Warehouse operations play a vital role in the success of any business. Efficient and optimized warehouse management can significantly impact a company’s bottom line. That’s where HCO Innovations comes in. As a leading provider of warehouse optimization solutions based in Raleigh, NC, they specialize in enhancing safety, productivity, efficiency, and cost-effectiveness within warehouse operations.

The Need for Collaborative Warehouse Networks

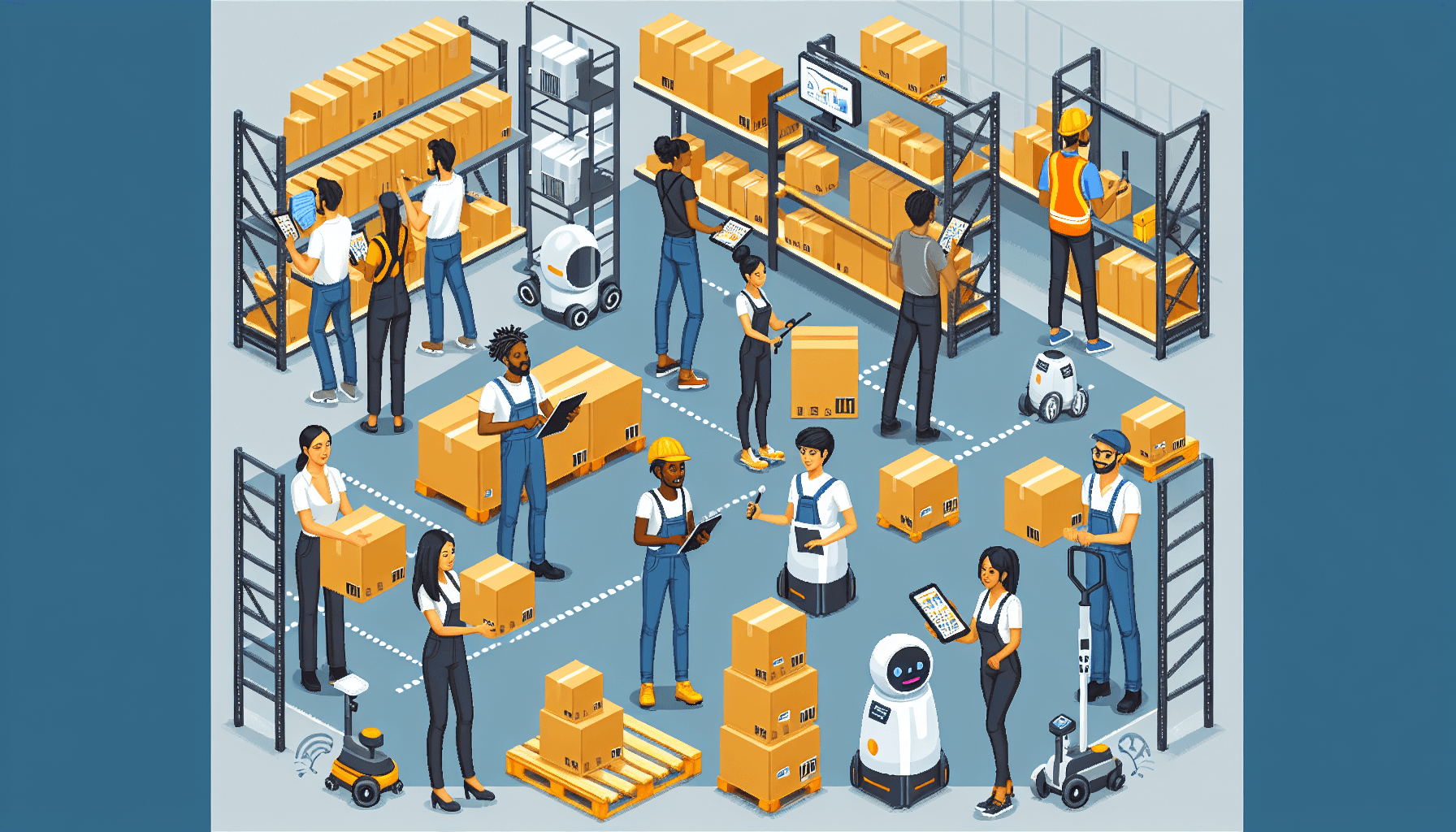

In today’s fast-paced and highly competitive business landscape, companies are constantly looking for ways to improve their warehouse operations. One of the emerging trends in warehouse management is the concept of collaborative warehouse networks. Collaborative warehouse networks involve multiple companies joining forces to create a shared distribution network, sharing resources, infrastructure, and technology to optimize their operations.

Improved Efficiency: By collaborating with other companies in a warehouse network, businesses can benefit from shared resources and infrastructure. This allows for better utilization of warehouse space, equipment, and personnel, leading to improved efficiency. With a collaborative warehouse network, companies can streamline their processes, reduce redundant tasks, and eliminate inefficiencies.

Reduced Costs: Collaborative warehouse networks can also lead to significant cost savings. By sharing warehouse space, companies can reduce their real estate costs. Additionally, pooling resources and sharing transportation networks can lead to cost savings on fuel, maintenance, and other related expenses. This cost optimization is particularly beneficial for small and medium-sized businesses that may not have the resources to invest in dedicated facilities and infrastructure.

Increased Flexibility: Warehouse networks also offer increased flexibility for businesses. In a rapidly changing market, companies may need to adjust their distribution strategies to meet changing customer demands. By being part of a collaborative warehouse network, businesses can more easily adapt their operations to accommodate fluctuations in demand, seasonal peaks, or other market dynamics. The shared resources and infrastructure in a warehouse network provide businesses with the agility to scale their operations as needed.

Enhanced Supply Chain Visibility: Supply chain visibility is a critical component of efficient warehouse management. Collaborative warehouse networks typically utilize advanced tracking and reporting systems that provide real-time visibility into inventory levels, order statuses, and transportation movements. This enhanced visibility allows businesses to make informed decisions, optimize inventory management, and improve customer service.

Shared Knowledge and Expertise: When companies collaborate in a warehouse network, they not only share physical resources but also knowledge and expertise. Businesses can learn from each other’s best practices, share industry insights, and collaborate on innovative solutions. This exchange of knowledge and expertise leads to continuous improvement within the warehouse network, benefiting all participating companies.

HCO Innovations understands the importance of collaborative warehouse networks in today’s competitive business landscape. Their warehouse optimization solutions are designed to facilitate and enhance the collaborative efforts of companies within a warehouse network. By leveraging their expertise and cutting-edge technology, HCO Innovations helps businesses achieve seamless coordination, effective resource allocation, and optimal performance in a collaborative warehouse network.

Harnessing the power of collaborative warehouse networks can be a game-changer for businesses looking to optimize their warehouse operations. By joining forces with other companies, businesses can gain access to shared resources, reduce costs, improve efficiency, and enhance their overall supply chain management. Through their innovative warehouse optimization solutions, HCO Innovations is empowering businesses to thrive in collaborative warehouse networks.

Experience the benefits of collaborative warehouse networks with HCO Innovations today!