Warehouses are dynamic environments with numerous moving parts, where safety and efficiency are of paramount importance. One crucial aspect of warehouse operations is the safety of workers and pedestrians who navigate through the facility. Implementing clearly marked walkways in warehouses can have significant benefits for both safety and productivity.

Enhanced Safety

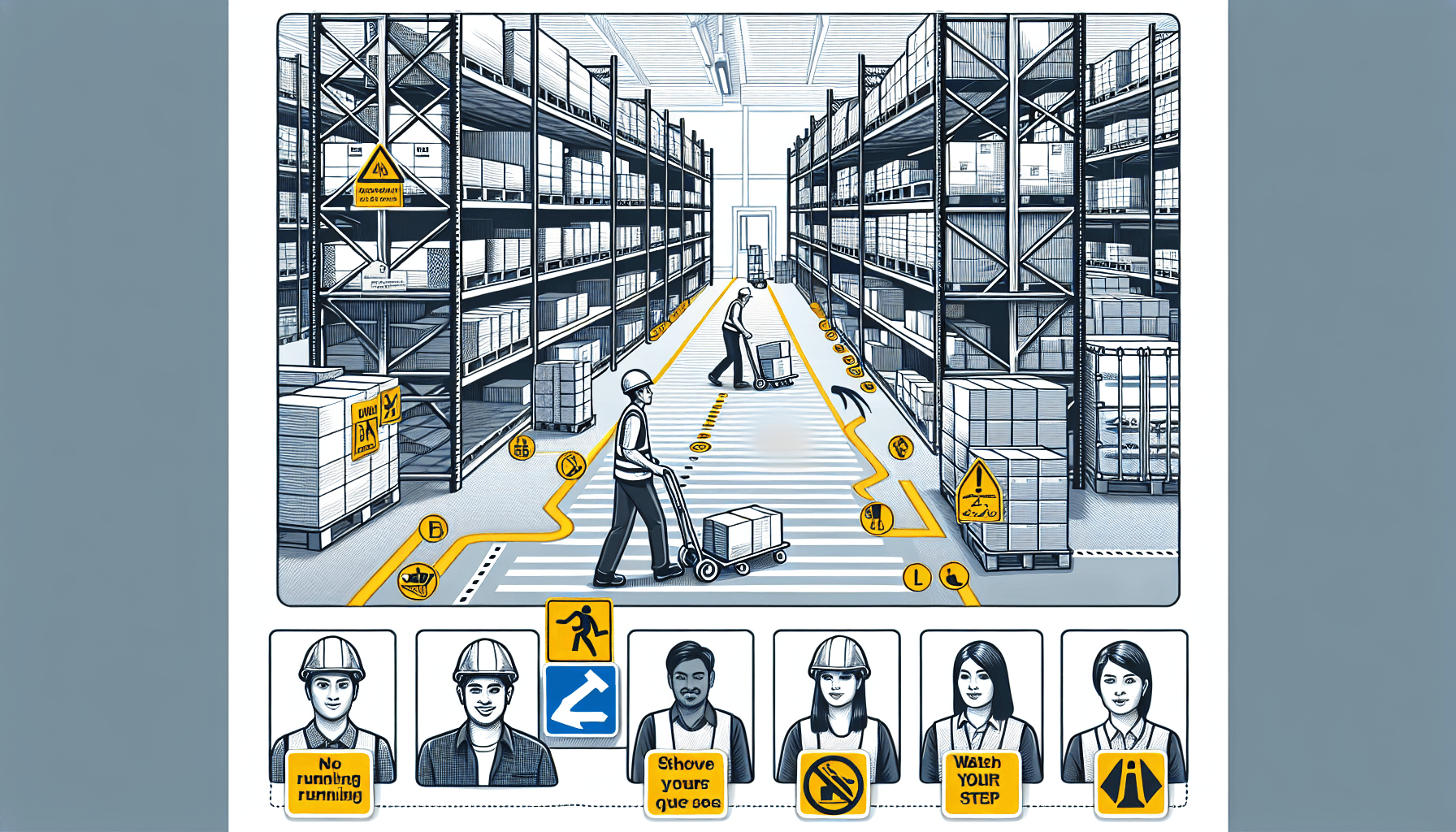

Clear and well-defined walkways play a vital role in ensuring the safety of workers in a warehouse setting. By clearly marking pedestrian pathways, employees have a designated route to follow, preventing them from straying into areas where forklifts or other moving machinery may be operating.

Accidents involving forklifts and pedestrians can have severe consequences, including injuries, property damage, and even fatalities. By using clear floor markings and signage to guide pedestrians, the likelihood of collisions and accidents can be greatly reduced.

Furthermore, clearly marked walkways help create a safety-conscious culture in the warehouse. When workers see and understand the importance of following designated paths, they are more likely to adhere to safety protocols and remain vigilant while navigating the facility.

Improved Workflow and Efficiency

In addition to enhancing safety, clearly marking walkways in a warehouse can also have a positive impact on workflow and overall efficiency of operations.

When employees have designated pathways to follow, it streamlines their movement throughout the warehouse. This reduces the chances of bottlenecks or congestion in high-traffic areas, allowing for smoother operations and increased productivity.

Clear walkways also enable workers to efficiently locate and access the items they need, improving their workflow and reducing the time spent searching for products. This helps to optimize picking and packing processes, which in turn leads to faster order fulfillment and improved customer satisfaction.

Another advantage of clearly marked walkways is the ability to easily identify and rectify any potential obstacles or hazards in the warehouse. If a walkway is blocked or an obstruction is identified, it can be quickly addressed, ensuring the smooth flow of operations and minimizing downtimes.

Compliance with Regulations

Implementing clearly marked walkways in warehouses not only promotes safety but also helps organizations stay in compliance with relevant regulations and industry standards.

Various regulatory bodies, such as the Occupational Safety and Health Administration (OSHA), have guidelines and requirements in place regarding warehouse safety. These regulations often include provisions for clearly marked aisles, pathways, and pedestrian walkways.

By adhering to these regulations and implementing proper floor markings, organizations can create a safer work environment and minimize the risk of penalties or fines for non-compliance.

HCO Innovations, a leader in warehouse optimization solutions, understands the importance of clearly marked walkways in enhancing safety and efficiency within warehouse operations. As a provider of innovative solutions, HCO Innovations offers cutting-edge technologies such as their Forklift Pedestrian Detection System.

HCO’s Forklift Pedestrian Detection System combines advanced sensors and real-time alerts to help prevent accidents and ensure the safety of pedestrians in warehouses. By integrating this system with the well-defined walkways and floor markings, organizations can further enhance safety measures and create a secure working environment.

In conclusion, clearly marked walkways in warehouses provide a range of benefits, from enhancing safety to improving workflow and complying with regulations. By implementing these measures and utilizing advanced technologies, such as the Forklift Pedestrian Detection System offered by HCO Innovations, organizations can create a productive, efficient, and secure warehouse environment.