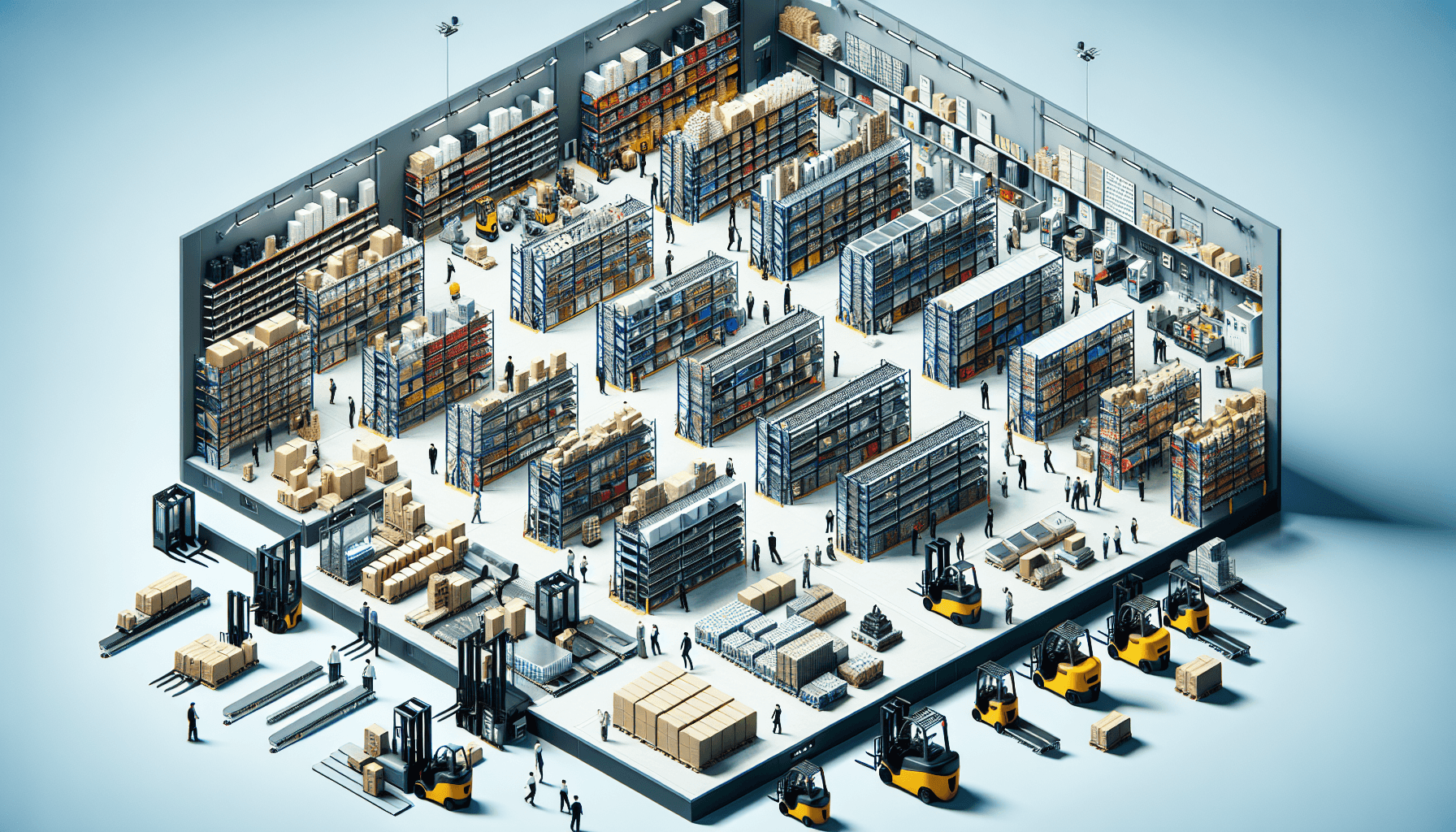

When it comes to optimizing warehouse operations, one key factor that plays a crucial role is the layout of the warehouse itself. The way items are organized and structured within a warehouse can have a significant impact on safety, productivity, efficiency, and cost-effectiveness. In recent years, there has been a shift towards decentralized warehouse layouts, and this approach is gaining popularity for several reasons.

Improved Efficiency

A decentralized warehouse layout is characterized by the distribution of different product categories and SKUs across multiple smaller storage areas or zones within the warehouse. This layout allows for easier access to products, reducing the time spent searching for and retrieving items. With a decentralized layout, items can be stored closer to the point of use, eliminating the need for long travel distances within the warehouse.

By reducing the time and effort required to locate and retrieve products, a decentralized warehouse layout can significantly improve efficiency. This improved efficiency translates into faster order processing times, increased productivity, and ultimately, improved customer satisfaction.

Enhanced Flexibility

A decentralized warehouse layout offers enhanced flexibility compared to a traditional centralized layout. In a decentralized layout, different storage areas or zones can be easily reconfigured or repurposed to accommodate changing inventory needs or seasonal demands. This flexibility allows warehouse managers to adapt to evolving business requirements without disrupting the overall warehouse operations.

Furthermore, a decentralized layout provides the opportunity for a more efficient use of space within the warehouse. Rather than relying on one large storage area, the warehouse can be divided into smaller zones, allowing for better utilization of available space. This flexibility in space allocation ensures that every inch of the warehouse is optimized for storage and that space is not wasted.

Improved Safety

Safety is always a top priority in warehouse operations. A decentralized warehouse layout can contribute to improved safety in several ways. Firstly, by reducing the amount of distance covered by warehouse staff to retrieve items, the risk of accidents and injuries from falls, collisions, or other hazards is minimized.

Additionally, a decentralized layout allows for better organization and segregation of hazardous materials or items that require special handling. This segregation helps prevent accidents and ensures that safety protocols are followed correctly.

Overall, a decentralized warehouse layout promotes a safer working environment for warehouse staff, resulting in a decrease in workplace incidents and injuries.

Cost-Effectiveness

Implementing a decentralized warehouse layout can also have cost-saving benefits. By reducing travel distances and optimizing space utilization, companies can see a reduction in labor costs and storage expenses. With more efficient access to products, the need for additional manpower to perform manual tasks is minimized, resulting in reduced labor costs.

Furthermore, a decentralized layout can lead to cost savings in terms of energy consumption. With smaller, more localized storage areas, there is less need for extensive lighting and climate control in the entire warehouse, resulting in lower utility costs.

Conclusion

A decentralized warehouse layout offers numerous benefits for businesses looking to optimize their warehouse operations. From improved efficiency and flexibility to enhanced safety and cost-effectiveness, this approach can have a positive impact on the overall performance of a warehouse.

If you are interested in evaluating your current warehouse layout or exploring options for a decentralized layout, HCO Innovations can help. Our warehouse optimization solutions are designed to enhance safety, productivity, efficiency, and cost-effectiveness within warehouse operations. Contact us today to learn more about our services and how we can assist you in achieving a decentralized warehouse layout.