Running an efficient and productive warehouse operation is crucial for any business. One of the key elements to achieving this is optimizing the performance of your forklift fleet. A well-managed forklift fleet can result in increased safety, improved productivity, reduced downtime, and significant cost savings. One tool that can greatly assist in achieving these goals is a forklift fleet performance dashboard.

What is a Forklift Fleet Performance Dashboard?

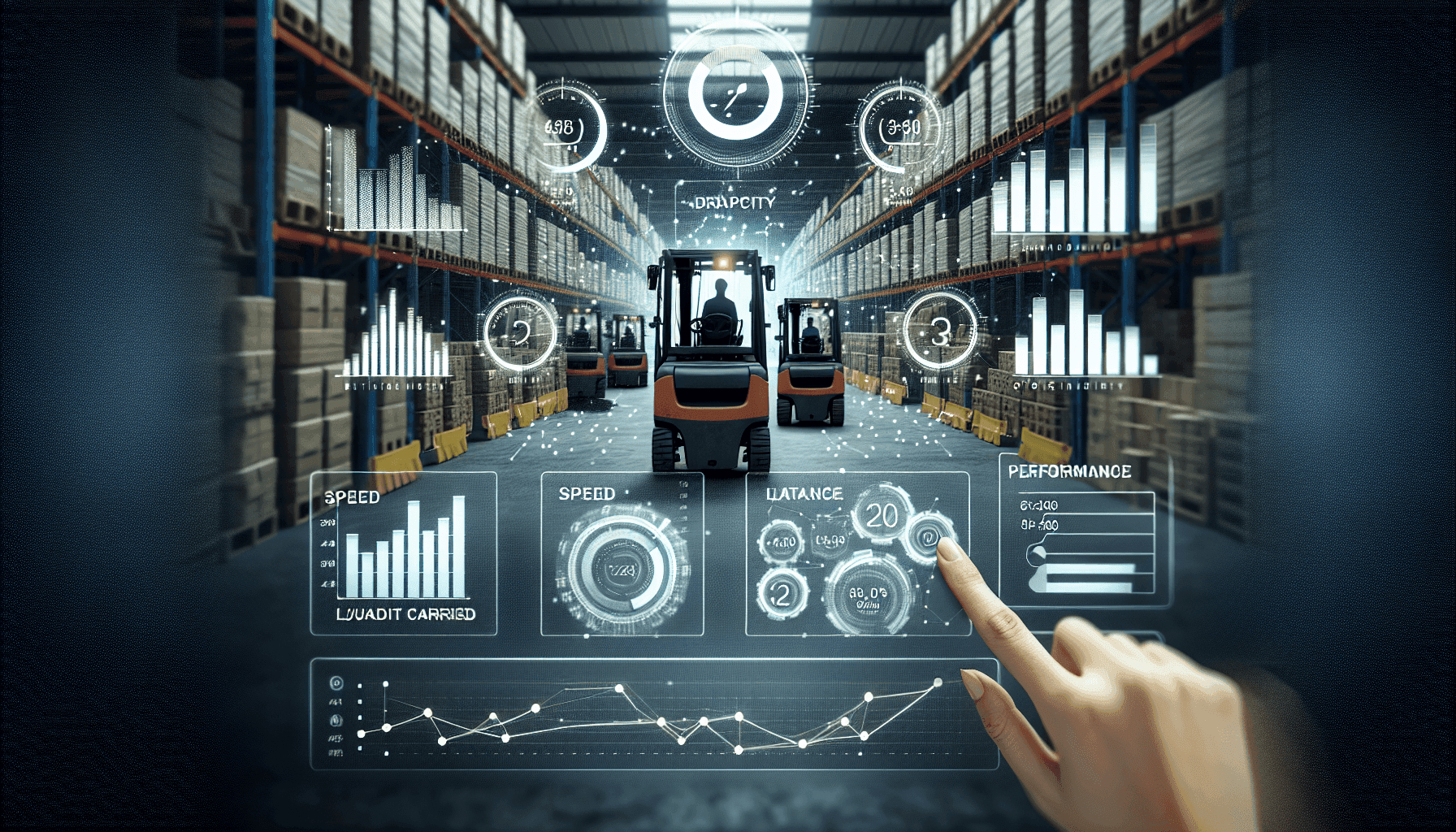

A forklift fleet performance dashboard is a software tool that allows you to monitor and analyze the performance of your forklift fleet in real-time. It provides you with valuable insights into the operation of your forklifts, helping you make data-driven decisions and take proactive measures to optimize their performance. This type of dashboard collects data from various sources, such as forklift telematics devices, and presents it in a user-friendly and customizable interface.

By using a forklift fleet performance dashboard, warehouse managers and supervisors can easily track important performance metrics and identify areas for improvement. These dashboards typically include key performance indicators (KPIs) like utilization rates, fuel consumption, maintenance schedules, operator certifications, and safety incidents. They provide a comprehensive overview of the fleet’s performance, allowing you to identify trends, detect inefficiencies, and implement targeted strategies to improve overall operations.

The Benefits of Using a Forklift Fleet Performance Dashboard

Investing in a forklift fleet performance dashboard can bring numerous benefits to your warehouse operations. Here are some of the key advantages:

1. Enhanced Safety:

A forklift fleet performance dashboard helps improve safety standards in your warehouse. It allows you to monitor operator behavior, such as speed, braking patterns, and compliance with safety protocols. This data can help identify potential risks and enable you to take preventive actions to avoid accidents and injuries. Additionally, the dashboard can track maintenance schedules, ensuring that forklifts are in proper working condition and reducing the likelihood of breakdowns that could compromise safety.

2. Increased Productivity:

By monitoring KPIs such as utilization rates and forklift idle time, a fleet performance dashboard allows you to identify operational inefficiencies. You can pinpoint where time is being wasted and implement strategies to optimize resources. This can lead to improved productivity as well as better allocation of forklifts to match changing demand patterns. Additionally, the dashboard can provide real-time alerts for any potential bottlenecks or issues that may hinder productivity, enabling you to take immediate corrective actions.

3. Better Maintenance Management:

A forklift fleet performance dashboard enables you to track maintenance schedules, monitor equipment status, and identify potential maintenance issues. By staying on top of maintenance tasks, you can reduce unplanned downtime and prevent costly breakdowns. With the ability to schedule maintenance based on actual usage and performance data, you can optimize maintenance processes and ensure maximum uptime for your forklift fleet.

4. Cost Savings:

Implementing a forklift fleet performance dashboard can result in significant cost savings. By optimizing forklift utilization and reducing idle time, you can lower fuel consumption and extend the lifespan of your equipment. Additionally, proactive maintenance management reduces the likelihood of major repairs and replacement costs. Moreover, the dashboard allows you to track operator certifications, ensuring that only trained and qualified individuals operate the forklifts, minimizing the risk of accidents and associated costs.

5. Data-Driven Decision Making:

A forklift fleet performance dashboard provides you with valuable data and insights that enable informed decision-making. The visual representation of performance metrics and trends allows you to easily identify patterns, strengths, and areas for improvement. With access to real-time data, you can make informed decisions that optimize operations and drive overall warehouse efficiency.

As you can see, implementing a forklift fleet performance dashboard offers numerous benefits for warehouse operations. It enhances safety, boosts productivity, improves maintenance management, reduces costs, and supports data-driven decision-making. If you’re looking to optimize your forklift fleet and drive efficiency in your warehouse, consider integrating a forklift fleet performance dashboard like the one offered by HCO Innovations.