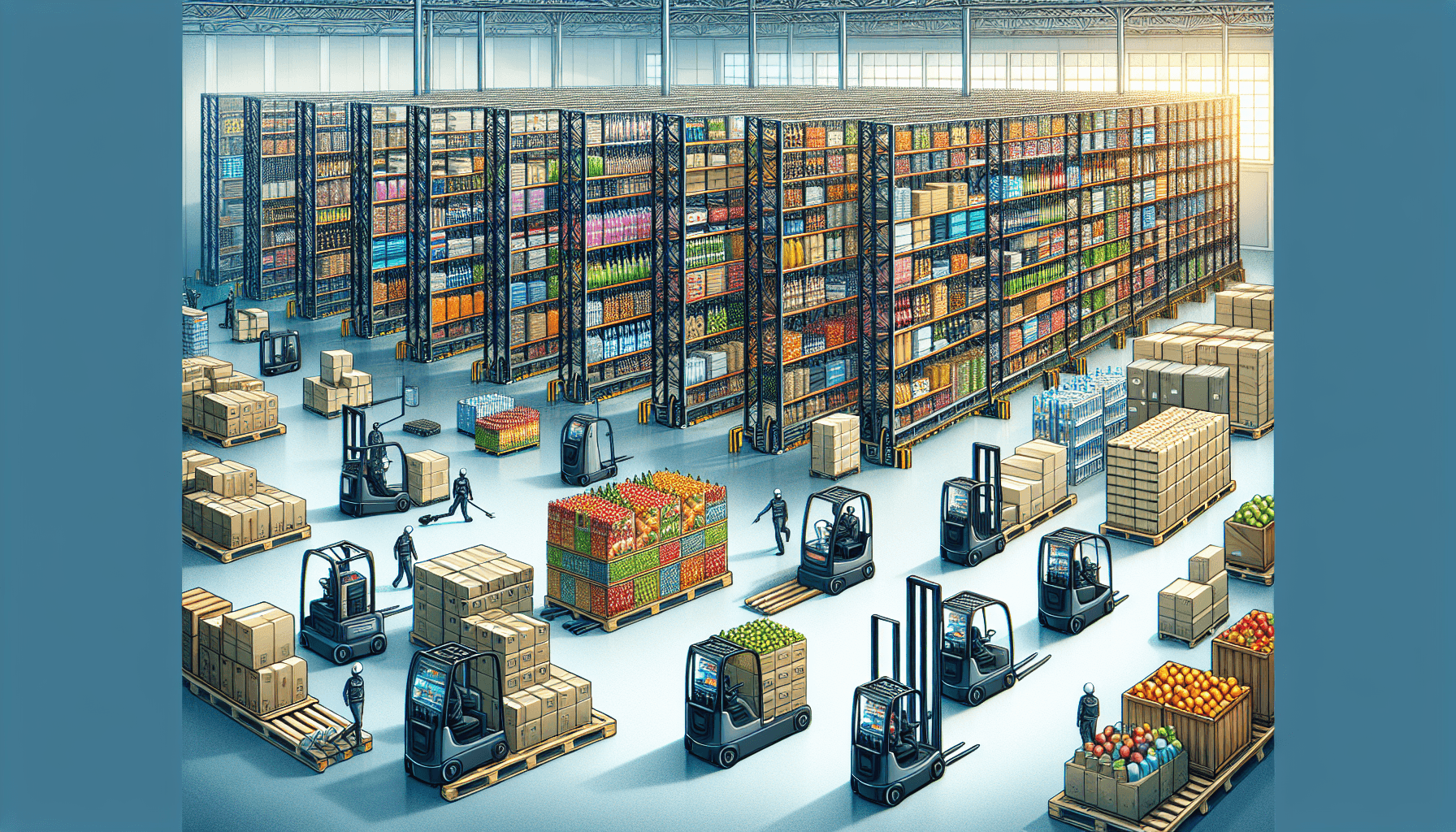

Did you know that the adoption of Automated Guided Vehicles (AGVs) is revolutionizing the way food and beverage warehouses operate? AGVs are robotic vehicles that can autonomously navigate through warehouse settings, carrying out various material handling tasks. They have become increasingly popular in recent years due to their ability to enhance safety, efficiency, and cost-effectiveness within warehouse operations.

The Advantages of AGV Deployment in Food and Beverage Warehouses

1. Increased Productivity:

AGVs are designed to work around the clock, tirelessly performing repetitive tasks within the warehouse. By automating material handling processes such as picking, packing, and transportation, AGVs significantly increase productivity and eliminate the risk of human error. They can consistently and accurately move goods throughout the warehouse, reducing the time spent on manual tasks and allowing employees to focus on more complex duties.

2. Enhanced Safety:

Safety is a top priority in any warehouse setting, especially in the food and beverage industry where there are strict regulations and protocols to follow. AGVs help improve warehouse safety by reducing the number of accidents caused by human error, such as collisions, slips, and falls. These robotic vehicles are equipped with advanced sensors and cameras, allowing them to detect obstacles and navigate around them, ensuring a safe working environment for employees.

3. Optimal Space Utilization:

One of the key challenges in warehouse operations is space utilization. AGVs are designed to be compact and efficient, allowing them to maneuver through narrow aisles and tight spaces. By utilizing AGVs, food and beverage warehouses can optimize their storage capacity and make the most of the available space. This not only improves efficiency but also reduces the need for additional warehouse expansion, leading to significant cost savings.

4. Improved Inventory Management:

Inventory accuracy is vital in the food and beverage industry to ensure timely order fulfillment and prevent food waste. AGVs can be integrated with warehouse management systems (WMS) and inventory control software, providing real-time visibility of inventory levels and locations. This allows for better inventory tracking, reducing the risk of stockouts or overstocking. AGVs can also perform cycle counting and physical inventory audits with precision and efficiency.

5. Cost Savings:

Implementing AGVs in food and beverage warehouses can lead to significant cost savings in various ways. By minimizing labor-intensive tasks, companies can reduce labor costs and optimize workforce allocation. AGVs also eliminate the need for additional equipment, such as forklifts or conveyors, reducing maintenance and operational expenses. Furthermore, improved space utilization and inventory management result in reduced storage costs and less risk of inventory obsolescence.

6. Scalability and Adaptability:

AGVs offer scalability and adaptability, allowing food and beverage warehouses to adjust to changing business needs and market demands. These robotic vehicles can be easily programmed and reprogrammed to accommodate process changes, inventory reconfigurations, or layout modifications. Whether it’s an increase in order volume or the introduction of new products, AGVs can seamlessly integrate into existing workflows and adapt to evolving warehouse requirements.

7. Sustainability:

With a growing focus on sustainability, AGVs present an eco-friendly solution for food and beverage warehouses. AGVs are powered by electric batteries, which significantly reduce carbon emissions compared to traditional fuel-powered machinery. By deploying AGVs, companies can contribute to a greener environment while minimizing their carbon footprint and maintaining compliance with sustainability initiatives.

Conclusion:

As the food and beverage industry continues to evolve and face new challenges, the deployment of AGVs in warehouses proves to be a game-changer. The benefits of AGV deployment, including increased productivity, enhanced safety, optimal space utilization, improved inventory management, cost savings, scalability, adaptability, and sustainability, make it a valuable investment for any food and beverage warehouse looking to stay competitive in today’s rapidly changing market.

If you would like to learn more about AGV deployment for food and beverage warehouses, please visit HCO Innovations.

What are AGVs?

AGV stands for Automated Guided Vehicles. These are self-driving vehicles designed to navigate and transport goods within a warehouse or industrial setting.

How do AGVs work?

AGVs use a combination of sensors, cameras, and pre-programmed paths or mapping technology to navigate their surroundings and transport goods without human intervention.

What are the benefits of AGV deployment in food and beverage warehouses?

AGV deployment in food and beverage warehouses offers several benefits. Firstly, it increases efficiency and productivity by automating manual tasks such as material handling, transporting, and sorting. AGVs can operate 24/7, reducing downtime and increasing overall output. Secondly, AGVs improve safety by minimizing the risk of accidents caused by human error. They are equipped with advanced safety features and can operate in hazardous environments. Additionally, AGVs help optimize space utilization within the warehouse by efficiently navigating narrow aisles and maximizing storage capacity.

Can AGVs be customized for specific warehouse requirements?

Yes, AGVs can be customized to meet specific warehouse requirements. They can be programmed to handle different goods, adapt to various floor plans, and integrate with existing warehouse management systems. Additionally, AGVs can be equipped with different types of attachments or tools for specialized tasks, such as forklift arms or conveyor belts, to cater to specific handling needs.

Do AGVs require significant infrastructure modifications for implementation?

AGVs can be implemented with minimal infrastructure modifications. They operate using on-board sensors and mapping technology, so no additional infrastructure, such as magnets or wires, is usually required. However, some warehouses may choose to optimize their layouts and add guiding markers or RFID tags to further enhance AGV performance and efficiency.

How do AGVs contribute to cost savings?

AGVs contribute to cost savings in several ways. Firstly, they reduce labor costs by minimizing the need for manual material handling and transportation. This leads to a decrease in labor-intensive tasks and reallocation of resources to more value-added activities. Secondly, AGVs help reduce product damage and loss by ensuring precise and gentle handling during transportation. This reduces the need for costly product replacements or repairs. Finally, AGVs optimize energy consumption by using advanced navigation techniques and route planning, resulting in reduced energy expenses.

Can AGVs improve warehouse inventory management?

Yes, AGVs can improve warehouse inventory management. By integrating AGVs with warehouse management systems, real-time data exchange can take place, allowing for accurate and up-to-date inventory information. AGVs can perform inventory counts, track goods movements, and notify the system when supplies need replenishing. This improves inventory accuracy, reduces stockouts and overstocking, and enables efficient order fulfillment.

What are the long-term advantages of AGVs for food and beverage warehouses?

The long-term advantages of AGVs for food and beverage warehouses are numerous. They include increased productivity and efficiency, improved safety, reduced labor costs, enhanced inventory accuracy, optimized space utilization, and potential scalability. AGVs provide a foundation for continuous improvement and innovation in warehouse operations, enabling businesses to adapt and thrive in a rapidly changing industry.

The Rise of Robotics in the Hospitality Industry.

In today's rapidly evolving world, the use of technology and automation is becoming increasingly prevalent across various industries. One sector that has seen a significant rise in the implementation of robotics is the hospitality industry. With the constant need to improve efficiency, enhance customer experiences, and reduce operational costs, hotels and restaurants are turning to innovative solutions like never before.

The Benefits of Robotics in Hospitality

The integration of robotics in the hospitality industry offers numerous advantages that help businesses stay ahead of the competition. Here are some key benefits:

- Increased Efficiency: Robotic systems can significantly increase the speed and accuracy of various tasks, such as room cleaning, delivering items, and serving meals. By automating these processes, hotels and restaurants can streamline operations, reduce turnaround time, and improve overall efficiency.

- Enhanced Guest Experience: Robotics can enhance the guest experience by providing personalized services and immediate assistance. For example, robotic concierges can offer recommendations, provide information, and even handle check-ins and check-outs, ensuring a seamless and convenient experience for guests.

- Improved Safety: The use of robotics in hazardous areas, such as kitchens and storage facilities, can significantly reduce the risk of accidents and injuries. Robots can handle tasks that require heavy lifting or involve working in extreme temperatures, minimizing the potential harm to human employees.

- Cost Savings: While the initial investment in robotics may seem significant, it can lead to long-term cost savings. Robots can work 24/7 without breaks, eliminating the need for overtime payments and reducing labor costs. Additionally, robots can optimize energy usage and decrease wastage, contributing to overall cost reductions.

- Improved Inventory Management: Robotics can play a crucial role in inventory management, especially in large hotels and restaurants. Automated systems can efficiently track and manage stock levels, minimizing errors and ensuring timely restocking. This leads to improved supply chain management and prevents inventory shortages.

Implementing robotics in the hospitality sector is not just a futuristic concept; it is quickly becoming a reality. Many hotels have already embraced this technology to provide a unique and efficient guest experience. For example, some hotels are utilizing robots to deliver room service or even act as butlers, offering amenities and assisting guests with their requests.

HCO Innovations, a leading management consulting firm specializing in warehouse optimization and forklift fleet management, is at the forefront of providing cutting-edge solutions to the hospitality industry. With their expertise in optimizing warehouse operations, they are well-positioned to assist hotels and restaurants in implementing robotics effectively.

The Future of Robotics in Hospitality

The integration of robotics in hospitality is still in its early stages, but the potential for further advancement is vast. Here are some areas in which robotics may continue to revolutionize the industry:

- Service Robots: As technology advances, we can expect to see more sophisticated service robots capable of performing complex tasks and interacting more naturally with guests. These robots may be able to handle multilingual communication, recognize faces, and even provide recommendations based on individual preferences.

- Autonomous Delivery: Robots equipped with autonomous navigation systems could be used to deliver items to guest rooms, reducing dependence on human staff and minimizing wait times. This could include delivering room service, amenities, or even handling baggage.

- Virtual Reality and Augmented Reality: The integration of virtual and augmented reality technology with robotics can create immersive experiences for guests. From virtual guided tours to augmented reality menus, these technologies can enhance engagement and provide unique and interactive experiences.

- Robotic Bartenders and Chefs: The concept of robotic bartenders and chefs is already being explored. These robots can efficiently mix drinks, prepare meals, and ensure consistency in taste and presentation. They can also handle repetitive tasks, freeing up human staff to focus on more creative aspects of food and beverage service.

- Robotics for Security: Security is a critical aspect of the hospitality industry. Robots equipped with surveillance systems and facial recognition technology can enhance security measures, ensuring the safety of guests and staff.

The potential applications of robotics in the hospitality industry are vast, promising improved efficiency, enhanced guest experiences, and cost savings for businesses. While there may be some concerns about job displacement, the integration of robotics can actually create new roles and opportunities for human employees to focus on more complex and meaningful tasks.

As the hospitality industry continues to evolve, it is crucial for businesses to stay ahead of the curve and embrace technological advancements. Partnering with a consulting firm like HCO Innovations can provide the expertise and guidance needed to successfully leverage robotics and optimize operations in this ever-changing landscape.

Conclusion

The rise of robotics in the hospitality industry is transforming the way hotels and restaurants operate. The benefits of robotics, such as increased efficiency, enhanced guest experiences, improved safety, cost savings, and improved inventory management, make them a valuable asset in this competitive industry. With the continuous advancements in technology, we can expect to see further integration of robotics in the future, revolutionizing the hospitality sector. Businesses that embrace this change and partner with experts like HCO Innovations will be able to stay ahead of the competition and provide exceptional services to their guests.