Efficient material flow is essential for maintaining accurate order fulfillment in any warehouse...

Streamline warehouse movement with expert material flow evaluation.

Material Flow Evaluation

People – Equipment – Workflow

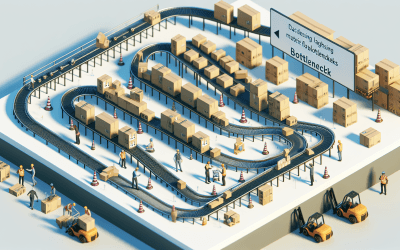

Material flow evaluation is a service designed to assess how materials move through your facility—reducing delays, improving efficiency, and eliminating bottlenecks. This service is ideal for warehouse managers, process engineers, and operations leaders looking to improve flow from receiving to shipping.

By examining physical layout, worker motion, and equipment use, we help you optimize your process and reduce unnecessary handling. Areas we typically assess include:

- Inbound receiving and putaway processes

- Product staging, picking, and packing flow

- Forklift and conveyor routing paths

- Workstation layout and material handling

- Shipping and outbound logistics zones

This evaluation improves throughput and builds a foundation for scalable, lean operations.

Warehouse Material Flow Optimization for Smoother Operations

Remove Bottlenecks

Improve Flow Efficiency

Build for Scalability

Learn More From Our Blog

How to Conduct a Material Flow Audit in Your Warehouse

Do you want to optimize the material flow in your warehouse? Are you looking for ways to improve...

How to Optimize Material Flow in High-Density Warehouses

Optimizing material flow is essential for the efficient functioning of high-density warehouses. In...

How to Address Bottlenecks in Material Flow

Are you experiencing bottlenecks in your warehouse operations? Do you find that your material flow...

How to Design a Material Flow Strategy for E-Commerce

When it comes to running a successful e-commerce business, optimizing your warehouse operations is...

How to Optimize Material Flow in Shared Warehouses

Warehouse operations can be complex and challenging, especially when it comes to efficiently...

Why Choose HCO Innovations for Material Flow Evaluation?

At HCO Innovations, we bring a practical, data-backed approach to material flow evaluation. Our team doesn’t just look at diagrams—we walk the floor, observe your operations, and develop real-world strategies that fit your unique facility layout. We focus on helping your people, products, and equipment move better, faster, and smarter.

- In-depth analysis of workflows from receiving to shipping

- Hands-on evaluation of equipment usage and motion paths

- Tailored layout and process improvement recommendations

- Focus on eliminating delays and increasing throughput

- Support for lean initiatives and operational scaling

If you’re looking to increase productivity without a full facility redesign, our material flow evaluations are a smart first step.