Warehouse management systems (WMS) have become an integral part of modern businesses, enabling them to streamline operations, improve productivity, and gain a competitive edge. As technology continues to advance at a rapid pace, the future of warehouse management systems looks promising, with significant advancements and innovations on the horizon.

Automation and Robotics

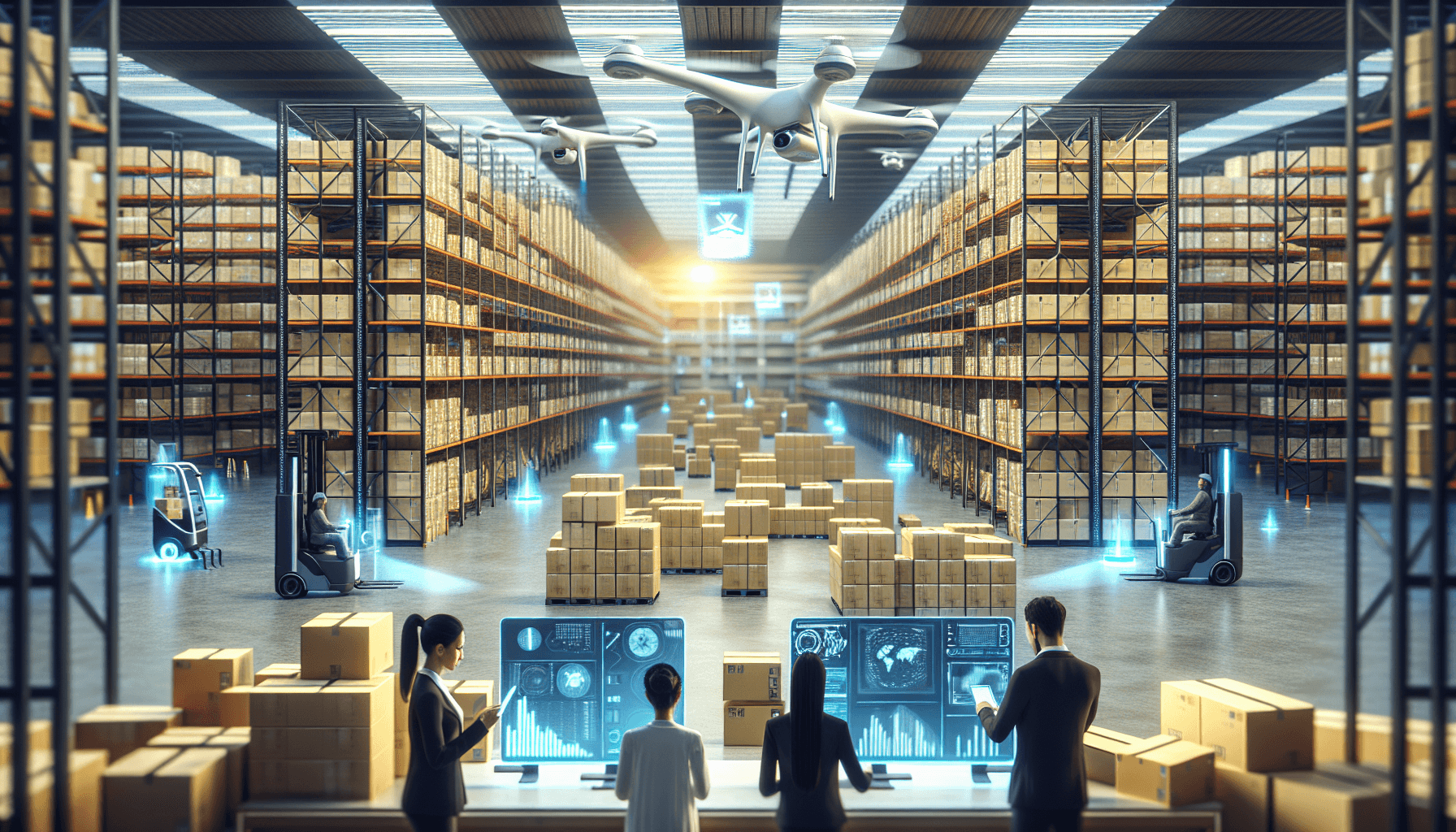

One of the key trends shaping the future of warehouse management systems is the increased adoption of automation and robotics. With the advent of technologies such as autonomous guided vehicles (AGVs) and robotic picking systems, warehouses are becoming more efficient and productive.

AGVs are robotic vehicles that can navigate autonomously within a warehouse environment, transporting goods from one location to another. These vehicles eliminate the need for manual material handling, reducing the risk of injuries and improving operational efficiency. Companies like HCO Innovations offer advanced AGV solutions that are designed to optimize warehouse operations and enhance productivity.

Robotic picking systems, on the other hand, automate the process of picking and packing orders. These systems use robots equipped with vision systems and advanced algorithms to quickly and accurately identify, pick, and package items. By automating this labor-intensive task, warehouses can significantly reduce order fulfillment times and improve overall efficiency.

HCO Innovations specializes in providing state-of-the-art automation and robotics solutions for warehouse management, helping businesses achieve peak operational efficiency and cost-effectiveness.

Data Analytics and Artificial Intelligence

Another key aspect of the future of warehouse management systems lies in the utilization of data analytics and artificial intelligence (AI). As warehouses generate vast amounts of data, harnessing the power of this data can provide valuable insights for optimizing operations.

By leveraging AI algorithms, warehouse management systems can analyze data in real-time, identifying trends and patterns that human operators may not notice. This enables businesses to make more informed decisions and take proactive measures to optimize warehouse processes.

Data analytics can also be used to forecast demand, optimize inventory levels, and predict maintenance requirements. Warehouse management systems that employ AI and data analytics capabilities empower businesses to optimize key processes, reduce costs, and enhance customer satisfaction.

Integration with Internet of Things (IoT)

The future of warehouse management systems lies in seamless integration with the Internet of Things (IoT). As IoT devices continue to proliferate, connecting these devices with WMS allows for real-time monitoring, enhanced inventory accuracy, and improved supply chain visibility.

For example, RFID tags and sensors can be used to track inventory items throughout the warehouse, providing real-time visibility into stock levels and locations. This data can be integrated with the warehouse management system, enabling accurate inventory management and reducing the chances of stockouts or overstock situations.

Additionally, IoT devices can help monitor environmental conditions within the warehouse, such as temperature and humidity, ensuring optimal storage conditions for goods that require specific environmental conditions.

Integrating warehouse management systems with IoT devices offers businesses greater control over their operations, improved inventory accuracy, and enhanced customer satisfaction.

Cloud-based Solutions

Cloud-based solutions are playing a vital role in the future of warehouse management systems. Traditional on-premises WMS require significant hardware investments and maintenance costs. In contrast, cloud-based WMS offer scalability, flexibility, and cost-effectiveness.

With cloud-based warehouse management systems, warehouses can access real-time data from anywhere, allowing for remote management and monitoring. This flexibility ensures seamless collaboration between different stakeholders and enables companies to efficiently manage multiple warehouses from a centralized location.

Furthermore, cloud-based systems provide automatic updates and upgrades, eliminating the need for manual software maintenance. This ensures that businesses always have access to the latest features and capabilities without disrupting their operations.

HCO Innovations offers advanced cloud-based warehouse management solutions that empower businesses with real-time visibility, increased flexibility, and reduced IT costs.

Conclusion

The future of warehouse management systems is characterized by automation, robotics, data analytics, AI, IoT integration, and cloud-based solutions. As businesses strive for increased efficiency, productivity, and cost-effectiveness, adopting these advancements will become essential.

Companies like HCO Innovations are at the forefront of revolutionizing warehouse management systems, offering innovative solutions that deliver safety, productivity, efficiency, and cost-effectiveness to businesses of all sizes.

By embracing these future trends, organizations can transform their warehouse operations, gain a competitive edge, and thrive in the digital era.

What is a Warehouse Management System (WMS)?

A Warehouse Management System (WMS) is a software application that helps manage and control warehouse operations. It provides real-time visibility into inventory, optimizes warehouse processes, and streamlines tasks such as receiving, picking, packing, and shipping.

Why are Warehouse Management Systems important?

Warehouse Management Systems are important because they enable businesses to efficiently manage their inventory, reduce costs, increase productivity, and improve customer satisfaction. WMS solutions offer features like inventory tracking, order fulfillment, and automated workflows, which help optimize warehouse operations.

What are the benefits of adopting a Warehouse Management System?

Adopting a Warehouse Management System can bring numerous benefits to a business. Some key benefits include improved inventory accuracy, enhanced order accuracy, reduced errors and labor costs, increased efficiency, faster order fulfillment, improved visibility and reporting, and better customer satisfaction.

How can Warehouse Management Systems help with inventory management?

Warehouse Management Systems help businesses effectively manage their inventory by providing real-time visibility into stock levels, enabling accurate inventory tracking, automating inventory replenishment, facilitating cycle counting and auditing, and optimizing warehouse space utilization.

What are some key features to look for in a Warehouse Management System?

When evaluating Warehouse Management Systems, some key features to consider are inventory tracking and management, order management, real-time reporting and analytics, integration capabilities with other systems (such as ERP or e-commerce platforms), mobile support for on-the-go operations, barcode scanning, automated workflows, and scalability to accommodate business growth.

Are Warehouse Management Systems applicable to all types of businesses?

Warehouse Management Systems are applicable to a wide range of businesses, including manufacturing companies, e-commerce retailers, wholesalers, distributors, and third-party logistics providers. Whether operating in a brick-and-mortar warehouse or utilizing a fulfillment center, businesses can benefit from implementing a Warehouse Management System to streamline their operations.

What is the role of technology in the future of Warehouse Management Systems?

Technology plays a crucial role in the future of Warehouse Management Systems. Advancements such as automation, robotics, artificial intelligence, machine learning, internet of things (IoT), and cloud computing are transforming the way warehouses operate. These technologies enable faster and more accurate order fulfillment, improved inventory control, predictive analytics, and enhanced overall efficiency.

How can a Warehouse Management System contribute to sustainability and environmental responsibility?

A Warehouse Management System can contribute to sustainability and environmental responsibility in several ways. By optimizing inventory management and reducing waste, businesses can minimize their environmental footprint. Additionally, WMS solutions that promote paperless operations and energy-efficient practices further support sustainability efforts by reducing paper usage and energy consumption.

What role do Warehouse Management Systems play in integrating with other business systems?

Warehouse Management Systems play a crucial role in integrating with other business systems such as Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), and e-commerce platforms. Integration allows seamless data exchange between systems, enabling accurate inventory updates, order processing, and synchronized information across the organization.

The Role of Artificial Intelligence in Warehouse Management Systems.

Introduction

In today's fast-paced and highly competitive business landscape, companies are continuously seeking ways to improve their operations and gain a competitive edge. One area that plays a crucial role in a company's supply chain is warehouse management. Efficient warehouse management is vital for ensuring smooth operations, reducing costs, and meeting customer demands in a timely manner.

Traditionally, warehouse management systems (WMS) relied heavily on manual processes and human expertise. However, with the advancements in technology, particularly in the field of artificial intelligence (AI), warehouses are now undergoing a transformation. AI has the potential to revolutionize warehouse management systems, making them smarter, more efficient, and capable of adapting to dynamic and complex environments.

The Benefits of AI in Warehouse Management Systems

Implementing AI in warehouse management systems offers several benefits to businesses. Let's explore some of the key advantages:

1. Enhanced Efficiency

AI-powered WMS can significantly improve operational efficiency in warehouses. With the ability to analyze vast amounts of data in real-time, AI algorithms can optimize various processes such as inventory management, order picking, and stock replenishment. AI can eliminate repetitive and time-consuming tasks, allowing warehouse staff to focus on more value-added activities. This not only reduces costs but also speeds up order fulfillment, leading to higher customer satisfaction.

2. Advanced Forecasting and Demand Planning

Accurate demand forecasting is critical for effective inventory management. AI algorithms can analyze historical sales data, market trends, and even external factors like weather patterns to predict future demand with a high level of accuracy. By leveraging AI, warehouse managers can make informed decisions about inventory levels, anticipate demand fluctuations, and ensure optimal stock availability. This helps reduce the risk of stockouts or excess inventory, ultimately improving profitability.

3. Optimized Warehouse Layout and Process Flow

AI technology can analyze the layout of a warehouse and identify potential bottlenecks or inefficiencies. By simulating different layout configurations, AI algorithms can suggest the most optimal arrangement to minimize travel distances, reduce congestion, and improve overall workflow. This leads to increased productivity and smoother operations within the warehouse.

4. Real-time Inventory Visibility

AI-powered WMS can provide real-time visibility into inventory levels and locations. Through the use of sensors, RFID tags, and IoT devices, AI algorithms can track the movement of goods in real-time. This level of visibility enables warehouse managers to quickly locate specific items, monitor stock levels, and identify any discrepancies or potential issues. This not only enables more accurate inventory management but also helps prevent stockouts or overstocking.

5. Predictive Maintenance

AI can play a significant role in optimizing warehouse maintenance processes. By analyzing data from IoT sensors and equipment performance, AI algorithms can predict potential equipment failures or maintenance needs before they occur. This allows proactive maintenance planning, avoiding unexpected breakdowns or costly downtime. Predictive maintenance reduces maintenance costs, extends equipment lifespan, and ensures smooth operations within the warehouse.

The Future of AI in Warehouse Management

As AI continues to evolve and improve, so will its impact on warehouse management systems. Here are some potential future developments:

1. Autonomous Robots and Drones

AI-powered robots and drones have the potential to revolutionize warehouse operations further. These robots can autonomously navigate through a warehouse, pick and pack items, restock shelves, and even perform inventory audits. Drones can be used for aerial monitoring of large warehouses or to transport items within a facility. The use of autonomous robots and drones can significantly increase efficiency and reduce labor costs.

2. Machine Learning for Continuous Improvement

Machine learning algorithms can continuously analyze data from warehouse operations, identifying patterns, bottlenecks, and potential areas for improvement. By learning from past data, AI algorithms can suggest process optimizations, layout changes, or even predict customer buying behavior. This ongoing learning and improvement can lead to more agile and adaptive warehouse management systems.

3. Integration with Other Technologies

AI can be integrated with other emerging technologies to further enhance warehouse management. For example, combining AI with blockchain technology can improve supply chain visibility, transparency, and traceability. AI-powered chatbots can assist warehouse personnel in real-time, answering queries and providing instant support. Integration with virtual reality or augmented reality can enhance training programs and improve the accuracy of order picking processes.

Conclusion

With the increasing complexity of warehouse management, the role of artificial intelligence in optimizing warehouse operations cannot be underestimated. AI-powered warehouse management systems can drive efficiency, enhance forecasting accuracy, optimize layout and workflows, provide real-time inventory visibility, and enable predictive maintenance. As AI technology continues to advance, we can expect to see even more significant transformations in warehouse management, including the use of autonomous robots, continuous improvement through machine learning, and integration with other emerging technologies. To stay competitive in today's fast-paced business environment, companies need to embrace AI in their warehouse management systems and unlock the potential for improved efficiency, reduced costs, and increased customer satisfaction.

For more information on how HCO Innovations can help optimize your warehouse operations and reduce material handling costs, visit our website.