A well-designed warehouse layout is crucial for the smooth functioning of any distribution center or fulfillment operation. It not only impacts the efficiency and productivity of the warehouse, but also its overall safety and cost-effectiveness. In today’s fast-paced business environment, it is essential for companies to adopt a continuous improvement approach to their warehouse layout to stay competitive and maximize their operational efficiency.

The Importance of Warehouse Layout Optimization

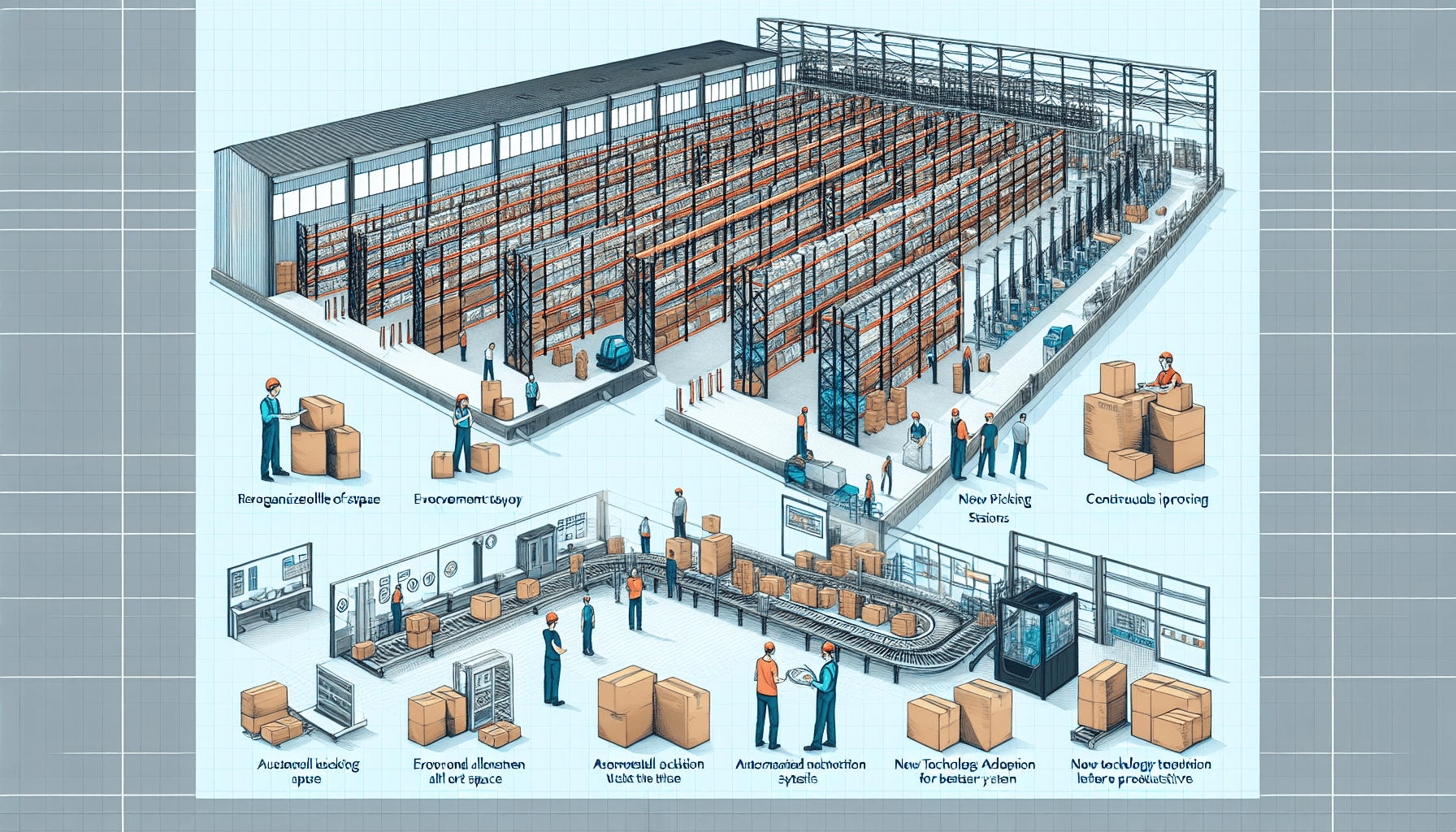

A warehouse layout refers to the physical arrangement of storage areas, aisles, racks, equipment, and workstations within a warehouse facility. An optimized warehouse layout streamlines the movement and storage of goods, reduces unnecessary material handling, minimizes travel distances, and maximizes space utilization.

By implementing an effective warehouse layout, businesses can experience numerous benefits, including:

- Improved Productivity: A well-designed warehouse layout ensures smooth flow of materials and minimizes bottlenecks, leading to increased efficiency and productivity. Workers can easily locate and retrieve items, reducing time wastage and improving order fulfillment speed.

- Enhanced Safety: An optimized layout ensures clear paths for workers and equipment, reducing the risk of accidents and injuries. It includes proper signage, designated walkways, and safety barriers to prevent collisions and falls.

- Cost Savings: A well-organized warehouse layout minimizes unnecessary movements and maximizes space utilization, leading to cost savings in terms of labor, storage space, and equipment. It helps companies avoid overstocking, stockouts, and reduces fulfillment errors.

- Flexibility and Scalability: A well-planned layout allows for easy reconfiguration and adaptation to changing business needs. It enables seamless expansion and integration of new processes and technologies.

To achieve a well-optimized warehouse layout, businesses can turn to warehouse optimization solutions providers, such as HCO Innovations. These companies specialize in evaluating and redesigning warehouse layouts to improve efficiency and productivity.

The Continuous Improvement Approach

The continuous improvement approach involves constantly evaluating and enhancing warehouse layout and processes to eliminate waste, reduce costs, and improve overall performance. It is a systematic and iterative process that includes the following steps:

- Assessment: Conduct a comprehensive evaluation of the existing warehouse layout, including the flow of materials, equipment utilization, storage systems, and overall efficiency. Identify areas of improvement and prioritize them based on their impact on the business.

- Data Analysis: Gather relevant data, such as product movement patterns, order volumes, and throughput rates. Analyze this data to identify opportunities for improvement and determine potential solutions.

- Design: Develop a new warehouse layout design that incorporates the identified improvements. Consider factors such as efficient space utilization, ergonomic workstations, optimized material flow, and safety measures.

- Implementation: Execute the planned changes within the warehouse, including reorganizing storage systems, moving equipment, and training employees on the new layout. Monitor the implementation process to ensure a smooth transition.

- Evaluation: Continuously monitor the performance of the new layout and collect data on key metrics, such as order accuracy, cycle time, and inventory accuracy. Compare these metrics against the pre-improvement benchmarks to assess the effectiveness of the changes.

- Continuous Improvement Cycle: Based on the evaluation results, identify further areas of improvement and repeat the process to achieve ongoing optimization.

The continuous improvement approach allows businesses to adapt to changing market conditions, customer demands, and operational requirements. It fosters a culture of innovation and encourages employees to actively contribute towards improving warehouse processes and layout.

Implementing Warehouse Optimization Solutions

To effectively implement a continuous improvement approach to warehouse layout optimization, businesses can rely on the expertise of warehouse optimization solutions providers like HCO Innovations. These companies offer a range of services, including:

- Warehouse Layout Evaluation: Conducting a detailed analysis of the current warehouse layout, including material flows, storage systems, and equipment utilization. This evaluation helps identify areas for improvement and provides actionable recommendations.

- Layout Redesign: Utilizing advanced software tools and expertise to design an optimized warehouse layout that promotes efficient material flow, reduces travel distances, and maximizes space utilization. The redesigned layout takes into account factors such as product characteristics, order volumes, and future growth projections.

- Equipment and Technology Integration: Recommending and implementing appropriate equipment and technologies to enhance warehouse operations, such as automated storage and retrieval systems (AS/RS), conveyor systems, and inventory management software.

- Training and Change Management: Providing training programs for warehouse personnel to adapt to the new layout, equipment, and processes. Change management strategies are employed to ensure smooth transition and acceptance of the changes.

- Performance Monitoring and Optimization: Continuously monitoring and measuring key performance indicators (KPIs) to track the efficiency and effectiveness of the new layout. Making ongoing adjustments and improvements based on the data collected to maintain optimal warehouse operations.

By partnering with warehouse optimization solutions providers like HCO Innovations, businesses can be confident in the continuous improvement of their warehouse layout, leading to increased productivity, safety, efficiency, and cost-effectiveness. Implementing an optimized layout not only provides immediate benefits but also sets the foundation for future growth and success in a rapidly evolving marketplace.