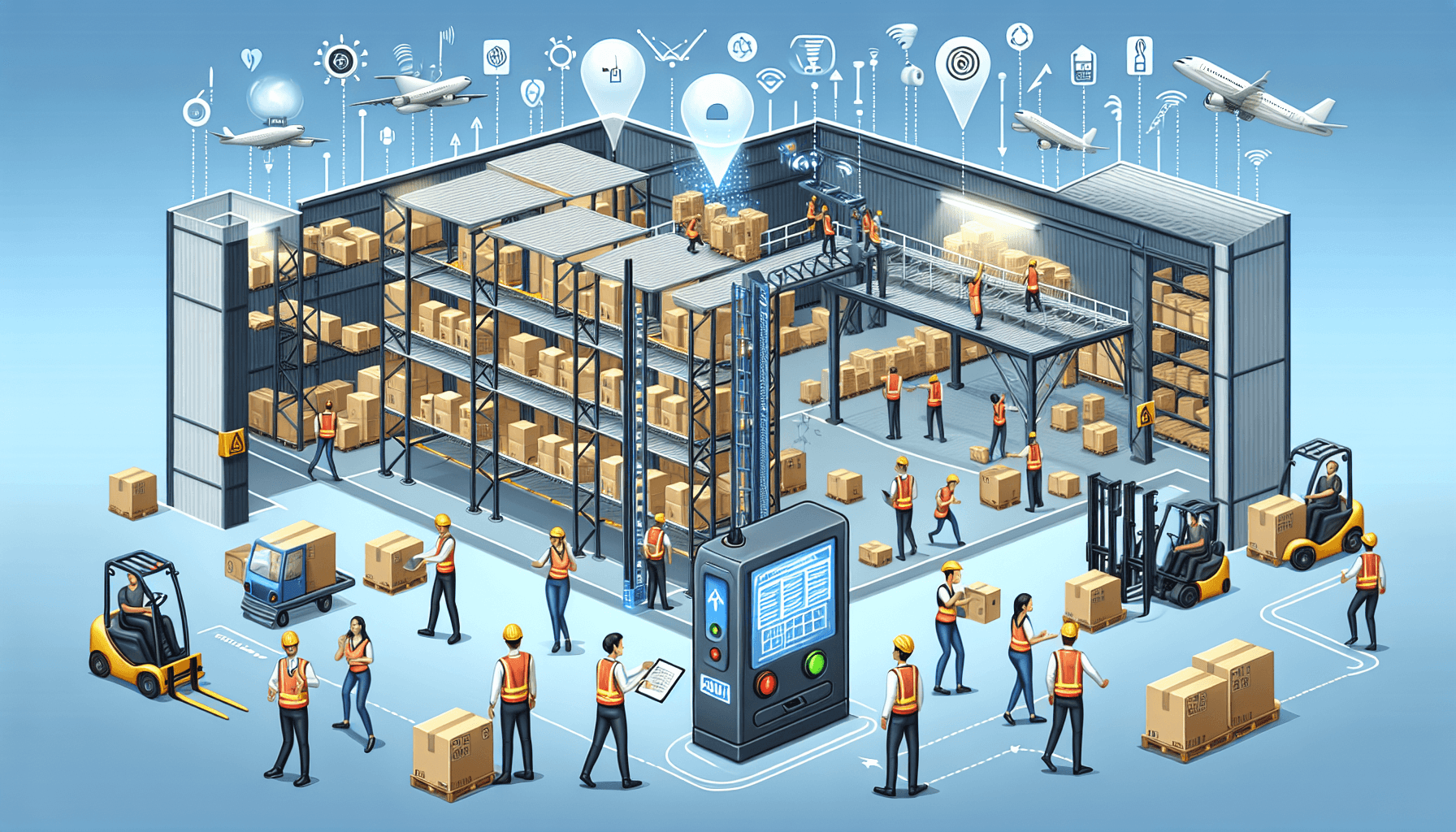

Warehouses are busy and dynamic environments where safety is of utmost importance. With the increasing demand for efficient operations and the need to ensure the well-being of workers, warehouse managers are constantly looking for ways to enhance safety measures. One solution that has gained traction in recent years is the implementation of automated safety systems.

The Power of Automation

Automated safety systems utilize advanced technologies and intelligent algorithms to monitor and control safety processes within the warehouse. These systems can encompass a range of features, including real-time monitoring, hazard detection, emergency response mechanisms, and more. By integrating automation into their safety protocols, warehouses can significantly improve the overall safety and well-being of their workforce.

One of the key benefits of automated safety systems is the ability to detect and respond to potential hazards in real-time. Through the use of sensors and smart algorithms, these systems can identify risks such as unauthorized access, collisions, or equipment malfunctions. Once a hazard is detected, the system can automatically trigger alarms, notifications, or even take corrective actions to prevent accidents.

This proactive approach to safety minimizes the reliance on human intervention and reduces the chances of accidents or injuries. It also allows for quicker response times, ensuring that any potential hazards are addressed promptly and effectively.

Enhancing Safety Measures

Automated safety systems can complement existing safety measures within the warehouse, maximizing the effectiveness of safety protocols. These systems can seamlessly integrate with other warehouse systems, such as inventory management or transportation systems, to provide a comprehensive safety solution.

For example, an automated safety system can be integrated with a warehouse management system to control access to restricted areas. By using identification badges or biometric authentication, the system can prevent unauthorized personnel from accessing hazardous areas, reducing the risk of accidents.

Furthermore, automated safety systems can also play a crucial role in incident reporting and analysis. By collecting and analyzing data from various sources, such as sensors or CCTV cameras, these systems can provide valuable insights into safety incidents. This information can be used to identify patterns, assess risks, and implement preventive measures.

The Benefits of Automated Safety Systems

Implementing automated safety systems in warehouses can result in several tangible benefits. Here are some of the key advantages:

- Improved Safety: By detecting and responding to potential hazards in real-time, automated safety systems minimize the risk of accidents and injuries.

- Increased Productivity: When workers feel safe and secure in their environment, they are more likely to be productive and efficient.

- Cost Savings: By preventing accidents or damage to equipment, automated safety systems can save warehouses significant costs associated with downtime and repairs.

- Regulatory Compliance: Automated safety systems can help warehouses comply with safety regulations and standards, ensuring a safe work environment for all.

- Enhanced Reputation: Demonstrating a commitment to safety can improve public perception and enhance the reputation of the warehouse.

In conclusion, automated safety systems offer a range of benefits for warehouses looking to improve safety measures and enhance overall operations. By leveraging advanced technologies and intelligent algorithms, these systems can proactively detect and respond to potential hazards, minimize the reliance on human intervention, and provide valuable insights for incident reporting and analysis. Implementing automated safety systems not only prioritizes the well-being of workers but also contributes to the efficiency, cost-effectiveness, and regulatory compliance within warehouses.

If you are interested in implementing an automated safety system in your warehouse, contact HCO Innovations to learn more about their warehouse optimization solutions and how they can improve safety, productivity, and efficiency in your operations.