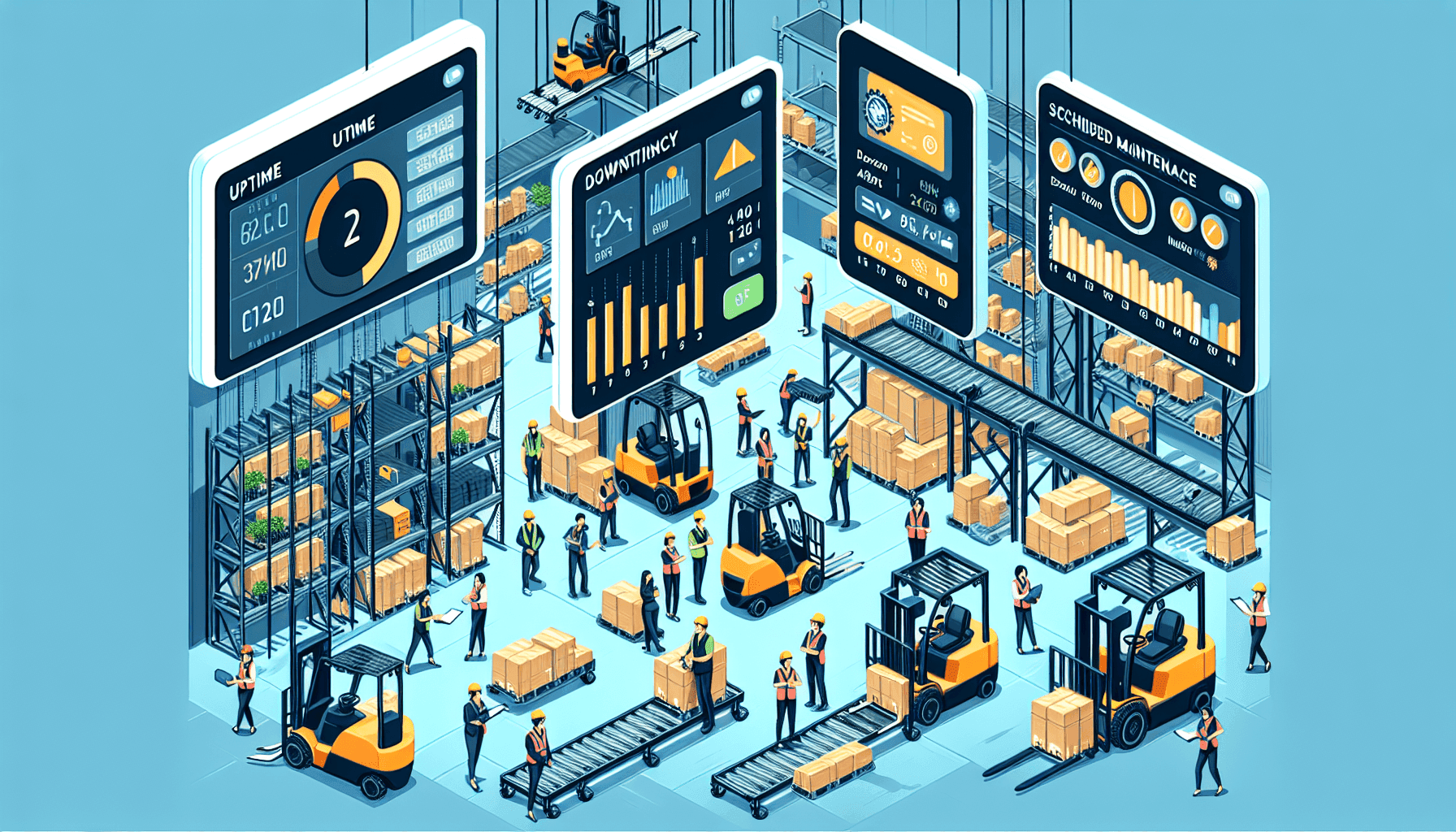

Maintenance metrics play a crucial role in optimizing warehouse operations and ensuring the smooth functioning of material handling equipment (MHE). By tracking and analyzing key metrics, warehouse managers can closely monitor the performance, reliability, and efficiency of their MHE fleet. This valuable data enables them to make informed decisions, identify areas for improvement, and implement proactive maintenance strategies.

The Importance of Maintenance Metrics

Having a comprehensive understanding of the condition and performance of the MHE fleet is essential for successful warehouse management. Maintenance metrics provide measurable insights into various aspects of equipment performance, including uptime, downtime, preventive maintenance, and repairs. These metrics allow warehouse managers to:

- Monitor Equipment Performance: Maintenance metrics enable warehouse managers to track the performance of individual MHE units and the fleet as a whole. By analyzing metrics like equipment uptime and downtime, managers can identify patterns and trends, allowing them to optimize equipment utilization and minimize disruptions.

- Identify Maintenance Needs: Regular maintenance is crucial for keeping MHE in optimal condition and preventing breakdowns. By analyzing metrics related to preventive maintenance, such as maintenance schedule adherence and percentage of preventive maintenance completed, managers can ensure that maintenance tasks are being carried out on time and as per schedule.

- Improve Efficiency: Maintenance metrics offer valuable insights into the efficiency of MHE operations. By tracking metrics like time to repair and mean time between failures (MTBF), warehouse managers can identify opportunities to streamline processes, reduce downtime, and improve overall operational efficiency.

- Optimize Inventory Management: Accurate maintenance metrics provide visibility into the health of the MHE fleet, allowing managers to make data-driven decisions regarding equipment replacements, retirements, or upgrades. This helps optimize inventory management and ensure that the right equipment is available when needed.

Key Maintenance Metrics for MHE

When it comes to monitoring the performance of material handling equipment, several key metrics are essential. Let’s take a look at some of the most important maintenance metrics:

- Equipment Uptime and Downtime: This metric measures the amount of time that MHE is available and in operational condition (uptime) versus the time it is unavailable or not functioning correctly (downtime). It provides insight into equipment reliability and can help identify causes of downtime, such as breakdowns or maintenance tasks.

- Preventive Maintenance Compliance: This metric tracks the percentage of planned preventive maintenance tasks that are completed on time. It helps ensure that equipment is regularly inspected, serviced, and maintained according to the recommended schedule, reducing the risk of sudden failures or breakdowns.

- Mean Time Between Failures (MTBF): MTBF measures the average time or operating hours between equipment failures. It provides an estimate of equipment reliability and helps identify areas that require improvement or increased maintenance efforts.

- Mean Time to Repair (MTTR): MTTR measures the average time it takes to repair a failed or malfunctioning MHE unit. Tracking this metric allows warehouse managers to identify bottlenecks in the repair process and implement strategies to minimize downtime.

- Maintenance Costs: This metric tracks the expenses associated with MHE maintenance, including labor, spare parts, and repairs. By analyzing maintenance costs, warehouse managers can identify opportunities to optimize maintenance activities and reduce overall expenditure.

By regularly monitoring these key maintenance metrics, warehouse managers can identify areas for improvement, implement preventive maintenance strategies, and make data-driven decisions regarding equipment maintenance, replacements, and upgrades.

Implementing an advanced warehouse optimization solution, like the one offered by HCO Innovations, can greatly simplify the process of tracking and analyzing maintenance metrics for MHE. With HCO Innovations’ material handling equipment management solution, warehouse managers gain access to a comprehensive suite of tools and analytics that provide real-time insights into equipment performance, maintenance needs, and overall fleet efficiency. This allows them to proactively manage their MHE fleet, optimize maintenance processes, and improve operational efficiency.

Are you ready to take the next step in enhancing the performance of your material handling equipment? Check out HCO Innovations’ material handling equipment management solution to learn more!