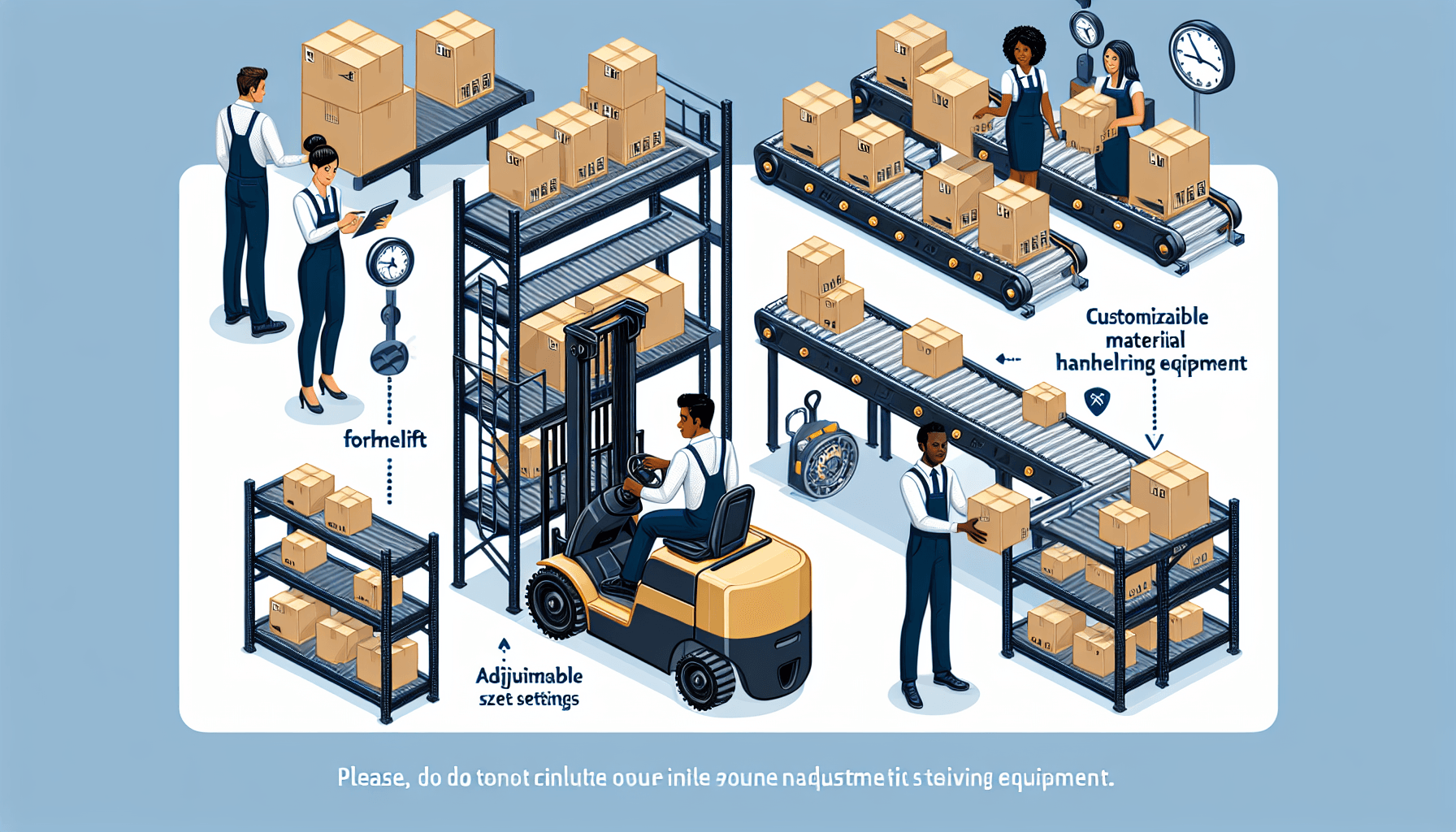

Welcome to the world of warehouse optimization! At HCO Innovations, we are passionate about helping businesses improve their warehouse operations. One key aspect of achieving optimal warehouse performance is the use of customizable material handling equipment. In this article, we will explore the benefits of using customizable material handling equipment and how it can transform your warehouse operations.

Enhanced Efficiency and Productivity

Customizable material handling equipment allows you to tailor the equipment to the specific needs of your warehouse. This means that you can optimize the design and functionality of the equipment based on the layout of your warehouse and the nature of your inventory. By using equipment that is specifically designed for your warehouse operations, you can greatly enhance efficiency and productivity.

For example, if you have narrow aisles in your warehouse, you can customize your forklifts to be more compact and agile, allowing them to maneuver easily in tight spaces. This will significantly reduce the time spent navigating through the aisles and improve overall productivity.

Furthermore, customizable material handling equipment can be equipped with advanced technologies such as automation and robotics. These technologies can streamline various warehouse processes, such as order picking and inventory management, leading to increased efficiency and productivity. By investing in customizable equipment, you can stay ahead of the competition and meet customer demands more effectively.

Improved Safety Measures

In any warehouse, safety should be a top priority. Customizable material handling equipment allows you to incorporate safety features that are specific to your warehouse needs. This can include features such as safety sensors, warning alarms, and ergonomic designs to reduce the risk of accidents and injuries.

For example, you can customize your pallet racks with safety features like beam guards and rack protectors to minimize the risk of pallets falling and causing injuries. By implementing these safety measures, you create a safer working environment for your employees and minimize the potential for costly accidents or damage to your inventory.

Customizable material handling equipment also allows you to adapt to changing safety regulations and industry standards. As regulations evolve, you can easily modify your equipment to ensure compliance. This flexibility is crucial in maintaining workplace safety and avoiding penalties or legal issues.

Cost-Effectiveness

Investing in customizable material handling equipment might seem like a significant upfront cost. However, in the long run, it can actually save you money. By customizing your equipment to match your warehouse needs, you can eliminate unnecessary features and functionalities, ensuring that you are only paying for what you truly need.

Customization also allows you to extend the lifespan of your equipment. Rather than replacing entire machinery when your needs change, you can simply modify or upgrade specific components, which is typically more cost-effective. This reduces the need for frequent equipment replacements and saves you money in the long term.

Additionally, customizable material handling equipment can improve overall operational efficiency, reducing costs associated with labor, time, and errors. With optimized equipment, you can streamline processes, minimize downtime, and improve inventory accuracy. This can lead to significant cost savings and increased profitability for your warehouse operations.

Conclusion

Customizable material handling equipment offers numerous benefits to warehouses looking to optimize their operations. From enhanced efficiency and productivity to improved safety measures and cost-effectiveness, the advantages are clear. At HCO Innovations, we specialize in providing customizable warehouse solutions that are tailored to meet your unique needs. To learn more about our material handling equipment management services, click here.