In today’s fast-paced and competitive business landscape, warehouse optimization has become a crucial aspect for companies to stay ahead. Warehouse operations play a pivotal role in ensuring a smooth supply chain, timely order fulfillment, and customer satisfaction. One of the key factors in optimizing warehouse operations is the efficient management of material handling equipment (MHE).

The Importance of Material Handling Equipment Management

Material handling equipment refers to the tools, vehicles, and machinery used in warehouses to move, store, and handle products and materials. Effective MHE management involves having the right equipment for the job, ensuring equipment uptime, and maximizing its utilization. Traditionally, manual labor has been the primary method of handling goods in warehouses. However, with advancements in technology, automated MHE solutions have gained significant popularity for their ability to revolutionize warehouse operations.

Automated MHE solutions, such as those offered by HCO Innovations, have transformed the way warehouses operate. These solutions streamline processes, reduce manual errors, enhance safety, maximize productivity, and drive cost savings.

The Benefits of Automated MHE

Automated MHE provides numerous benefits that contribute directly to cost savings and overall operational efficiency. Let’s take a closer look at some of these advantages:

1. Improved Productivity

Automated MHE systems can handle repetitive and physically demanding tasks with precision and speed. This allows warehouse staff to focus on value-added activities such as quality control, inventory management, and process improvement. By automating routine tasks, productivity is increased, and overall operational efficiency improves.

2. Reduced Labor Costs

Manual labor is costly, and allocating resources solely for material handling tasks can significantly impact a company’s bottom line. By implementing automated MHE solutions, companies can reduce the need for excessive labor, resulting in reduced labor costs. This allows companies to allocate their labor resources more effectively and allocate their workforce to other critical tasks within the warehouse.

3. Enhanced Safety

Warehouse operations involve numerous safety risks, particularly when it comes to manual material handling. Manual lifting and carrying heavy loads can result in injuries and accidents. Automated MHE systems, on the other hand, are designed with safety features that minimize the risk of accidents. These systems are equipped with sensors, alarms, and failsafe mechanisms, ensuring a safer working environment for warehouse employees.

4. Improved Accuracy and Efficiency

Automated MHE solutions can significantly reduce errors and improve accuracy in warehouse operations. By automating tasks such as picking, sorting, and inventory management, the chances of human error are reduced, leading to fewer mistakes and improved order accuracy. This not only enhances customer satisfaction but also minimizes costly order fulfillment errors.

5. Optimal Space Utilization

Space optimization is a critical aspect of warehouse operations. Automated MHE systems are designed to maximize the use of available space efficiently. These systems can operate in narrow aisles, utilize vertical space through high-stacking capabilities, and optimize storage arrangements. By utilizing space effectively, warehouses can reduce their overall footprint, leading to cost savings in terms of rental or construction expenses.

6. Real-time Data and Analytics

Most automated MHE systems are equipped with advanced technologies that provide real-time data and analytics. These systems can track inventory levels, monitor equipment performance, and generate valuable insights. Warehouse managers can use this data to make informed decisions, optimize processes, and identify areas for improvement. By analyzing data, companies can further enhance operational efficiency, reduce costs, and stay ahead of the competition.

The benefits of automated MHE solutions extend beyond just cost savings. They also contribute to improving customer service, reducing order cycle times, and increasing overall profitability. As technology continues to advance, the scalability and flexibility of automated MHE systems continue to improve, allowing companies to adapt to changing business needs seamlessly.

In conclusion, automated MHE solutions offer a wide range of benefits for warehouse operations, including cost savings, improved productivity, enhanced safety, increased accuracy, optimal space utilization, and access to real-time data and analytics. To learn more about how automated MHE solutions can benefit your warehouse operations, visit HCO Innovations.

What is Automated MHE?

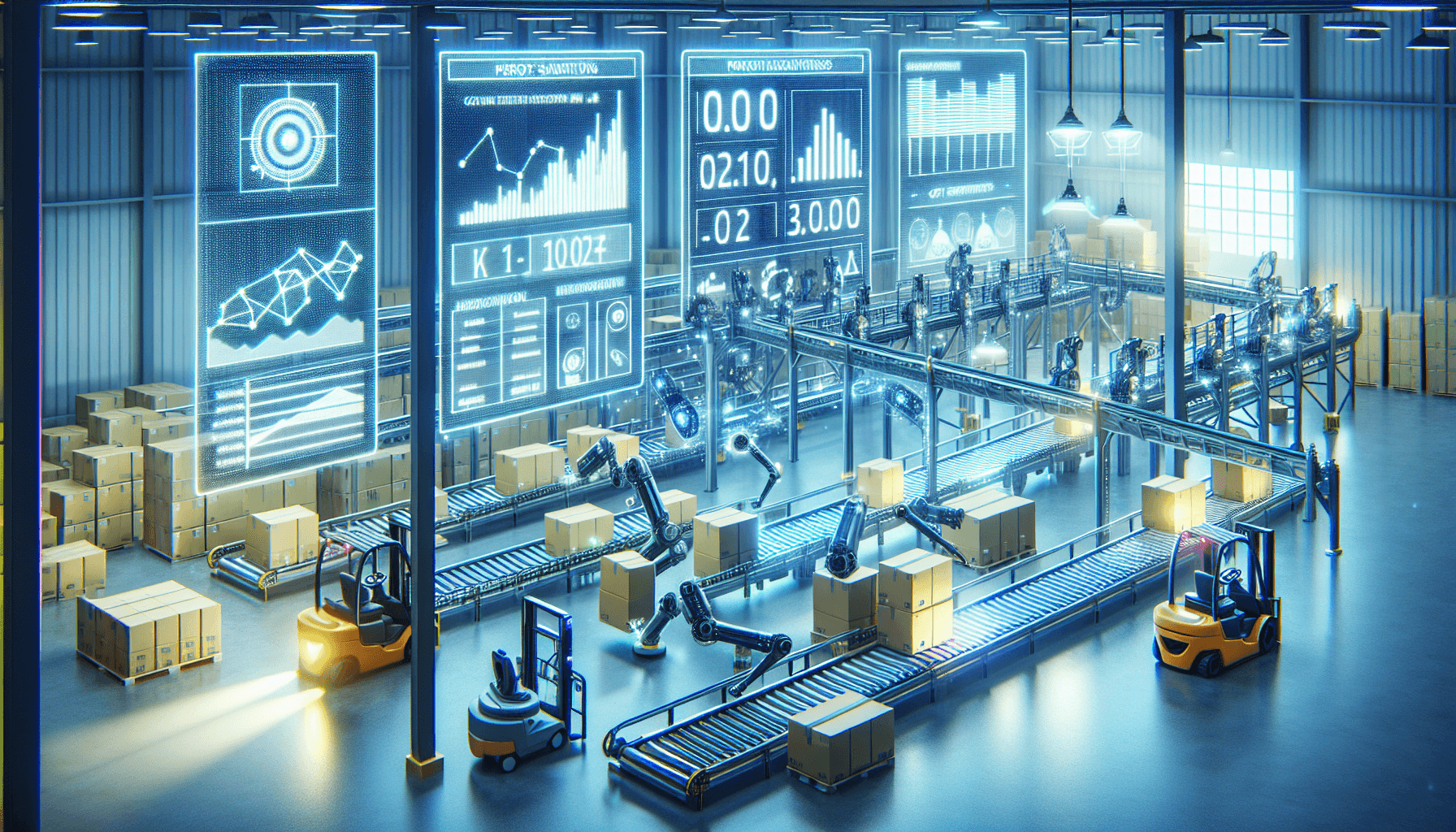

Automated MHE, or Material Handling Equipment, refers to the use of technology and machinery to automate various processes in material handling. It includes automated systems like conveyor belts, robotic arms, and automated guided vehicles (AGVs) that are designed to move, sort, stack, and store materials in a warehouse or distribution center.

How does Automated MHE help save costs?

Automated MHE can help save costs in several ways. Firstly, it reduces the need for manual labor, which can result in significant savings on labor costs. Additionally, automated systems can optimize efficiency, reduce errors, and minimize damage to products or equipment, leading to cost savings in terms of increased productivity and reduced waste. Moreover, automated MHE can enable better space utilization, allowing businesses to make the most of available storage space and potentially reducing the need for facility expansions.

Are there any upfront costs associated with implementing Automated MHE?

Yes, there are upfront costs associated with implementing Automated MHE. These costs typically include the purchase of automated equipment, installation, and integration with existing systems. The initial investment may vary depending on the scale and complexity of the automation project. However, it's important to consider these upfront costs in relation to the long-term cost savings and benefits that automated MHE can provide.

What are the potential long-term savings with Automated MHE?

The potential long-term savings with Automated MHE are significant. As mentioned earlier, automation can lead to reduced labor costs, increased productivity, and decreased errors or damages. These factors can result in improved operational efficiency and ultimately reduce operational expenses. Additionally, automated systems are often designed for durability and longevity, minimizing the need for frequent repairs or equipment replacements, which can result in further savings over time.

Is Automated MHE suitable for all types of businesses?

While Automated MHE offers various benefits, its suitability for businesses depends on several factors. The decision to implement automated systems should be based on factors such as the scale of operations, industry requirements, budget, and return on investment (ROI) considerations. It's important to evaluate specific business needs and conduct a thorough cost-benefit analysis to determine if Automated MHE is the right fit for a particular business.

Can Automated MHE be customized to fit specific business requirements?

Yes, Automated MHE can be customized to fit specific business requirements. Various automation solutions providers offer customization options to tailor the technology to the specific needs and processes of a business. This can include integrating automated systems with existing infrastructure, implementing specialized features, or accommodating unique space constraints. Consulting with automation experts can help businesses determine the level of customization possible for their specific requirements.

What are some potential challenges in implementing Automated MHE?

Implementing Automated MHE can come with certain challenges. Some common challenges include the need for proper planning and coordination during the implementation phase, potential disruptions to ongoing operations during installation or integration, and the requirement for specialized training for employees who will work with the automated systems. It's important to address these challenges proactively by working closely with automation providers and ensuring proper training and support for the transition.

Are there any risks associated with Automated MHE?

While there are risks associated with any technology implementation, proper planning and risk management can help mitigate these risks. Potential risks with Automated MHE can include system malfunctions, software glitches, and potential cybersecurity threats. However, reputable automation providers often provide ongoing support and maintenance services to address these risks. Investing in reliable equipment and implementing robust security measures can further minimize potential risks.

What industries can benefit from Automated MHE?

Automated MHE can benefit a wide range of industries. From manufacturing and e-commerce to healthcare and logistics, businesses that deal with material handling and storage can find value in adopting automated systems. The scalability and versatility of automated technology allow businesses in various sectors to optimize their operations, reduce costs, and improve overall efficiency.

The Future of Robotics in Warehouse Management

The future of warehouse management is rapidly evolving, and one of the key drivers of this transformation is the integration of robotics. With advancements in technology, robotics has become a game-changer in optimizing warehouse operations and driving efficiency. As a leading management consulting firm, HCO Innovations understands the importance of staying ahead of the curve when it comes to warehouse optimization and forklift fleet management.

Enhancing Efficiency with Robotics

Robotic technologies have made significant strides in recent years, offering a wide range of benefits when it comes to warehouse management. These advancements are enabling companies to streamline their operations, reduce costs, and enhance overall productivity. At HCO Innovations, we believe in leveraging these technologies to help our clients achieve optimal warehouse performance.

One of the key areas where robotics has made a significant impact is in material handling. Traditional warehouse operations often require manual labor for tasks such as loading and unloading, picking and packing, and inventory management. However, with the introduction of robotics, these processes can now be automated, eliminating the need for manual intervention.

Robotic solutions such as automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are proving to be game-changers in material handling. These robots are equipped with advanced sensors and algorithms that enable them to navigate through the warehouse environment, pick up and transport goods, and even collaborate with human workers. This not only reduces physical strain on human employees but also eliminates the risk of errors and improves overall efficiency.

Furthermore, robotics is revolutionizing the way warehouses are managed and optimized. With the help of robotics, warehouses can be equipped with smart sensors and connected devices that gather real-time data on various parameters such as inventory levels, product location, and equipment maintenance. This data can then be analyzed using advanced analytics and artificial intelligence algorithms to make data-driven decisions.

By leveraging this data, warehouse managers can optimize layout and storage, make informed predictions about demand and supply, and improve overall workflow. This, in turn, leads to reduced inventory holding costs, improved order fulfillment rates, and increased customer satisfaction.

At HCO Innovations, we understand the potential of robotics in warehouse management. That's why we offer comprehensive services to help our clients integrate robotics into their operations seamlessly. Our team of experts works closely with clients to evaluate their warehouse layout, design customized robotics solutions, and ensure smooth implementation.

The Benefits of Robotics in Warehouse Management

Integrating robotics into warehouse management offers a multitude of benefits across different industries. Here are some key advantages:

- Improved Efficiency: Robots can perform repetitive and strenuous tasks with precision, speed, and consistency, resulting in higher throughput and reduced labor costs.

- Enhanced Safety: By automating hazardous tasks, robots reduce the risk of workplace accidents and create a safer environment for employees.

- Increased Accuracy: Robotics technologies, coupled with advanced sensors and computer vision, ensure accurate and error-free operations, reducing the likelihood of inventory discrepancies and order fulfillment errors.

- Optimized Space Utilization: Robots can navigate through narrow aisles and utilize vertical spaces efficiently, enabling warehouses to maximize storage capacity.

- Real-Time Insights: Connected robotic systems generate real-time data, providing warehouse managers with valuable insights for continuous process improvement and decision-making.

These benefits highlight the potential for increased operational efficiency, cost savings, and improved customer satisfaction through the implementation of robotics in warehouse management.

The Role of HCO Innovations in Robotics Integration

As a leading management consulting firm specializing in warehouse optimization and forklift fleet management, HCO Innovations is at the forefront of integrating robotics into warehouse operations. Our extensive experience in this field allows us to understand the unique requirements of each client and design tailored solutions that deliver exceptional results.

When it comes to integrating robotics, we follow a collaborative approach. Our team works closely with clients to evaluate their current operations, identify areas for improvement, and design customized robotics solutions. We leverage advanced cost-tracking software and employ a "boots on the ground" approach to ensure seamless implementation and optimization.

Our services span across various aspects of robotics integration, including:

- Warehouse layout evaluation and optimization

- Safety assessments and risk management

- Customized robotics solutions design and implementation

- Turnkey maintenance and support

By partnering with HCO Innovations, companies in industries such as distribution, manufacturing, and food processing can achieve significant cost reductions, optimize warehouse operations, and streamline material handling processes. Our tailored solutions consistently deliver exceptional return on investment, making us a trusted partner for warehouse optimization.

In conclusion, the future of warehouse management lies in robotics integration. From enhancing efficiency and accuracy to optimizing space utilization and providing real-time insights, robotics offers a multitude of benefits. With HCO Innovations as a partner, companies can leverage these technologies to achieve operational excellence and gain a competitive edge in a rapidly evolving market.

Want to learn more about how HCO Innovations can help your business optimize warehouse operations and reduce material handling costs? Visit our website for more information.