Warehouse operations play a vital role in the overall success of a business. If not properly managed, warehouses can become chaotic and inefficient, leading to increased costs and reduced customer satisfaction. That’s why it’s essential for companies to invest in warehouse optimization solutions to improve safety, productivity, efficiency, and cost-effectiveness.

The Importance of MHE Standardization

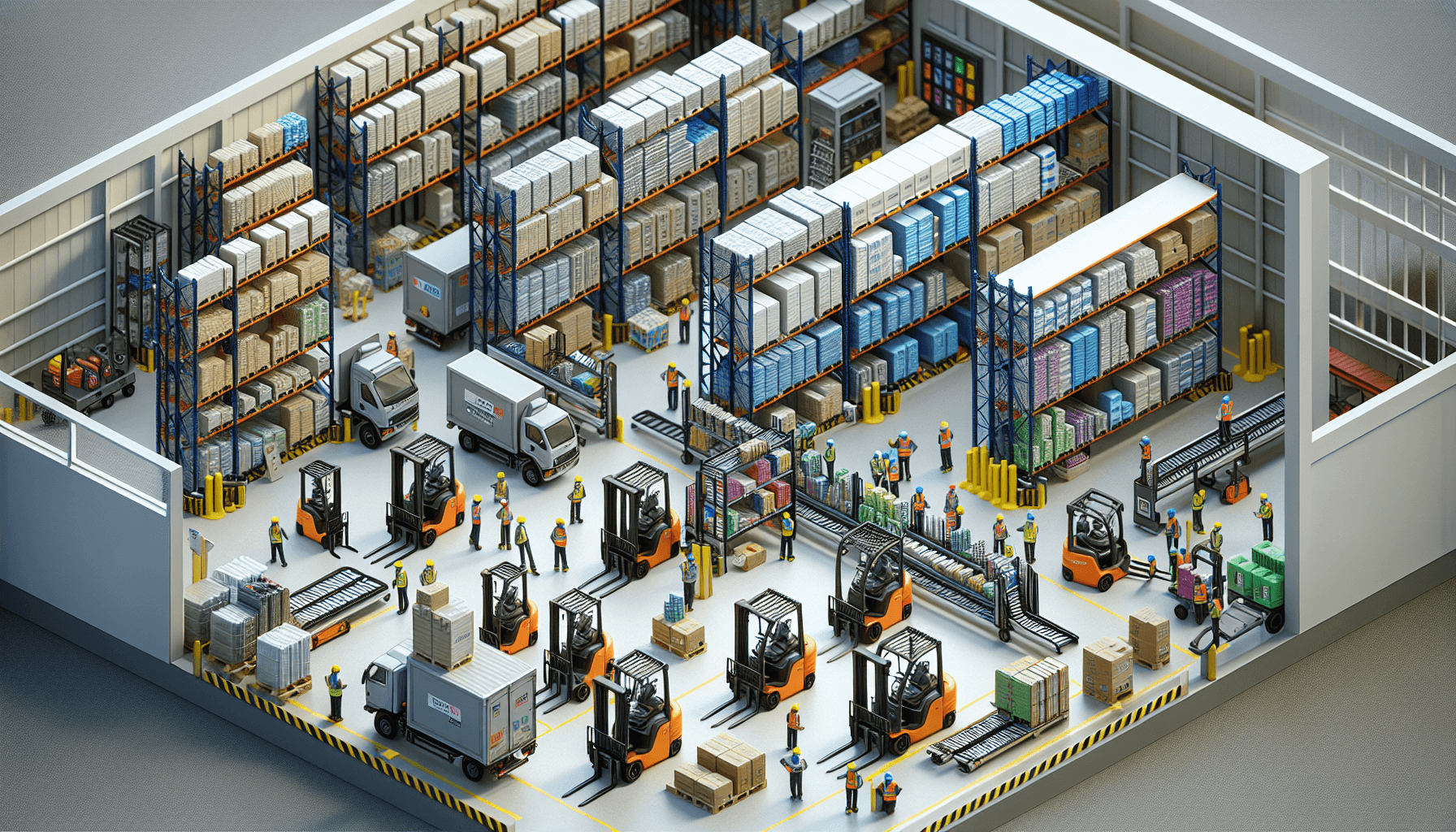

One important aspect of warehouse optimization is Material Handling Equipment (MHE) standardization. MHE refers to the machinery and tools used in warehouses to handle, store, and transport goods. Standardization involves using uniform equipment throughout the warehouse, ensuring that all equipment meets specific criteria and is compatible with each other.

The benefits of MHE standardization cannot be understated. Let’s take a closer look at why it is crucial for optimizing warehouse operations:

1. Increased Efficiency

Standardizing MHE allows for streamlined processes and reduces the time required for training employees. When all employees are working with the same equipment, they become familiar with its operation, minimizing errors and delays. This increased efficiency leads to improved throughput and faster order fulfillment, resulting in happier customers.

2. Enhanced Safety

Implementing standardized MHE promotes a safer working environment. When equipment is consistent throughout the warehouse, employees become more comfortable and confident in its use, reducing the risk of accidents. Additionally, standardization ensures that all equipment meets safety standards and is properly maintained, further minimizing the potential for workplace injuries.

3. Improved Equipment Maintenance

Maintaining a variety of different equipment types can be challenging and time-consuming. With MHE standardization, companies can simplify equipment maintenance by focusing on a smaller set of standardized tools. This allows for easier access to spare parts, reduces maintenance costs, and simplifies the training of maintenance personnel.

4. Cost Savings

Standardizing MHE can lead to significant cost savings. By using the same equipment throughout the warehouse, companies can benefit from bulk purchasing discounts and economies of scale. Additionally, standardized equipment requires less training, reducing onboarding costs for new employees. Furthermore, by reducing the risk of accidents and improving efficiency, companies can minimize costly downtime and improve overall cost-effectiveness.

At HCO Innovations, we understand the importance of MHE standardization in warehouse optimization. As a leading provider of warehouse optimization solutions, including MHE management, we have helped numerous businesses achieve their operational goals.

Our Material Handling Equipment Management solution enables companies to optimize their MHE fleet, develop standardized procedures, and implement best practices for maintenance and safety. With our expertise and industry-leading software, businesses can unlock the potential of their warehouses and drive significant improvements in productivity and cost-effectiveness.

Your warehouse operations deserve the best. Contact HCO Innovations today to learn more about our MHE standardization solutions and how we can help transform your warehouse into a highly efficient and profitable operation.