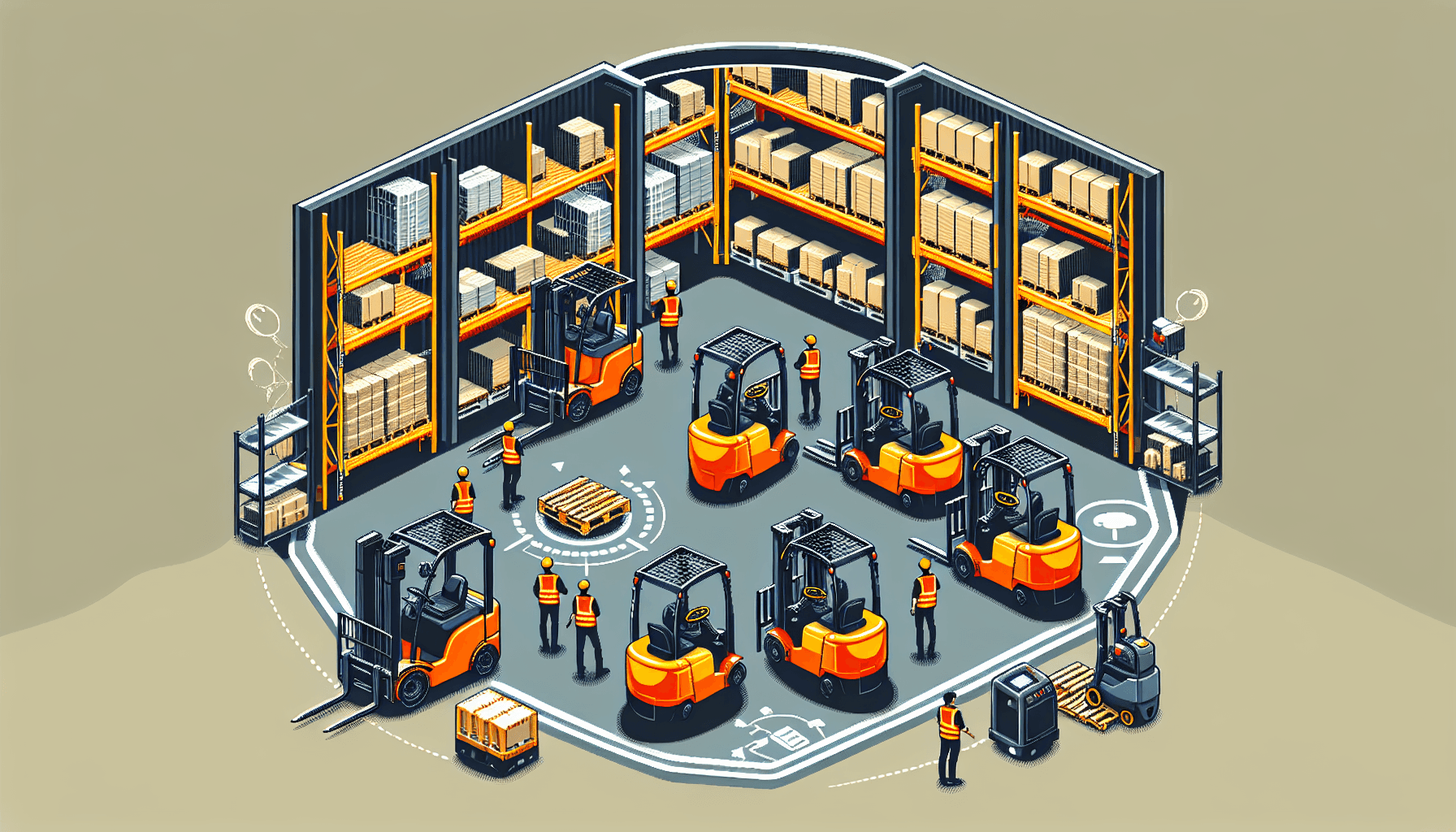

Forklift fleet management plays a crucial role in optimizing warehouse efficiency. As a warehouse manager or operator, it’s important to recognize the impact that effective fleet management can have on your operations. By implementing proper strategies and utilizing advanced technologies, you can streamline your warehouse processes, enhance productivity, and ultimately improve your bottom line. In this article, we will explore the various ways in which forklift fleet management can positively influence warehouse efficiency.

The Importance of Forklift Fleet Management

Forklifts are an essential part of warehouse operations, enabling the movement and transportation of goods in a quick and efficient manner. However, managing a fleet of forklifts can be a complex task without the right systems in place. This is where forklift fleet management comes into play.

At its core, forklift fleet management involves the effective utilization, maintenance, and monitoring of the forklifts within a warehouse. It encompasses various strategies and technologies aimed at optimizing the performance and lifespan of the forklifts, as well as ensuring the safety of warehouse personnel. By implementing a comprehensive forklift fleet management system, warehouse operators can achieve significant improvements in efficiency and productivity.

Benefits of Effective Forklift Fleet Management

Effective forklift fleet management offers a multitude of benefits for warehouse operations. Let’s take a closer look at some of these key advantages:

- Improved Productivity: Properly managed forklift fleets allow for better utilization of these essential tools. With a well-organized fleet, operators can ensure that forklifts are readily available when needed, minimizing downtime and maximizing productivity.

- Enhanced Safety: Forklifts can be hazardous if not operated and maintained properly. Implementing a comprehensive fleet management system helps enforce safety protocols, such as regular maintenance checks, operator training, and monitoring of forklift usage. This contributes to a safer work environment and reduces the risk of accidents and injuries.

- Optimized Maintenance: Forklifts require regular maintenance to ensure their optimal performance. Fleet management systems help track maintenance schedules, allowing operators to schedule maintenance tasks proactively. This prevents unexpected breakdowns and reduces the need for costly repairs, ultimately saving time and money.

- Data-driven Decision Making: Advanced forklift fleet management solutions provide real-time data and analytics on fleet performance. Operators can track key metrics such as utilization rates, fuel consumption, and maintenance costs. This data empowers them to make informed decisions, identify areas for improvement, and implement strategies to enhance warehouse efficiency.

The Role of Technology in Forklift Fleet Management

Technology plays a pivotal role in optimizing forklift fleet management. Various innovative solutions have emerged to simplify fleet management operations and improve overall efficiency. Some of the key technologies utilized in forklift fleet management include:

- Telematics: Telematics systems use GPS and onboard sensors to collect data on forklift operations. This data includes information on forklift location, usage patterns, and performance metrics. By analyzing this data, operators can identify inefficiencies, optimize routes, and improve overall fleet performance.

- Asset Tracking: RFID (Radio Frequency Identification) and barcode technologies enable real-time tracking of forklifts within the warehouse. This ensures accurate inventory management, reduces the chance of loss or theft, and enhances overall logistics operations.

- Maintenance Management Systems: These systems help streamline maintenance activities by automating tasks such as scheduling inspections, generating work orders, and tracking maintenance history. By implementing such systems, warehouse operators can ensure that forklifts receive timely maintenance, reducing the risk of breakdowns and improving overall operational efficiency.

- Training Simulators: Virtual reality (VR) training simulators provide a safe environment for forklift operators to practice their skills. Simulators allow operators to learn and refine their techniques without the risk of accidents or damage to equipment. This improves operator proficiency and enhances overall warehouse safety and efficiency.

In conclusion, forklift fleet management plays a vital role in optimizing warehouse efficiency. By implementing effective fleet management strategies and utilizing advanced technologies, warehouse operators can enhance productivity, streamline operations, and improve overall cost-effectiveness. To learn more about the importance of forklift fleet management and how it can transform your warehouse operations, visit HCO Innovations.