When it comes to warehouse operations, optimal performance is crucial for businesses to stay competitive and maximize their profitability. One essential aspect of warehouse operations is the management of the forklift fleet. Forklifts play a vital role in material handling and logistics within the warehouse, and their performance directly impacts overall efficiency and cost-effectiveness.

The Importance of Forklift Fleet Performance Metrics

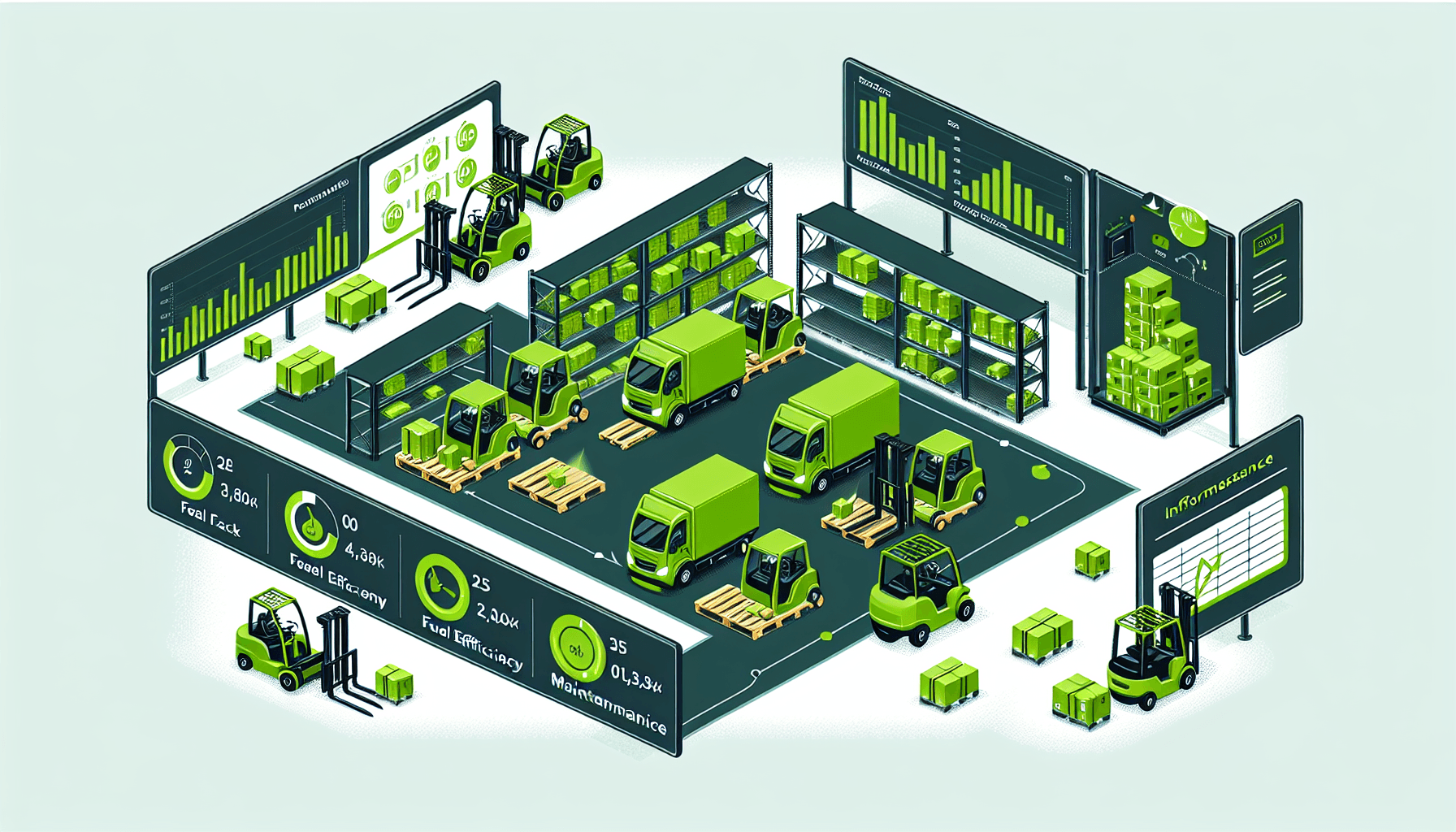

By monitoring and analyzing forklift fleet performance metrics, warehouse managers can identify areas for improvement, make informed decisions, and implement effective strategies to optimize their operations. These performance metrics provide valuable insights into the productivity, safety, and maintenance requirements of the forklift fleet.

One of the key benefits of tracking forklift fleet performance metrics is the ability to identify and address inefficiencies. With accurate data on metrics such as productivity, utilization, and downtimes, warehouse managers can identify bottlenecks, reduce idle time, and increase throughput. This optimization of operations leads to improved overall efficiency and productivity.

Another important aspect of monitoring forklift fleet performance metrics is safety. Forklift operations can be hazardous if not properly managed. By tracking metrics related to safety incidents, near misses, and operator compliance, warehouse managers can identify areas of concern and take proactive measures to address them. This helps create a safer working environment for employees, minimizing the risk of accidents and injuries.

Furthermore, monitoring forklift fleet performance metrics helps businesses achieve cost savings. By analyzing metrics such as fuel consumption, maintenance costs, and equipment utilization, warehouse managers can identify opportunities to reduce expenses. For example, if certain forklifts consistently require more maintenance, it may indicate the need for preventive maintenance or replacement. This proactive approach can save costs in the long run by preventing breakdowns and expensive repairs.

In addition to cost savings, optimizing forklift fleet performance also contributes to environmental sustainability. By monitoring metrics such as fuel consumption and emissions, warehouse managers can identify opportunities to reduce carbon footprint and promote eco-friendly practices. For instance, by replacing older forklift models with newer, energy-efficient ones, businesses can minimize their environmental impact while also reducing fuel costs.

One effective way to track and manage forklift fleet performance metrics is through the use of advanced fleet management systems. These systems collect real-time data on various metrics, such as vehicle utilization, maintenance needs, and operator performance. The data is then analyzed and presented in easy-to-understand dashboards and reports, allowing warehouse managers to make data-driven decisions.

Forklift fleet management solutions offered by HCO Innovations are designed to help organizations optimize their forklift fleet performance. With their expertise in warehouse optimization, HCO Innovations provides innovative solutions that enhance safety, productivity, efficiency, and cost-effectiveness within warehouse operations.

Conclusion

Efficient management of the forklift fleet is crucial for achieving optimal performance, cost savings, and safety in warehouse operations. By monitoring and analyzing forklift fleet performance metrics, businesses can identify areas for improvement and implement strategies to enhance productivity, reduce costs, and ensure a safer working environment. Investing in advanced fleet management systems, such as those offered by HCO Innovations, can provide valuable insights and enable businesses to make data-driven decisions for better overall warehouse performance.

What are forklift fleet performance metrics?

Forklift fleet performance metrics are a set of measurable indicators that track the efficiency, productivity, and overall performance of a forklift fleet. These metrics help analyze various aspects such as fuel consumption, maintenance costs, downtime, productivity, and operator efficiency.

Why are forklift fleet performance metrics important?

Forklift fleet performance metrics play a crucial role in identifying areas of improvement and cost-saving opportunities within a forklift fleet. By analyzing these metrics, businesses can optimize their fleet operations, reduce expenses, enhance productivity, and ensure maximum uptime.

Which performance metrics should I track for my forklift fleet?

The choice of performance metrics to track for a forklift fleet depends on your specific goals and challenges. However, some commonly tracked metrics include fuel consumption per hour or per load, maintenance costs per forklift, average daily or weekly usage hours, percentage of planned vs. unplanned downtime, operator productivity (in terms of pallets moved or loads lifted), and accident/incident rates.

How can forklift fleet performance metrics help reduce costs?

By tracking and analyzing forklift fleet performance metrics, businesses can identify inefficiencies, bottlenecks, and areas of improvement. For example, high fuel consumption per hour might indicate poor operator habits or equipment issues, which can be addressed to reduce fuel costs. Regular maintenance based on metrics can prevent breakdowns and expensive repairs. Improved productivity can lead to time and labor savings, while reduced accidents can minimize damage and insurance costs.

Are there any industry standards for forklift fleet performance metrics?

While there are no universal industry standards for forklift fleet performance metrics, there are recommended best practices and benchmarks established by industry associations and experts. These guidelines can provide a baseline for comparison and help businesses assess their fleet performance against industry standards.

How often should I review and analyze forklift fleet performance metrics?

It is recommended to review and analyze forklift fleet performance metrics on a regular basis. The frequency can vary depending on the size of your fleet and your operational needs, but quarterly or monthly reviews are common. Regular analysis allows you to quickly identify trends, issues, and opportunities, enabling proactive decision-making and continuous improvement.

Can forklift fleet performance metrics help with fleet maintenance planning?

Yes, forklift fleet performance metrics are a valuable tool for maintenance planning. By monitoring metrics like maintenance costs, repair frequency, and equipment downtime, businesses can create proactive maintenance schedules, identify recurring issues, forecast replacement needs, and optimize their maintenance budget.

Are there any software solutions available to track forklift fleet performance metrics?

Yes, there are various fleet management software solutions available that can provide comprehensive tracking and analysis of forklift fleet performance metrics. These software solutions can streamline data collection, automate report generation, and provide real-time insights into fleet performance, helping businesses make data-driven decisions more efficiently.

How can I get started with tracking forklift fleet performance metrics?

To get started with tracking forklift fleet performance metrics, you should first identify the metrics that align with your business goals and operational challenges. Implement a system for data collection and analysis, whether manually or using fleet management software. Regularly track and analyze the chosen metrics and use the insights gained to make informed decisions and drive continuous improvement within your forklift fleet.

The Importance of Forklift Maintenance in Efficiency and Productivity

In today's competitive business landscape, efficiency and productivity are key factors that can make or break a company's success. One area where businesses can significantly improve their operations is forklift fleet management. Forklifts are an essential part of warehouse operations, playing a crucial role in material handling and inventory control. Ensuring the proper maintenance of forklifts is essential to enhancing efficiency and productivity in the warehouse environment.

The Impact of Forklift Maintenance on Efficiency

A well-maintained forklift fleet can have a substantial impact on the overall efficiency of warehouse operations. When forklifts are properly maintained, they operate at their optimal performance levels, minimizing downtime and reducing the risk of breakdowns or accidents. This ensures that materials can be moved quickly and safely, leading to smoother workflow processes and enhanced productivity.

Regular maintenance of forklifts also helps to identify potential issues before they become major problems. Professional maintenance technicians can detect any signs of wear and tear, damaged parts, or malfunctioning components during routine inspections. By addressing these issues early on, companies can prevent unexpected breakdowns and costly repairs, saving both time and money.

Furthermore, a well-maintained forklift fleet contributes to a safer working environment. Properly functioning forklifts reduce the risk of accidents that can lead to injuries or damage to products or infrastructure. This not only protects the well-being of warehouse personnel but also minimizes disruptions to overall operations.

Benefits of Regular Forklift Maintenance

Regular maintenance of forklifts offers several benefits that directly impact efficiency and productivity within the warehouse. Some of these benefits include:

- Improved Lifespan: By following a proactive maintenance plan, companies can extend the lifespan of their forklifts. Well-maintained forklifts experience less wear and tear, ensuring they remain in service for a longer period. This eliminates the need for frequent replacements, saving costs in the long run.

- Optimal Performance: Regular maintenance ensures that forklifts are operating at their peak performance levels. This includes regular lubrication, checking fluid levels, and inspecting key components such as the brakes, tires, and hydraulics. When forklifts are operating optimally, they can handle heavier loads more efficiently, resulting in increased productivity.

- Reduced Downtime: Scheduled maintenance allows companies to plan for necessary maintenance activities, minimizing unplanned and costly downtime. By conducting inspections and servicing during less busy periods, companies can avoid disruptions to daily operations and keep the workflow running smoothly.

- Compliance with Safety Regulations: Regular maintenance ensures that forklifts meet the required safety standards set by regulatory authorities. This helps companies avoid penalties and lawsuits resulting from non-compliance, while also promoting a culture of safety in the workplace.

- Improved Fuel Efficiency: A well-maintained forklift consumes less fuel, leading to cost savings and reduced environmental impact. Regular maintenance includes checking and cleaning filters, inspecting the engine, and ensuring optimal fuel usage, resulting in improved fuel efficiency.

Choosing a Professional Forklift Fleet Management Partner

To maximize the benefits of forklift maintenance, it is recommended to partner with a professional forklift fleet management company like HCO Innovations. HCO Innovations specializes in warehouse optimization and forklift fleet management, providing comprehensive solutions to enhance efficiency and productivity in warehouse operations.

With their expert knowledge and experience, HCO Innovations offers services such as warehouse layout evaluation, safety assessments, and turnkey maintenance solutions. By leveraging advanced cost-tracking software and a collaborative approach, they help clients across various industries achieve significant cost reductions and operational efficiency.

HCO Innovations understands the importance of proper forklift maintenance in optimizing warehouse operations and reducing material handling costs. They provide tailored solutions that consistently deliver exceptional return on investment, making them a trusted partner for businesses aiming to improve efficiency and productivity within their warehouses.

In conclusion, proper forklift maintenance plays a vital role in enhancing efficiency and productivity within warehouses. Regular maintenance not only improves the lifespan and performance of forklifts but also ensures compliance with safety regulations and reduces downtime. By partnering with a professional forklift fleet management company like HCO Innovations, businesses can optimize their warehouse operations, achieve cost reductions, and improve overall productivity.

If you would like to learn more about how HCO Innovations can help optimize your warehouse operations, please visit their website for more information.