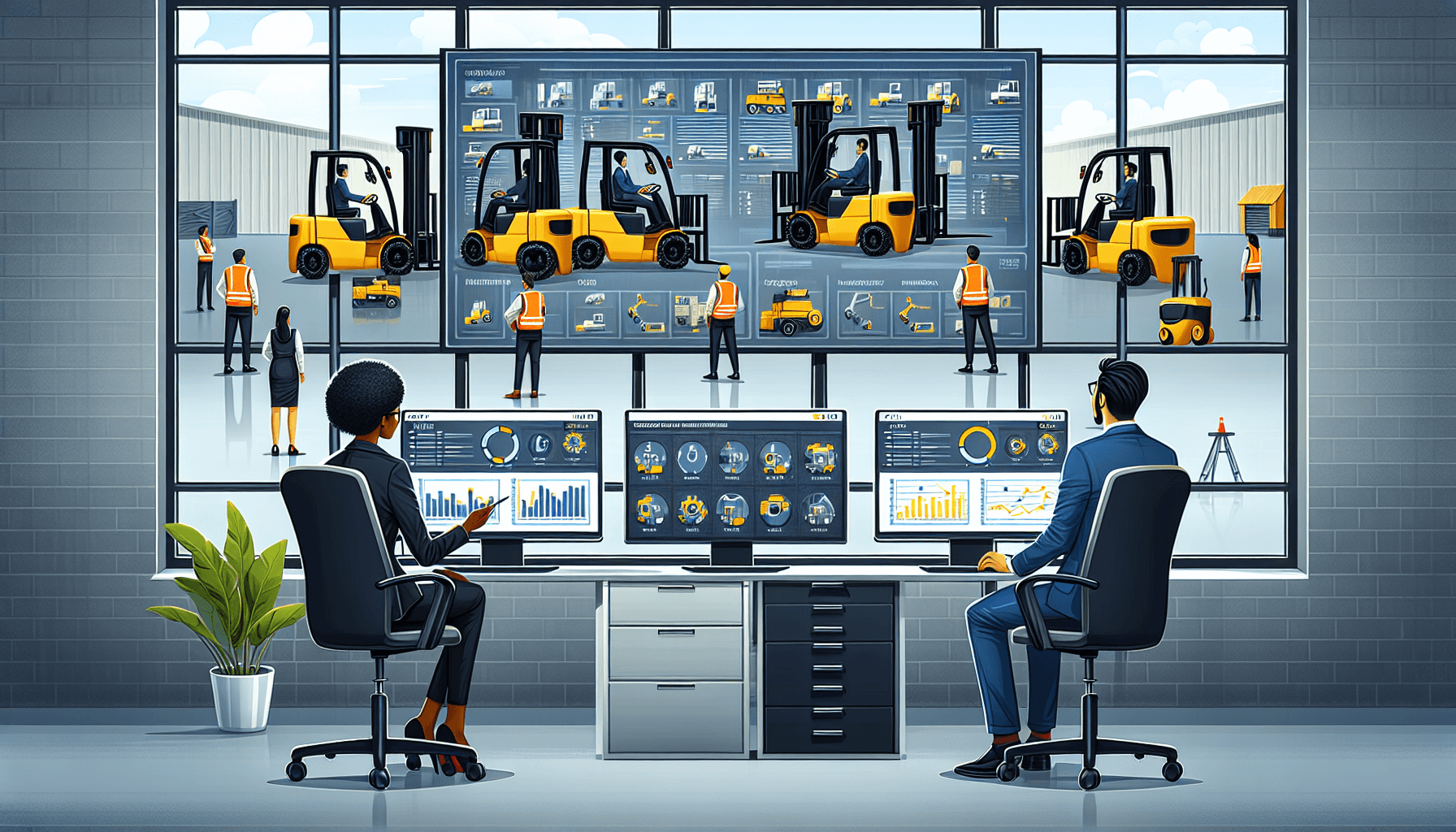

Implementing a forklift fleet management system can revolutionize your warehouse operations and bring numerous benefits to your business. In this article, we will explore the advantages of adopting such a system and how it can optimize your warehouse processes.

Improved Efficiency

One of the primary benefits of a forklift fleet management system is the improved efficiency it brings to your warehouse operations. Through the use of advanced technologies and real-time data, the system allows for better planning and coordination of forklift tasks. Operators can easily track the location of each forklift, allocate resources efficiently, and prioritize tasks accordingly.

This enhanced level of visibility and control enables your warehouse to operate at maximum efficiency, reducing downtime and eliminating bottlenecks. With a forklift fleet management system, you can ensure that your forklifts are effectively utilized and that tasks are completed in a timely manner.

Enhanced Safety

Safety is always a top priority in any warehouse environment. Implementing a forklift fleet management system can greatly enhance safety measures and minimize the risk of accidents. The system includes features such as speed monitoring, collision avoidance, and real-time alerts to prevent potential hazards.

By tracking forklift movements and monitoring operator behavior, the system can provide valuable insights and identify any safety issues or training needs. This proactive approach to safety helps to create a safer working environment for your employees and reduces the likelihood of accidents and injuries.

Optimized Maintenance

Proper maintenance of your forklift fleet is crucial for ensuring their longevity and uninterrupted operations. With a forklift fleet management system in place, you can easily schedule and track maintenance tasks, such as routine inspections and repairs.

The system can provide timely notifications for maintenance requirements based on usage and operating hours. This proactive approach helps to prevent breakdowns and costly repairs, as well as prolongs the lifespan of your forklifts. By keeping your forklifts in optimal working condition, you can minimize downtime and improve overall productivity.

Cost Savings

Implementing a forklift fleet management system can lead to significant cost savings for your business. By optimizing operations and maximizing efficiency, you can reduce labor costs and increase productivity. The system allows you to better allocate resources, eliminate unnecessary tasks, and streamline processes, ultimately resulting in improved cost-effectiveness.

Additionally, the system’s maintenance tracking capabilities enable you to stay on top of maintenance schedules, reducing the likelihood of unexpected breakdowns and costly repairs. By proactively managing maintenance, you can minimize downtime and avoid unnecessary expenses.

Real-time Reporting and Analytics

A forklift fleet management system provides real-time reporting and analytics, giving you valuable insights into your warehouse operations. You can monitor key performance indicators (KPIs) such as forklift utilization, operator productivity, and task completion times.

With access to real-time data and comprehensive reports, you can identify areas for improvement, optimize workflows, and make data-driven decisions. This level of visibility allows you to track performance, measure efficiency, and implement continuous improvements to enhance overall warehouse operations.

By investing in a forklift fleet management system, you can transform your warehouse into a well-oiled machine, optimizing safety, efficiency, and productivity. HCO Innovations offers top-of-the-line forklift fleet management solutions tailored to meet your specific needs. Visit their website to learn more about how they can help you revolutionize your warehouse operations.

What is a forklift fleet management system?

A forklift fleet management system is a software solution that allows businesses to efficiently manage their forklift fleet. It provides real-time visibility and control over forklift operations, including monitoring usage, scheduling maintenance, and optimizing fleet performance.

Why should I implement a forklift fleet management system?

Implementing a forklift fleet management system offers numerous benefits to businesses. It improves operational efficiency, reduces costs, enhances safety, streamlines maintenance processes, and provides valuable insights into fleet performance and utilization.

How does a forklift fleet management system improve operational efficiency?

A forklift fleet management system optimizes fleet utilization by providing real-time visibility into forklift locations and status. It helps businesses streamline workflows, eliminate unnecessary downtime, identify bottlenecks, and allocate resources effectively, resulting in improved operational efficiency.

What cost savings can I expect by implementing a forklift fleet management system?

By implementing a forklift fleet management system, businesses can save on various costs. These include reducing fuel consumption through route optimization, minimizing maintenance expenses by scheduling proactive service, and minimizing equipment damage through improved operator accountability.

How does a forklift fleet management system enhance safety?

A forklift fleet management system promotes better safety practices by monitoring operator behavior, such as speeding or harsh braking, and delivering real-time alerts or training resources. It also ensures compliance with safety regulations and can provide insights into accident trends for proactive prevention measures.

Does implementing a forklift fleet management system require special hardware?

While some forklift fleet management systems may require additional hardware, many solutions can utilize the existing onboard technology in modern forklifts. This can include GPS, telematics devices, sensors, or data loggers, which can be integrated with the management system for real-time data monitoring.

How can a forklift fleet management system improve maintenance processes?

A forklift fleet management system enables businesses to schedule and track maintenance tasks based on usage or time intervals. It provides reminders for routine inspections, tracks service history, and can predict maintenance needs, ensuring that the forklift fleet operates at optimal performance and extends its lifespan.

Can a forklift fleet management system help with compliance reporting?

A forklift fleet management system simplifies compliance reporting by automating the collection and analysis of relevant data. It can generate reports on operator certifications, inspections, maintenance records, and other compliance-related requirements, ensuring that businesses stay compliant with industry and regulatory standards.

How can a forklift fleet management system improve productivity?

A forklift fleet management system boosts productivity by eliminating manual paperwork, optimizing task assignment, and minimizing equipment downtime. It allows businesses to track key performance indicators, identify inefficiencies, and make data-driven decisions to enhance overall productivity and meet operational goals.

Will implementing a forklift fleet management system require additional training for my staff?

Implementing a forklift fleet management system may require some training for your staff, but most solutions are designed to be user-friendly and intuitive. Training can be provided to familiarize operators, supervisors, and maintenance personnel with the system's functionalities and help them maximize its benefits.

The Impact of Technology on Warehouse Efficiency.

The impact of technology on warehouse efficiency cannot be overstated. In today's fast-paced business environment, warehouses and distribution centers are constantly looking for ways to improve their operations, increase productivity, and reduce costs. One of the key factors that contribute to achieving these goals is the adoption of technology.

Streamlining Warehouse Operations with Technology

Technology has revolutionized the way warehouses operate, making them more efficient and productive than ever before. Let's take a look at some of the ways technology is transforming warehouse operations:

- Warehouse Management Systems (WMS):

A Warehouse Management System is a software application that helps manage and control various warehouse operations. It provides real-time visibility into inventory levels, automates processes like receiving, picking, and shipping, and optimizes warehouse layout and storage space. By implementing a WMS, warehouses can streamline their operations, reduce errors, and improve overall efficiency.

- Barcode and RFID Technology:

Barcode and RFID (Radio Frequency Identification) technology play a crucial role in improving warehouse efficiency. Barcodes are used to label products, pallets, and locations, enabling accurate tracking and identification. RFID tags, on the other hand, use radio waves to transmit information, allowing for quick and automatic scanning of products. These technologies help reduce manual errors, improve inventory accuracy, and speed up processes like order fulfillment and cycle counting.

- Automated Guided Vehicles (AGVs):

AGVs are self-driving vehicles that can move materials and products within a warehouse without the need for human intervention. They use sensors and navigation systems to safely navigate through the warehouse and execute tasks like picking, transporting, and sorting items. AGVs not only save time but also increase efficiency by reducing human error and improving throughput. They are especially useful in large warehouses with high volumes of materials.

- Warehouse Robotics:

Robotic systems are increasingly being used in warehouses to automate repetitive and labor-intensive tasks. For example, robots can be used for picking and packing items, loading and unloading trucks, and even performing inventory audits. These robots work alongside human workers, enhancing their efficiency and productivity. With advancements in machine learning and artificial intelligence, warehouse robotics is becoming more sophisticated and capable.

These are just a few examples of how technology is transforming warehouse operations. The benefits of adopting these technologies include:

- Increased Productivity: Technology enables warehouses to handle higher volumes of materials and processes, leading to increased productivity and throughput.

- Improved Accuracy: Automated systems reduce human error, resulting in improved accuracy in tasks such as order fulfillment and inventory management.

- Optimized Space Utilization: Warehouse technology solutions help optimize storage space, ensuring efficient use of available square footage.

- Enhanced Safety: Technology such as AGVs and robotics can help reduce workplace accidents by taking over dangerous tasks and improving overall safety in the warehouse environment.

At HCO Innovations, we understand the importance of technology in warehouse optimization. As a leading management consulting firm, we specialize in helping warehouses and distribution centers leverage technology solutions to improve operational efficiency and reduce costs. Our team of experts can assist in evaluating your warehouse layout, implementing WMS systems, advising on barcode and RFID technology, and implementing automation solutions such as AGVs and robotics.

With our collaborative approach and advanced cost-tracking software, we can deliver tailored solutions that consistently provide exceptional return on investment. We have a proven track record of helping clients across industries like distribution, manufacturing, and food processing achieve significant cost reductions and operational efficiency.

If you're ready to take your warehouse operations to the next level, contact us today and see how HCO Innovations can help you optimize your warehouse and reduce material handling costs.