When it comes to warehouse operations, efficiency and cost-effectiveness play a crucial role in ensuring the success of a business. In today’s competitive business landscape, companies are constantly striving to optimize their warehouse processes to stay ahead of the curve. This is where lean warehousing practices come into play.

What are Lean Warehousing Practices?

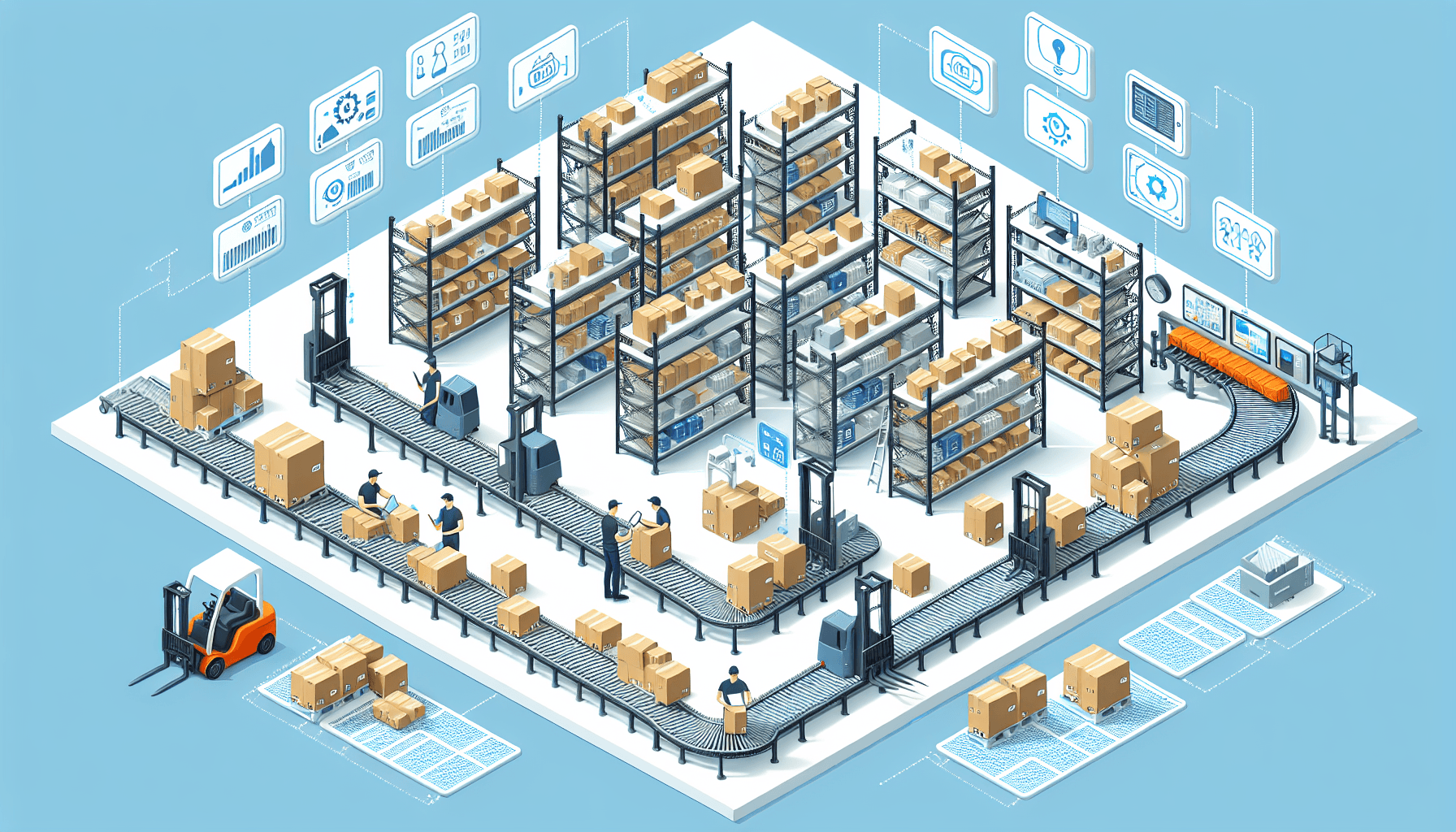

Lean warehousing is a systematic approach to managing warehouse operations with the aim of eliminating waste, reducing costs, and improving overall efficiency. Inspired by the principles of lean manufacturing, lean warehousing focuses on streamlining workflows, reducing inventory, and maximizing space utilization to create a more agile and productive warehouse environment.

Implementing lean warehousing practices involves analyzing and redesigning various aspects of warehouse operations, including inventory management, resource allocation, and process optimization. By identifying and eliminating non-value-added activities, organizations can improve productivity, reduce lead times, and ultimately enhance customer satisfaction.

The Benefits of Lean Warehousing Practices

1. Increased Efficiency: One of the key benefits of lean warehousing practices is increased operational efficiency. By eliminating waste and streamlining processes, organizations can reduce the time and effort required to complete tasks. This leads to faster order fulfillment, improved accuracy, and ultimately, higher customer satisfaction.

2. Cost Savings: Lean warehousing practices also offer significant cost savings. By reducing inventory levels and optimizing space utilization, organizations can minimize storage costs. Additionally, by eliminating unnecessary steps and reducing the need for overtime or additional resources, companies can decrease labor costs.

3. Improved Safety: Safety is a top priority in warehouses, and adopting lean practices can contribute to a safer work environment. By reducing clutter, implementing standardized processes, and emphasizing employee training, organizations can enhance safety measures and minimize the risk of accidents or injuries.

4. Enhanced Flexibility: Lean warehousing practices enable organizations to be more flexible and responsive to changing market demands. By improving inventory management and reducing lead times, companies can quickly adapt to fluctuating customer needs or market trends. This agility allows businesses to stay competitive and maintain customer loyalty.

5. Employee Engagement: Involving employees in the lean transformation process can greatly improve morale and engagement. Lean practices empower employees by giving them a voice in identifying inefficiencies, suggesting improvements, and participating in the implementation of solutions. This collaborative approach fosters a culture of continuous improvement and boosts employee satisfaction.

6. Increased Sustainability: Lean warehousing practices contribute to a more sustainable future by promoting environmental responsibility. By reducing waste and optimizing energy usage, organizations can significantly reduce their carbon footprint and make a positive impact on the environment. This not only aligns with corporate social responsibility goals but can also attract environmentally-conscious customers.

7. Competitive Advantage: Implementing lean warehousing practices gives businesses a competitive edge in the market. By optimizing processes and consistently delivering high-quality products or services, organizations can differentiate themselves from the competition. This can lead to increased customer loyalty, repeat business, and positive word-of-mouth referrals.

When it comes to implementing lean warehousing practices, partnering with a professional warehouse optimization solutions provider like HCO Innovations is key. With their expertise and experience in enhancing safety, productivity, and efficiency in warehouse operations, HCO Innovations can help businesses unlock the full potential of lean warehousing practices.

Click here to learn more about HCO Innovations and how they can assist in analyzing your warehouse costs and implementing lean warehousing practices.