Warehouse operations can be complex and fast-paced, with various activities happening simultaneously. Ensuring the safety of workers should be a top priority for any organization. One effective way to improve safety measures is through regular warehouse pedestrian safety audits. By conducting these audits, companies can identify potential hazards, assess current safety protocols, and implement necessary improvements.

Why are Warehouse Pedestrian Safety Audits Important?

Warehouse pedestrian safety audits are crucial for a number of reasons. First and foremost, they help prevent accidents and injuries. According to the Occupational Safety and Health Administration (OSHA), forklift accidents alone account for approximately 100,000 injuries each year in the United States. By identifying potential hazards and implementing necessary safety measures, companies can significantly reduce the risk of such accidents and create a safer working environment for their employees.

Furthermore, regular safety audits can help organizations comply with safety regulations and standards. OSHA and other regulatory bodies have established guidelines to ensure the safety of workers in warehouse environments. By conducting safety audits, companies can identify areas where they may be falling short of these standards and take appropriate corrective measures to ensure compliance.

Another advantage of warehouse pedestrian safety audits is that they can improve overall productivity and efficiency. When workers feel safe and confident in their workplace, they are more likely to be productive and efficient. By eliminating potential hazards and implementing safety measures, companies can create an environment that promotes productivity and reduces downtime due to accidents or injuries.

The Key Benefits of Warehouse Pedestrian Safety Audits

1. Hazard Identification and Prevention:

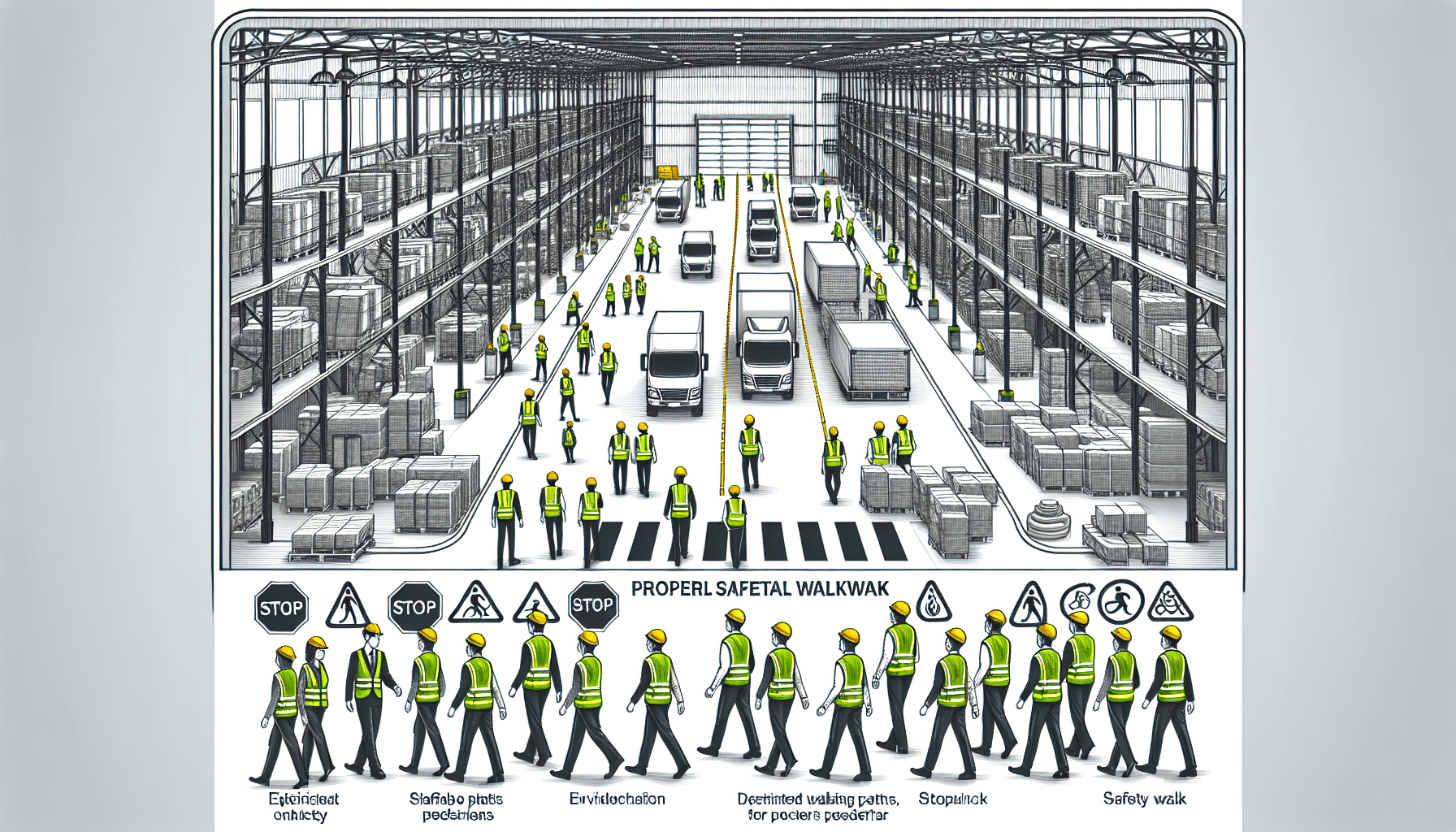

One of the primary goals of warehouse pedestrian safety audits is to identify potential hazards and prevent accidents. Audits enable companies to identify hazards such as poor lighting, obstructed pathways, or inadequate signage. By addressing these issues promptly, organizations can significantly reduce the risk of accidents and injuries.

2. Improved Safety Protocols:

Safety audits provide companies with an opportunity to review and improve their existing safety protocols. This includes assessing the effectiveness of safety training programs, ensuring the proper use of personal protective equipment (PPE), and evaluating the efficiency of emergency response procedures. By identifying areas for improvement, companies can enhance their safety protocols and better protect their employees.

3. Increased Awareness and Engagement:

Warehouse pedestrian safety audits promote a culture of safety and increased awareness among employees. When workers see that their company is actively conducting audits and taking steps to improve safety, they feel valued and empowered. This can lead to increased employee engagement and a proactive attitude towards safety.

4. Cost Savings:

Investing in warehouse pedestrian safety audits can result in long-term cost savings for companies. By preventing accidents and injuries, organizations can reduce worker’s compensation claims and associated medical expenses. In addition, improved safety measures can help minimize property damage caused by accidents, leading to potential insurance savings.

5. Compliance with Regulations:

Warehouse operations must comply with various safety regulations, including those set by OSHA. Regular safety audits ensure that companies meet these requirements, avoiding potential fines or penalties. Compliance with safety regulations also helps maintain a positive reputation and credibility in the industry.

6. Integration of Technology:

Warehouse pedestrian safety audits provide companies with an opportunity to evaluate and integrate advanced safety technologies. For example, implementing a forklift pedestrian detection system can significantly enhance safety in warehouse environments. These systems use sensors and alarms to detect the presence of pedestrians near forklifts, preventing potential accidents. By identifying the need for such technologies during safety audits, companies can leverage innovative solutions to further improve safety.

Implementing Warehouse Pedestrian Safety Audits

To implement effective warehouse pedestrian safety audits, companies should follow a systematic approach. This includes:

- Assigning a dedicated safety team responsible for conducting the audits and implementing necessary improvements.

- Developing a checklist or audit plan that covers all relevant safety aspects, including layout and organization, signage and markings, lighting, emergency procedures, and training programs.

- Conducting regular safety audits, preferably on a quarterly or bi-annual basis, to ensure ongoing compliance and continuous improvement.

- Documenting audit findings and actions taken to address any identified hazards or areas for improvement.

- Providing regular training and education to employees to raise awareness about safety protocols and encourage their active participation in maintaining a safe workplace.

In conclusion, warehouse pedestrian safety audits are essential for organizations seeking to enhance safety, productivity, and compliance within their warehouse operations. By identifying hazards, improving safety protocols, and integrating technology where necessary, companies can create a safer working environment while also benefiting from increased efficiency and reduced costs.

If you are interested in learning more about warehouse safety solutions, particularly forklift pedestrian detection systems, visit HCO Innovations.

What is a warehouse pedestrian safety audit?

A warehouse pedestrian safety audit is a comprehensive assessment of the safety measures and practices in place to protect pedestrians, such as workers and visitors, within a warehouse or industrial facility. It involves evaluating the layout, equipment, signage, and policies to identify any potential hazards and make recommendations for improvement.

Why are warehouse pedestrian safety audits important?

Warehouse pedestrian safety audits are important because they help prevent accidents and injuries within the facility. By identifying and addressing potential hazards, such as poorly marked walkways or inadequate training, audits can significantly reduce the risk of accidents involving pedestrians. This can lead to a safer work environment and lower insurance costs.

Who should conduct warehouse pedestrian safety audits?

Warehouse pedestrian safety audits should ideally be conducted by trained safety professionals or consultants who have expertise in warehouse operations and safety regulations. They have the knowledge and experience to thoroughly assess the facility and recommend appropriate safety measures.

How often should warehouse pedestrian safety audits be conducted?

The frequency of warehouse pedestrian safety audits can vary depending on factors such as the size of the facility, the nature of operations, and any recent incidents. However, it is generally recommended to conduct audits at least once a year. Regular audits help ensure that safety measures are kept up to date and any new risks are promptly identified and addressed.

What are some common findings in warehouse pedestrian safety audits?

Common findings in warehouse pedestrian safety audits include inadequate signage, poor visibility, lack of designated walkways, insufficient training, and inadequate maintenance of equipment. These findings highlight potential areas for improvement to enhance pedestrian safety.

How can warehouse pedestrian safety audits benefit a business?

Warehouse pedestrian safety audits can benefit a business in numerous ways. By proactively addressing safety concerns, businesses can reduce the risk of accidents and injuries, leading to a more productive workforce and decreased downtime. Additionally, audits help businesses comply with safety regulations, avoid fines or penalties, and improve their overall reputation.

Are there any legal requirements for conducting warehouse pedestrian safety audits?

While specific legal requirements for conducting warehouse pedestrian safety audits may vary depending on the jurisdiction and industry, many countries have specific regulations or guidelines in place regarding workplace safety. It is important for businesses to familiarize themselves with these regulations and ensure compliance through regular safety audits.

Can warehouse pedestrian safety audits help reduce insurance costs?

Yes, conducting regular warehouse pedestrian safety audits can help reduce insurance costs. By demonstrating a proactive approach to safety and implementing recommended safety measures, businesses can lower the risk of accidents and injuries, which can lead to lower insurance premiums.

The Importance of Regular Equipment Maintenance in Warehouses.

Regular equipment maintenance is crucial for the smooth and efficient functioning of any warehouse. As a leading management consulting firm specializing in warehouse optimization and forklift fleet management, HCO Innovations understands the significant impact that regular maintenance can have on warehouse operations. With their expertise and comprehensive services, they help businesses achieve optimal performance and cost reductions.

The Benefits of Regular Equipment Maintenance

Proper and regular maintenance of warehouse equipment, such as forklifts, conveyor systems, and packaging machines, is essential for several reasons:

- Increased Equipment Lifespan: Regular maintenance helps to prolong the lifespan of your equipment. By identifying and addressing potential issues early on, you can prevent major breakdowns and extend the life of your machinery, saving you from the costly need for premature replacements.

- Improved Safety: Equipment malfunctions can pose serious safety hazards to warehouse employees. Regular maintenance ensures that all safety mechanisms are properly functioning, reducing the risk of accidents and injuries. HCO Innovations prioritizes safety assessments as part of their comprehensive services, providing businesses with peace of mind.

- Enhanced Efficiency and Productivity: Well-maintained equipment operates at optimal levels, resulting in improved efficiency and productivity. Regular maintenance includes cleaning, lubrication, and calibration of equipment, ensuring smooth operation and minimizing downtime. HCO Innovations can help businesses evaluate their warehouse layout to optimize workflow and maximize efficiency.

- Cost Savings: Regular maintenance not only reduces the risk of major breakdowns but also minimizes the need for costly repairs. Additionally, well-maintained equipment consumes less energy and experiences fewer performance issues, resulting in lower utility and maintenance costs. By partnering with HCO Innovations, businesses can benefit from their turnkey maintenance solutions and advanced cost-tracking software to achieve significant cost savings.

Given the importance of regular equipment maintenance, it is crucial to develop a robust maintenance plan for your warehouse. This plan should include scheduled inspections, preventive maintenance tasks, and a comprehensive record-keeping system that tracks maintenance activities and identifies any recurring issues.

Partnering with a trusted consulting firm like HCO Innovations can provide you with the expertise and resources needed to develop and implement an effective maintenance plan. Their collaborative approach and "boots on the ground" methodology ensure that all aspects of your warehouse operations are thoroughly evaluated.

HCO Innovations leverages cutting-edge technology to track and monitor the performance of your equipment and offers tailored solutions to address your specific needs. Whether you are in the distribution, manufacturing, or food processing industry, their team of experts can help you achieve significant cost reductions and operational efficiency.

Implementing regular maintenance not only ensures the proper functioning of your equipment but also creates a culture of proactive care within your organization. When employees understand the importance of maintenance and their role in keeping equipment in optimal condition, they can contribute to a safer and more efficient work environment.

In conclusion, regular equipment maintenance is vital for warehouse optimization and reducing material handling costs. Partnering with a consulting firm like HCO Innovations can provide you with the necessary expertise and turnkey solutions to achieve significant cost savings and operational efficiency. Emphasizing regular maintenance not only extends the lifespan of your equipment but also enhances safety, improves efficiency and productivity, and leads to long-term cost savings. Don't underestimate the impact that regular maintenance can have on your warehouse operations. Take proactive steps today to ensure the smooth running of your equipment and overall warehouse performance.

To learn more about HCO Innovations and how they can help optimize your warehouse operations, visit HCO Innovations.