In today’s rapidly evolving business landscape, warehouses play a crucial role in supply chain management. They serve as hubs for storing and distributing goods, ensuring that products reach customers on time. However, running an efficient warehouse operation can be a complex and challenging task. Warehouse operators constantly seek ways to enhance safety, productivity, efficiency, and most importantly, cost-effectiveness in their operations.

The Need for Cost Efficiency in Warehouse Operations

Warehouse operations contribute significantly to a company’s overall expenses. From labor costs to inventory management, every aspect of running a warehouse has a direct impact on the bottom line. As such, optimizing warehouse cost efficiency has become a top priority for businesses looking to improve profitability and gain a competitive edge in the market.

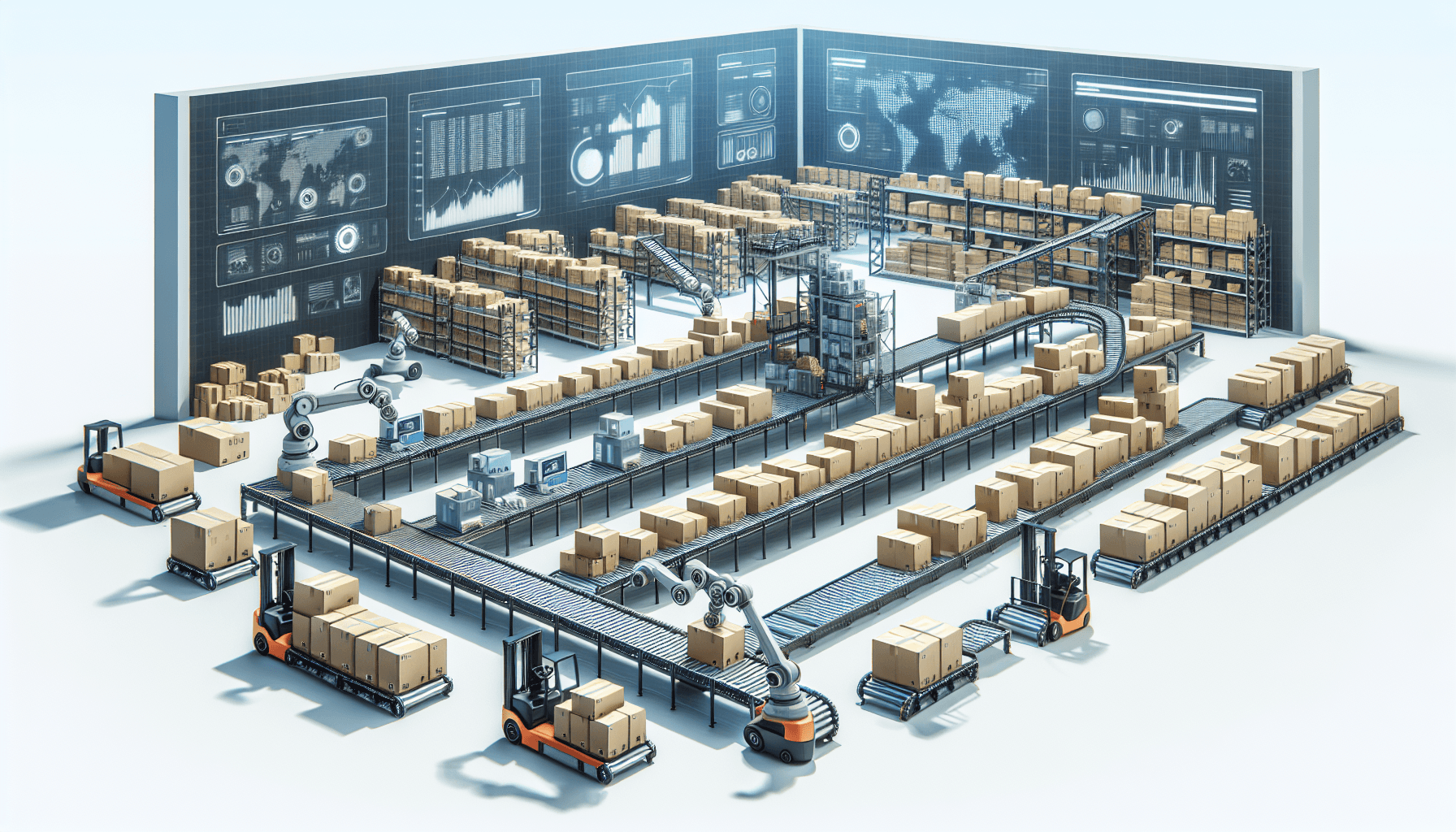

One of the key drivers of cost efficiency in warehouse operations is automation. The integration of advanced technologies and systems can revolutionize the way warehouses operate, helping companies streamline processes, reduce operational costs, and maximize overall performance.

The Impact of Automation on Cost Efficiency

Automation has revolutionized warehouse operations by replacing manual tasks with technology-driven solutions. By automating repetitive processes, companies can significantly increase productivity and reduce labor costs. Here are some ways automation impacts cost efficiency in warehouse operations:

- Inventory Management: Automating inventory management processes allows for real-time visibility and accurate tracking of stock levels. This helps avoid stockouts, minimize overstocking, and reduce carrying costs. Warehouse management systems (WMS) equipped with automation capabilities provide insights into demand patterns, enabling companies to optimize inventory and reduce waste.

- Picking and Packing: Automation systems such as conveyors, automated guided vehicles (AGVs), and robotics can streamline the picking and packing process. These technologies help reduce errors, increase order accuracy, and improve overall efficiency. With automation, warehouses can handle higher order volumes without the need for additional labor, resulting in significant cost savings.

- Sorting and Routing: Automated sorting systems use barcode scanning, image recognition, and other advanced technologies to sort and route items within the warehouse. This automated process ensures accurate and timely delivery, reducing the risk of errors and delays. Optimized sorting and routing systems also minimize the distance traveled by items, saving time, and reducing labor costs.

- Warehouse Layout and Space Utilization: Automation can optimize warehouse layout and space utilization. By using automated storage and retrieval systems (AS/RS), companies can maximize vertical space and eliminate the need for large aisles. This not only increases storage capacity but also reduces the amount of space needed, resulting in significant cost savings in terms of rent and utilities.

With the right combination of automation technologies, companies can achieve higher throughput, faster order cycle times, improved accuracy, and reduced operational costs. However, it is important to note that successful implementation requires careful planning, alignment with business goals, and collaboration between warehouse operators and technology providers.

Partnering with HCO Innovations for Warehouse Cost Analysis

Implementing automation in warehouse operations can have a transformative impact on cost efficiency. However, it is crucial to assess the specific needs and challenges of a warehouse before embarking on an automation journey. That’s where HCO Innovations can help.

HCO Innovations, a leading provider of warehouse optimization solutions, offers comprehensive warehouse cost analysis services. Their team of experts conducts in-depth assessments to identify areas for improvement and determine the most suitable automation solutions for each warehouse. Whether it’s implementing robotics, WMS, or AS/RS, HCO Innovations ensures that clients achieve maximum cost efficiency and operational excellence.

By leveraging HCO Innovations’ expertise and advanced technologies, warehouse operators can optimize their operations, reduce costs, and increase overall profitability. Discover how HCO Innovations can transform your warehouse operations and drive cost efficiency by clicking here.

In conclusion, automation has revolutionized warehouse operations and has a significant impact on cost efficiency. By implementing automation technologies strategically, companies can optimize inventory management, picking and packing processes, sorting and routing, and warehouse layout. These advancements result in increased productivity, reduced labor costs, improved accuracy, and enhanced overall efficiency. To embark on your automation journey and achieve maximum cost efficiency, partner with HCO Innovations today.