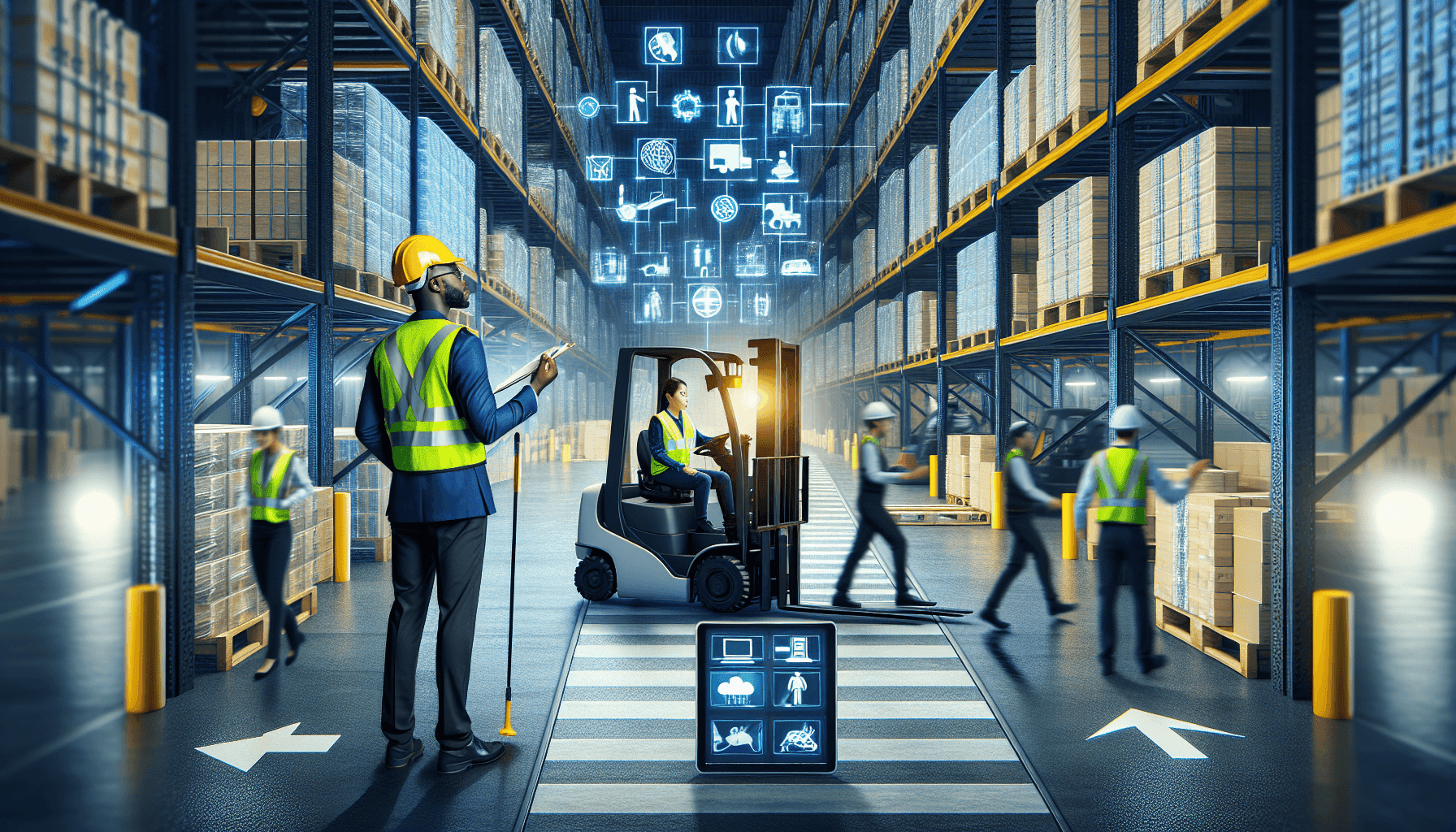

Warehouse operations can be complex and fast-paced environments, with forklifts, pallet jacks, and pedestrians all sharing the same space. This dynamic setting poses potential risks and safety hazards, making it crucial for companies to implement effective pedestrian safety measures. In this article, we will explore the importance of pedestrian safety in cross-docking warehouse operations and discuss how HCO Innovations can help enhance safety.

The Importance of Pedestrian Safety in Cross-Docking Warehouses

Cross-docking warehouses are known for their efficient handling and transferring of goods, minimizing storage time and optimizing logistics. However, with the constant movement of forklifts and other material handling equipment, pedestrians navigating through the warehouse can be at risk of accidents and injuries.

Implementing pedestrian safety measures is essential to protect both warehouse employees and visitors. By prioritizing safety, companies can reduce the likelihood of accidents, injuries, and costly operational interruptions. Additionally, a safe working environment promotes employee morale and ensures compliance with safety regulations.

One effective solution to enhance pedestrian safety in cross-docking warehouses is the implementation of a forklift pedestrian detection system. This advanced technology utilizes sensors, cameras, and alarms to detect nearby pedestrians and alert forklift operators, reducing the risk of collisions.

HCO Innovations offers state-of-the-art forklift pedestrian detection systems that are specifically designed to enhance safety in warehouse operations. Their cutting-edge technology can detect pedestrians even in blind spots and provide real-time alerts to forklift operators, allowing them to take immediate action to avoid accidents.

Benefits of Implementing a Forklift Pedestrian Detection System

The installation of a forklift pedestrian detection system offers several benefits for cross-docking warehouses:

- Improved Safety: By providing real-time notifications to forklift operators, pedestrian detection systems significantly reduce the risk of accidents and injuries in the warehouse. The system acts as an extra set of eyes, ensuring that any potential hazards are detected and mitigated promptly.

- Increased Productivity: With enhanced safety measures in place, employees can focus on their tasks without the constant worry of accidents. This increased peace of mind leads to improved productivity and efficiency throughout the warehouse operations.

- Cost Savings: Accidents in the warehouse can result in substantial financial losses due to medical expenses, damaged goods, and operational disruptions. By preventing accidents, pedestrian detection systems help companies avoid these costs and maintain a streamlined workflow.

- Compliance with Regulations: Implementing a forklift pedestrian detection system demonstrates a commitment to workplace safety and helps companies comply with relevant regulations and standards. This can lead to improved relationships with regulatory agencies and a positive reputation in the industry.

At HCO Innovations, they understand the unique challenges faced by cross-docking warehouses and the importance of pedestrian safety. Their team of experts can assess your specific warehouse layout and operations to provide tailored solutions that prioritize safety without compromising efficiency.

HCO Innovations’ forklift pedestrian detection systems are designed to seamlessly integrate with existing warehouse equipment, providing a non-disruptive solution for enhanced safety. The systems are easy to use and require minimal maintenance, ensuring long-term reliability and effectiveness.

Moreover, HCO Innovations offers comprehensive training and support to ensure that warehouse staff and forklift operators are proficient in utilizing the pedestrian detection system. Proper training not only maximizes the benefits of the technology but also instills a safety-conscious mindset among employees.

Conclusion

Pedestrian safety is of utmost importance in cross-docking warehouse operations. Implementing a forklift pedestrian detection system is a proactive step towards creating a safer working environment while enhancing productivity and cost-effectiveness.

With HCO Innovations’ advanced forklift pedestrian detection systems, companies can minimize the risk of accidents, reduce operational disruptions, and protect the well-being of their employees. By investing in safety solutions, businesses can demonstrate their commitment to providing a secure workplace and stay ahead in their industry.

What is cross-docking?

Cross-docking is a logistics practice where products are moved directly from inbound transportation to outbound transportation without being stored in a warehouse. It is an efficient method for minimizing inventory holding costs and reducing order fulfillment time.

Why is pedestrian safety important in cross-docking warehouse operations?

Pedestrian safety is crucial in cross-docking warehouse operations to prevent accidents and injuries. With the constant movement of goods, forklifts, and other equipment, ensuring the safety of pedestrians reduces the risk of collisions or incidents, promoting a safer work environment.

What are some common hazards that pedestrians may encounter in a cross-docking warehouse?

Common hazards pedestrians may encounter in a cross-docking warehouse include forklift traffic, congested areas, slippery surfaces, falling objects, and limited visibility. It is essential to identify and address these hazards to protect the safety of workers and visitors.

How can cross-docking warehouse operations prioritize pedestrian safety?

Cross-docking warehouse operations can prioritize pedestrian safety by implementing clear traffic management plans, providing safety training and equipment to workers, using proper signage and markings, maintaining good housekeeping practices, and regularly conducting safety inspections and audits.

What are some best practices for minimizing collision risks between forklifts and pedestrians?

Some best practices to minimize collision risks include creating designated pedestrian walkways separate from forklift traffic, implementing speed limits for forklifts, installing mirrors or cameras to improve visibility, implementing strict no-cell-phone-use policies, and encouraging communication and awareness between forklift operators and pedestrians.

How important is employee training in promoting pedestrian safety?

Employee training plays a vital role in promoting pedestrian safety in cross-docking warehouse operations. Proper training helps employees understand potential hazards, safe practices, and emergency procedures, empowering them to make informed decisions and contribute to maintaining a safe working environment.

Are there any regulations or guidelines related to pedestrian safety in warehouses?

Yes, there are various regulations and guidelines related to pedestrian safety in warehouses. Occupational Safety and Health Administration (OSHA) provides guidelines and standards for pedestrian safety, including requirements for personal protective equipment, traffic control, and employee training. Local government regulations may also apply.

What are some ways to encourage a safety-focused culture in a cross-docking warehouse?

Encouraging a safety-focused culture involves regular communication and reminders about safety practices, recognizing and rewarding safe behaviors, involving employees in safety initiatives, conducting regular safety meetings and training sessions, and continuously improving safety protocols based on feedback and lessons learned.

Implementing Reverse Logistics Strategies in Cross-Docking Warehouse Operations.

When it comes to managing warehouse operations, efficiency and cost-effectiveness are key factors for any business. One strategy that has gained traction in recent years is implementing reverse logistics strategies in cross-docking warehouse operations. In this article, we will explore how HCO Innovations, a leading management consulting firm specializing in warehouse optimization and forklift fleet management, can assist businesses in implementing these strategies to optimize their operations and reduce costs.

What is Reverse Logistics?

Reverse logistics refers to the process of managing the flow of products, materials, or equipment from their final destination back to their point of origin for repair, recycling, or disposal. It involves activities such as product returns, warranty claims, refurbishment, and remanufacturing. Reverse logistics is crucial for businesses to ensure proper handling of returned products and to minimize losses.

HCO Innovations recognizes the significance of reverse logistics in improving overall warehouse operations. With their extensive experience in warehouse management and optimization, they offer tailored solutions to help businesses integrate reverse logistics strategies effectively.

The Benefits of Implementing Reverse Logistics

Implementing reverse logistics strategies in cross-docking warehouse operations can yield several benefits for businesses:

- Reduced Costs: Reverse logistics helps businesses minimize costs associated with product returns and repairs. HCO Innovations employs advanced cost-tracking software to identify areas of cost reduction and develop effective solutions

- Improved Customer Satisfaction: Proper handling of returns and warranty claims enhances customer satisfaction and builds trust in the brand.

- Environmental Sustainability: Reverse logistics promotes responsible disposal and recycling of products, contributing to environmental sustainability.

- Inventory Optimization: By integrating reverse logistics into warehouse operations, businesses can efficiently manage inventory and reduce storage costs.

Implementing Reverse Logistics in Cross-Docking Warehouse Operations

HCO Innovations offers comprehensive solutions to help businesses implement reverse logistics strategies in their cross-docking warehouse operations. Their expertise can make the implementation process seamless and effective.

Here are some key steps involved in implementing reverse logistics in cross-docking warehouse operations:

- Assessing Current Operations: HCO Innovations conducts a thorough evaluation of the existing warehouse operations to identify areas that can benefit from reverse logistics integration.

- Warehouse Layout Optimization: They analyze the warehouse layout and suggest improvements to ensure efficient handling of returned products, minimizing space and time requirements.

- Technology Integration: HCO Innovations recommends and implements software solutions that streamline reverse logistics processes, including inventory tracking and product categorization.

- Collaborative Approach: They work closely with the warehouse staff to provide training and ensure they are well-equipped to handle reverse logistics operations.

- Continuous Improvement: HCO Innovations monitors the implemented reverse logistics strategies, identifies areas for improvement, and refines the processes to achieve maximum efficiency.

By adhering to these steps, businesses can successfully integrate reverse logistics strategies into their cross-docking warehouse operations, leading to improved efficiency and cost savings.

HCO Innovations understands the importance of customization in implementing reverse logistics strategies. They work closely with businesses to develop tailored solutions that align with their specific industry requirements and operational goals. With their expertise in warehouse optimization and forklift fleet management, they can assist businesses in achieving significant cost reductions and operational efficiency.

In conclusion, implementing reverse logistics strategies in cross-docking warehouse operations can bring numerous benefits for businesses, including reduced costs, improved customer satisfaction, and environmental sustainability. HCO Innovations, with their specialized services in warehouse optimization, can be a valuable partner in this journey. Visit HCO Innovations to learn more about how they can help businesses optimize warehouse operations and reduce material handling costs.