claims.

- Improved Compliance: Warehouse operations must comply with strict safety regulations and standards. By implementing a forklift pedestrian detection system, warehouses can demonstrate their commitment to safety compliance and reduce the risk of legal penalties.

- Enhanced Efficiency: By reducing the risk of accidents and injuries, a forklift pedestrian detection system allows for faster and smoother warehouse operations. Workers can move freely without the fear of collisions, resulting in improved overall efficiency.

Implementing a forklift pedestrian detection system is a wise investment for warehouse management. It not only protects the well-being of employees and visitors but also contributes to a safer and more productive work environment.

Choosing the Right Forklift Pedestrian Detection System

When selecting a forklift pedestrian detection system for your warehouse, it is crucial to consider certain factors to ensure you choose the right solution:

- Reliability: Look for a system that is highly reliable and accurate in detecting pedestrians. The system should provide timely and accurate alerts to prevent incidents.

- Easy Integration: Ensure that the detection system can be easily integrated into your existing warehouse infrastructure without causing disruption or additional costs.

- User-friendly Interface: The system should have a user-friendly interface that is easy for both forklift operators and pedestrians to understand and use.

- Adaptability: Choose a system that can adapt to different warehouse environments and operating conditions. It should be able to handle varying lighting conditions, obstacles, and other factors that may affect detection accuracy.

- Excellent Support and Maintenance: Select a vendor that provides comprehensive support and maintenance services for the pedestrian detection system. This ensures that the system remains in optimal condition and performs reliably over time.

By considering these factors and choosing the right forklift pedestrian detection system, warehouse managers can effectively enhance safety and mitigate the risk of incidents in their facilities.

In conclusion, prioritizing pedestrian safety in warehouses is crucial for both employee well-being and operational efficiency. Implementing a reliable forklift pedestrian detection system not only reduces the risk of accidents and injuries but also improves productivity and contributes to a positive work environment. Investing in the right system ensures long-term benefits in terms of safety, efficiency, and cost savings. To learn more about forklift pedestrian detection systems and how they can benefit your warehouse operations, visit HCO Innovations.