Warehouse safety is a top priority for every business. With the countless activities and heavy machinery involved in warehouse operations, it is crucial to ensure the well-being of employees and the protection of valuable inventory. One effective way to enhance safety in warehouses is through the use of safety barriers and guardrails.

The Importance of Safety Barriers

Safety barriers are designed to create a physical separation between different areas within a warehouse. They serve as a protective barrier, preventing unauthorized access to restricted areas and reducing the risk of accidents.

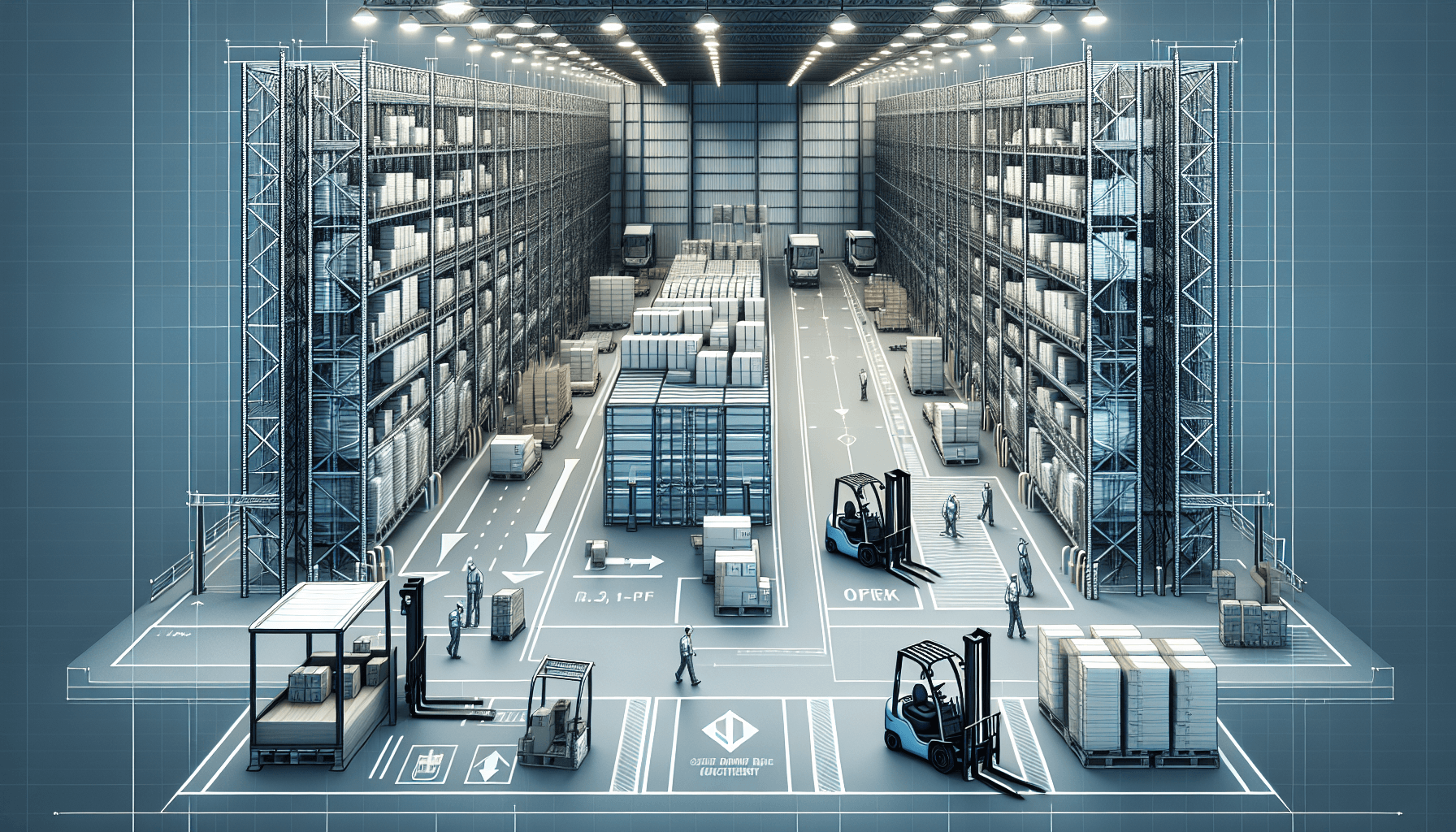

One of the key benefits of safety barriers is the prevention of collisions. In a busy warehouse environment, forklifts and other machinery are constantly in motion. Safety barriers help to create dedicated pathways for these vehicles, separating them from pedestrian walkways and other work areas. By clearly marking out these paths and preventing obstructions, safety barriers significantly reduce the chances of collisions and injuries.

Besides preventing accidents, safety barriers also play a vital role in improving the flow of operations within a warehouse. By delineating specific areas for different activities, such as loading and unloading zones or storage areas, safety barriers help to optimize the use of space and ensure efficient workflow. This prevents confusion and congestion, leading to increased productivity and reduced downtime.

Another key benefit of safety barriers is their ability to provide visual cues and reminders about safety protocols. For example, in areas where potentially hazardous materials are stored, safety barriers can be used to clearly mark the boundaries and remind employees to take caution. This promotes a safety-conscious culture within the warehouse and helps to prevent accidents and injuries.

The Advantages of Guardrails

In addition to safety barriers, guardrails are another essential component of warehouse safety. Guardrails are typically installed along elevated platforms, mezzanines, and loading docks to prevent falls and provide a protective barrier.

One of the main advantages of guardrails is their ability to prevent falls from heights. In a warehouse environment, there are often elevated areas where employees need to work, such as elevated platforms for inventory maintenance or loading docks for shipment operations. Guardrails provide a physical barrier that prevents accidental falls, protecting employees from severe injuries and even fatalities.

Guardrails also serve as a visual and physical reminder of potential hazards. By clearly marking out the edges of elevated areas, guardrails help to create a safe working environment and reduce the risk of falls. They act as a constant reminder for employees to stay within the safe zone and take necessary precautions.

Furthermore, guardrails can be equipped with additional safety features such as toe boards and midrails. Toe boards prevent items from falling off elevated platforms, reducing the risk of inventory damage and potential injuries to employees below. Midrails provide an additional barrier between the top rail of the guardrail and the ground, ensuring enhanced safety and stability.

The Overall Benefits

By investing in safety barriers and guardrails, warehouses can enjoy a multitude of benefits. Some of these benefits include:

- Improved safety for employees: Safety barriers and guardrails create a physical separation between different areas, minimizing the risk of collisions and falls.

- Reduced risk of product damage: Safety barriers prevent accidents and collisions, reducing the chances of product damage.

- Increased productivity: Well-designed safety barriers optimize workflow, preventing congestion and allowing for smooth operations.

- Enhanced compliance: Safety barriers and guardrails help warehouses comply with safety standards and regulations, avoiding potential penalties.

To ensure the safety of your warehouse operations, it is essential to assess your current safety measures and consider implementing safety barriers and guardrails. HCO Innovations offers comprehensive warehouse safety evaluations to identify potential risks and provide tailored solutions to enhance safety. Click here to learn more about their warehouse safety evaluation services.

Remember, a safe warehouse is a productive warehouse. Prioritizing safety through the use of safety barriers and guardrails not only protects your employees but also improves operational efficiency and minimizes costly accidents. Invest in warehouse safety today and reap the benefits for years to come.