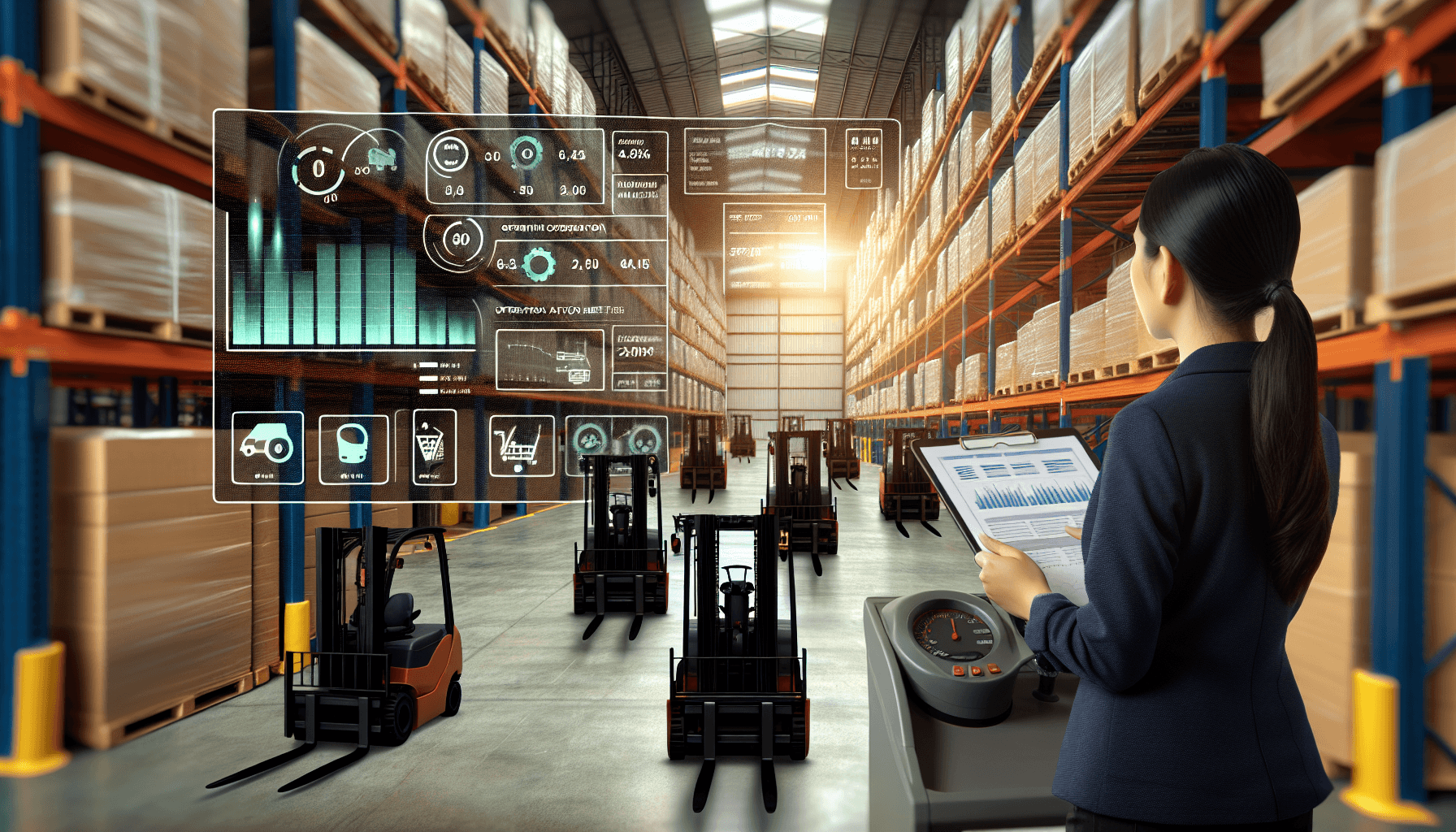

Today, warehouse operations are becoming increasingly complex and demanding. Companies are constantly striving to improve safety, increase productivity, enhance efficiency, and reduce costs within their warehouses. One area that plays a crucial role in achieving these goals is forklift fleet management. By implementing effective cost control programs for forklift fleets, businesses can experience a wide range of benefits.

Enhanced Cost Efficiency

One of the primary benefits of implementing a forklift fleet cost control program is improved cost efficiency. With proper management and control, companies can accurately track the utilization and maintenance costs of their forklifts. By monitoring this data, businesses can identify inefficiencies, such as underutilized or aging forklifts, and take appropriate action. This may involve reallocating resources, retiring older equipment, or implementing preventive maintenance strategies to reduce repair costs.

Additionally, a comprehensive cost control program enables organizations to allocate their budget effectively. By analyzing data on fuel consumption, repair costs, and other expenses, companies can make informed decisions when it comes to budget allocation. This ensures that resources are utilized optimally and unnecessary expenses are minimized.

Improved Safety

Safety is a top priority in any warehouse environment. Forklifts, being heavy machinery, can pose significant risks if not properly managed. Implementing a forklift fleet cost control program helps enhance safety in several ways.

Firstly, these programs incorporate strict maintenance and inspection schedules. Regular inspections and maintenance ensure that forklifts are in optimal working condition, reducing the risk of malfunctions or accidents caused by faulty equipment. By adhering to maintenance schedules, companies can identify and rectify potential safety hazards in a timely manner.

Furthermore, a comprehensive cost control program includes operator training and certification requirements. Ensuring that forklift operators are properly trained not only improves productivity but also reduces the likelihood of accidents. Well-trained operators are familiar with proper forklift operation techniques, safety procedures, and are more likely to make informed decisions when operating the equipment.

Lastly, cost control programs often incorporate telematics and monitoring systems. These systems provide real-time data on forklift utilization, operator behavior, and safety incidents. By having access to this data, companies can identify areas for improvement, implement corrective measures, and reinforce safe operating practices.

Increased Productivity and Efficiency

Forklift fleet cost control programs contribute to increased productivity and efficiency within warehouse operations. By reducing machine downtime through regular maintenance and proactive repairs, companies can ensure that forklifts are available and operational when required. This minimizes disruptions and delays in workflow, allowing for smoother and more efficient operations.

Additionally, improved fleet management enables better resource allocation. Cost control programs help identify peak utilization times, allowing companies to allocate resources accordingly. This may involve adjusting shifts, increasing the number of forklifts during high-demand periods, or reallocating forklifts between different areas of the warehouse to optimize productivity.

Another factor impacting productivity is operator behavior. Cost control programs often include monitoring systems that track operator performance. By analyzing data on factors such as speed, acceleration, and idle time, companies can identify opportunities for training and coaching to improve operator efficiency.

Moreover, having a cost control program in place allows businesses to measure and benchmark key performance indicators (KPIs). Companies can set targets for metrics such as forklift uptime, number of pallets moved per hour, or operational costs. By regularly reviewing these metrics, businesses can identify areas for improvement, implement best practices, and benchmark their performance against industry standards.

HCO Innovations specializes in providing warehouse optimization solutions, including comprehensive forklift fleet cost control programs. Their industry-leading expertise and cutting-edge technology can help businesses enhance safety, improve cost efficiency, and increase productivity within their warehouses.

In conclusion, implementing a forklift fleet cost control program offers a range of benefits for warehouse operations. From enhanced cost efficiency and improved safety to increased productivity and efficiency, these programs enable businesses to optimize their forklift fleet management. By partnering with a trusted provider like HCO Innovations, companies can harness the power of these programs to drive success in their warehouse operations.

What is a forklift fleet cost control program?

A forklift fleet cost control program is a system implemented by businesses to manage and reduce the costs associated with operating a forklift fleet. It involves analyzing expenses, optimizing maintenance schedules, improving operator efficiency, and minimizing downtime.

Why is it important to implement a forklift fleet cost control program?

Implementing a forklift fleet cost control program is important for several reasons. Firstly, it helps businesses reduce operating expenses and overall fleet costs, leading to significant savings in the long run. Secondly, it improves operational efficiency by optimizing maintenance and reducing downtime. Lastly, it ensures compliance with safety regulations, reducing the risk of accidents and associated costs.

What are the main benefits of a forklift fleet cost control program?

Implementing a forklift fleet cost control program offers numerous benefits. Some of the main advantages include reduced operating costs, improved productivity, extended equipment lifespan, enhanced safety, better regulatory compliance, and increased overall profitability for businesses.

How can a forklift fleet cost control program help in optimizing maintenance schedules?

A forklift fleet cost control program helps optimize maintenance schedules by implementing a proactive approach. It includes regular inspections, planned preventive maintenance, timely repairs, and tracking of equipment performance. By adhering to a well-planned maintenance schedule, businesses can minimize breakdowns, extend equipment lifespan, and reduce costly emergency repairs.

Can a forklift fleet cost control program help reduce operator-related costs?

Yes, a forklift fleet cost control program can help reduce operator-related costs. By providing comprehensive training programs, promoting safe operating practices, and monitoring operator performance, businesses can minimize accidents, damage to equipment or inventory, and associated costs. Additionally, optimizing operator schedules and evaluating workload distribution can further enhance productivity and reduce labor expenses.

What role does technology play in a forklift fleet cost control program?

Technology plays a crucial role in a forklift fleet cost control program. Fleet management software, telematics systems, and sensor technologies can be utilized to monitor equipment usage, track maintenance activities, and gather valuable data for analysis. By leveraging technology, businesses can make informed decisions, identify areas for improvement, and optimize their forklift fleet operations.

Is implementing a forklift fleet cost control program complex?

Implementing a forklift fleet cost control program does require planning and organization, but it doesn't have to be overly complex. By breaking it down into manageable steps, setting clear goals, and involving key stakeholders, businesses can successfully implement a cost control program tailored to their specific needs. Working with trusted industry experts or consultants can also simplify the process and ensure a smooth transition.

How long does it take to see the benefits of a forklift fleet cost control program?

The time it takes to see the benefits of a forklift fleet cost control program may vary depending on various factors such as the size of the fleet, current operating practices, and the extent of changes implemented. However, businesses can typically start seeing positive results within a few months of implementing the program. Continuous monitoring and improvement will ensure ongoing benefits in the long term.

Can a forklift fleet cost control program be customized for different industries?

Yes, a forklift fleet cost control program can be customized to suit the specific needs and requirements of different industries. The cost control strategies, maintenance schedules, and operational practices may vary based on factors such as industry regulations, types of materials handled, and the nature of the business. Customizing the program ensures it effectively addresses the challenges and opportunities unique to each industry.

How can businesses get started with implementing a forklift fleet cost control program?

To get started with implementing a forklift fleet cost control program, businesses should first conduct a thorough assessment of their current fleet operations and expenses. This evaluation will help identify areas for improvement and set goals for cost reduction. Next, it's important to develop a comprehensive plan outlining cost control strategies, maintenance schedules, and training programs. Finally, implementing the plan and regularly monitoring progress will ensure the program's success.

The Evolution of Forklift Technology and Its Impact on Warehousing Efficiency

The Evolution of Forklift Technology and Its Impact on Warehousing Efficiency

The Role of Forklifts in Warehouse Operations

Warehouse operations play a crucial role in the supply chain management of various industries. Efficient management of inventory, picking, and shipping processes is essential for ensuring smooth operations and timely delivery of products. Forklifts, as versatile handling equipment, have been a staple in warehouses for decades.

Forklifts have undergone a remarkable evolution since their inception, revolutionizing the way materials are handled within warehouses. The advancements in forklift technology have significantly impacted warehouse efficiency, making tasks quicker, safer, and more cost-effective. In this article, we will explore the evolution of forklift technology and its impact on warehousing efficiency.

The Early Days: Basic Functionality

In the early days, forklifts were simple in design and function. They were primarily used for lifting and moving goods within a warehouse. These early models had limited lifting capacities and required manual operation, with the operator standing or walking alongside the forklift. As technology advanced, electric forklifts replaced some of the manual labor, making the lifting process less physically demanding.

Improved safety features such as overhead guard protection and seat belts were introduced to enhance operator safety. However, these early forklift models had limited maneuverability and were less efficient in terms of speed and productivity.

The Emergence of Electric Forklifts

The emergence of electric forklifts brought about significant improvements in warehouse operations. Electric forklifts offered quieter operation, zero emissions, and lower maintenance costs compared to their internal combustion engine counterparts.

Electric forklifts also introduced features like regenerative braking, which not only improved energy efficiency but also extended battery life. These advancements allowed forklifts to operate for longer periods without interruptions for recharging, thereby increasing productivity.

Furthermore, electric forklifts proved to be more maneuverable and versatile than their predecessors. The introduction of smaller electric forklift models with narrow aisles enabled warehouses to utilize their space more efficiently, maximizing storage capacity.

The Rise of Automation

With the continuous innovation in warehouse technology, the rise of automation has revolutionized the way warehouses operate. Automated guided vehicles (AGVs) and autonomous forklifts are increasingly being used to streamline warehousing processes.

AGVs are self-driving vehicles guided by sensors and programmed routes. These vehicles can handle repetitive tasks such as transporting goods within the warehouse, reducing the reliance on human operators for mundane manual labor. Autonomous forklifts are equipped with advanced navigation systems, enabling them to operate independently without the need for constant human intervention.

The implementation of automation in warehousing has numerous benefits. It improves accuracy, reduces human error, and increases operational efficiency. Automated systems can work 24/7, significantly improving productivity and throughput. Additionally, automation reduces the risk of accidents and injuries, ensuring a safer working environment for warehouse employees.

The Future of Forklift Technology

The future of forklift technology is expected to bring even more advancements in warehouse efficiency. Some of the trends to look out for include:

- Electric Forklifts with Longer Battery Life: Companies are continuously working on developing electric forklifts with longer battery life, reducing the need for frequent recharging and improving overall productivity.

- Integration with Warehouse Management Systems: Forklifts are being integrated with advanced warehouse management systems (WMS) to optimize routing and improve communication between forklift operators and the warehouse management team.

- Data Analytics for Predictive Maintenance: The utilization of data analytics in forklifts allows for predictive maintenance, identifying potential issues before they lead to costly breakdowns and minimizing downtime.

- Improved Safety Features: Forklift manufacturers are continually enhancing safety features, such as advanced obstacle detection systems and proximity sensors, to reduce the risk of accidents and injuries in the warehouse.

As technology continues to evolve, forklifts will play an increasingly pivotal role in the optimization of warehouse operations. HCO Innovations, a leading management consulting firm specializing in warehouse optimization and forklift fleet management, is at the forefront of helping companies leverage these advancements for maximum efficiency and cost reduction.

HCO Innovations offers comprehensive services including warehouse layout evaluation, safety assessments, and turnkey maintenance solutions. By leveraging advanced cost-tracking software and their collaborative "boots on the ground" approach, HCO Innovations helps clients across industries achieve significant cost reductions and operational efficiency.

Whether it's analyzing warehouse layouts, identifying potential bottlenecks, or implementing advanced technology solutions, HCO Innovations' tailored approach consistently delivers exceptional return on investment. Their expertise in optimizing warehouse operations and reducing material handling costs makes them a trusted partner for businesses seeking to improve efficiency and profitability in their warehousing processes.

To learn more about how HCO Innovations can help optimize your warehouse operations, visit their website today.