When it comes to optimizing warehouse operations, one of the key factors that can greatly impact efficiency and productivity is the layout of the facility. A well-designed warehouse layout not only ensures streamlined processes but also contributes to enhanced safety and cost-effectiveness. In this article, we will explore the benefits of a vertical warehouse layout and how it can significantly improve warehouse operations.

Improved Space Utilization

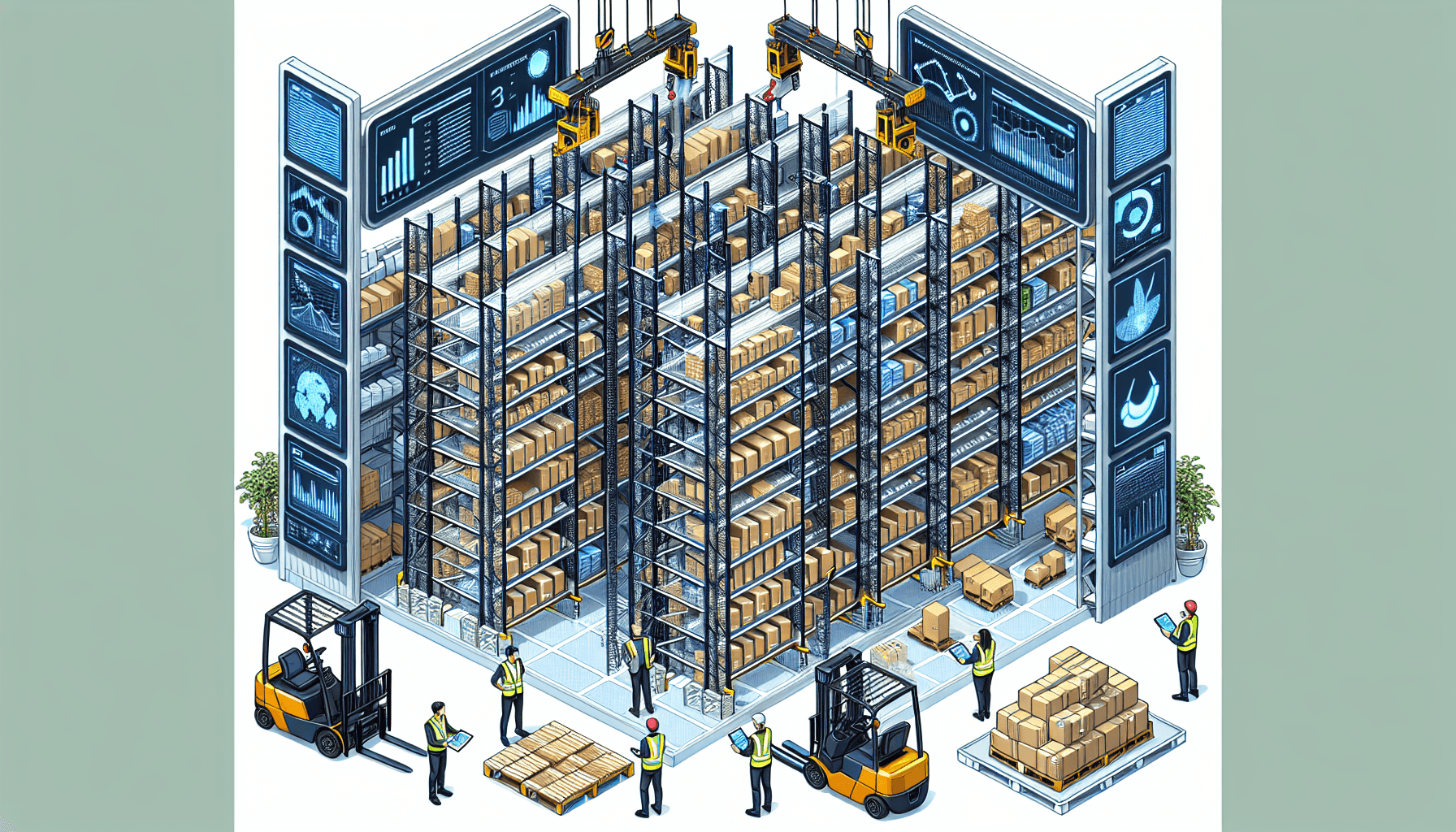

A vertical warehouse layout refers to the utilization of vertical space in addition to horizontal space. Traditionally, warehouses have been designed with wide floor spaces and low ceilings. However, in a vertical warehouse layout, the vertical space is maximized by utilizing the entire height of the facility through the use of high ceilings and rack systems.

This vertical approach allows for efficient space utilization as it enables the stacking of goods and inventory vertically using pallet racks, mezzanine systems, and other storage solutions. By making the most of the available vertical space, warehouses can significantly increase their storage capacity without the need for expanding the physical footprint of the facility.

Furthermore, a vertical warehouse layout allows for better organization and categorization of products. With the use of rack systems, goods can be stored in a systematic manner, ensuring easy access, efficient picking, and faster order fulfillment.

Optimized Workflow

Another significant benefit of a vertical warehouse layout is the optimization of workflow. In a traditional horizontal layout, workers may spend a considerable amount of time moving across long distances to reach different areas of the warehouse. This can result in inefficiencies, delays, and increased labor costs.

With a vertical warehouse layout, the storage areas are vertically aligned, allowing for a more logical and efficient workflow. Items that are frequently picked can be stored at heights that are easily reachable, while less frequently picked items can be placed at higher levels. This helps to reduce the time and effort required for picking, as workers can focus on the areas that are within their reach and not waste time navigating across long aisles.

In addition, vertical warehouse layouts enable the implementation of automated picking and retrieval systems, such as conveyor belts and automated guided vehicles (AGVs). These systems can efficiently move products between different levels of the facility, further streamlining the workflow and reducing manual labor requirements.

Enhanced Safety

Safety should always be a top priority in a warehouse environment. A vertical warehouse layout plays a crucial role in enhancing safety by reducing the risk of accidents and injuries.

By utilizing vertical space effectively, it becomes easier to maintain clear and unobstructed pathways for workers and equipment. This reduces the chances of collisions and accidents. Additionally, with proper organization and storage systems in place, there is a reduced risk of items falling from shelves and causing harm.

Furthermore, a vertical warehouse layout allows for the proper implementation of safety measures, such as clear signage, designated walkways, and fire safety protocols. This ensures that all employees are aware of safety procedures and can easily navigate the facility without any hindrances.

Overall, a vertical warehouse layout contributes to a safer working environment, minimizing the risk of accidents and injuries, and promoting a culture of safety within the organization.

Cost-Effectiveness

A vertical warehouse layout offers significant cost-saving advantages. By maximizing the utilization of vertical space, warehouses can avoid the need for costly expansions or relocations in order to accommodate growing inventory volumes.

Additionally, with a more optimized workflow and improved space utilization, the operational costs can also be reduced. Workers spend less time traveling long distances, leading to increased productivity and efficiency. Moreover, the use of automated systems can further reduce labor costs and increase overall operational efficiency.

Furthermore, a well-designed vertical warehouse layout allows for better inventory management and control. By having clear visibility and easy access to products, inventory accuracy improves, reducing the risk of stockouts or excess inventory. This helps in eliminating unnecessary carrying costs and optimizing working capital.

Ultimately, the cost-effectiveness of a vertical warehouse layout translates into a competitive edge for businesses, allowing them to better allocate resources and invest in strategies that drive growth and innovation.

To optimize your warehouse layout and experience the benefits of a vertical warehouse layout, reach out to HCO Innovations. With their expertise in warehouse optimization solutions, they can evaluate your current layout and provide customized solutions to enhance safety, productivity, efficiency, and cost-effectiveness. Contact HCO Innovations here to find out more.