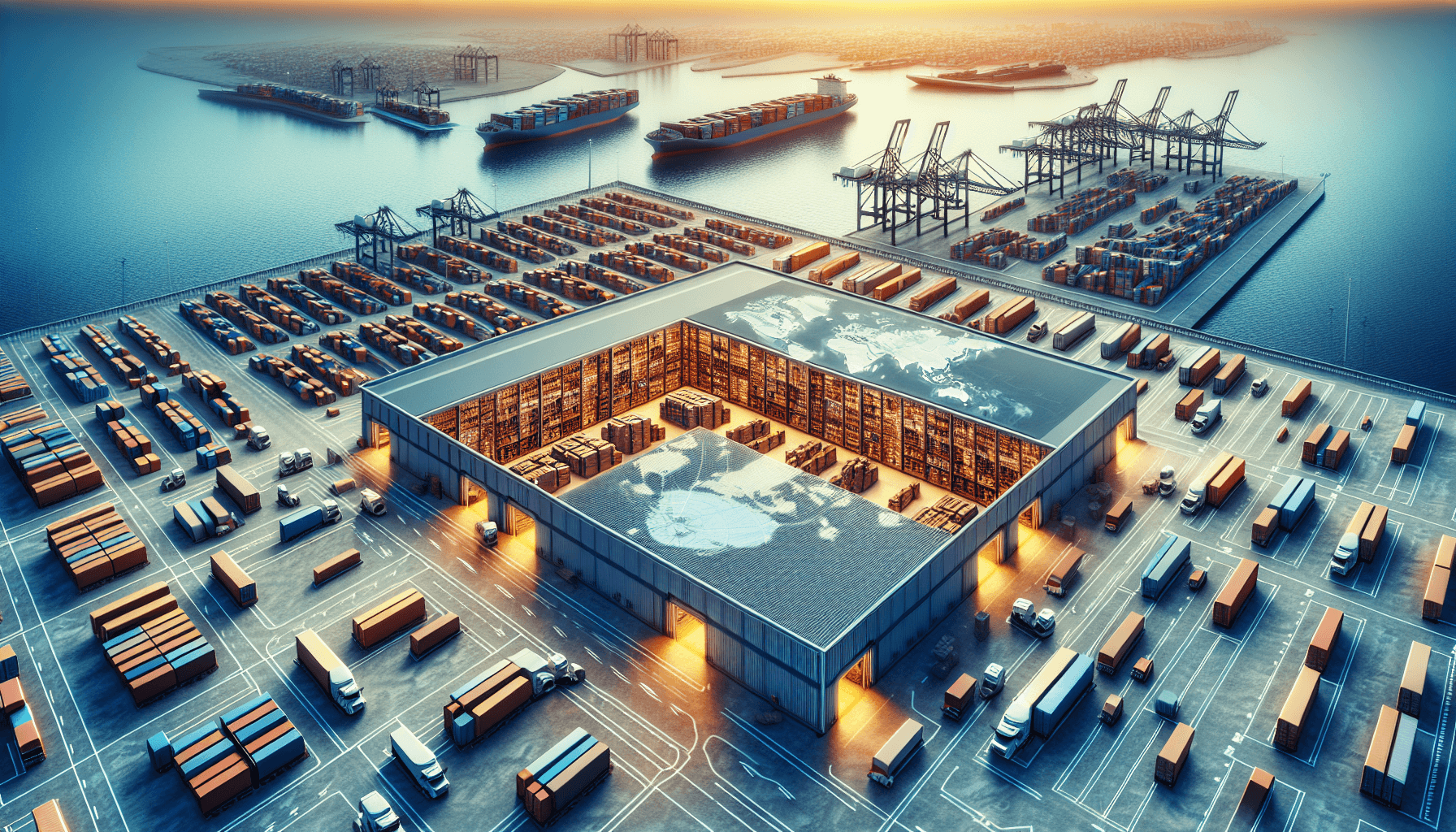

The global supply chain is a complex and ever-evolving network that connects manufacturers, suppliers, and distributors across the world. Over the years, the dynamics of the global supply chain have undergone significant changes, driven by factors such as technology advancements, changes in consumer demands, and economic shifts.

The Need for Warehouse Optimization

In this rapidly changing landscape, warehouse operations play a crucial role in ensuring smooth and efficient supply chain management. Warehouses act as the central hubs for storing and managing inventory, fulfilling orders, and coordinating the flow of goods. However, the evolving global supply chain landscape has put immense pressure on warehouses to adapt and optimize their operations to remain competitive in the market.

One of the key aspects of warehouse optimization is cost-effectiveness. Warehouse costs can have a significant impact on the overall profitability of a business. As the global supply chain continues to evolve, understanding the impact of these changes on warehouse costs becomes paramount for businesses seeking to streamline their operations and improve their bottom line.

The Impact of Global Supply Chain Changes on Warehouse Costs

Let’s take a closer look at the key ways in which global supply chain changes can impact warehouse costs:

- Increased Inventory Levels: As supply chains become more complex and global, businesses often need to maintain higher inventory levels to meet customer demands. While having a well-stocked warehouse is essential for customer satisfaction, it also comes with increased warehousing costs, including storage space, labor, and handling equipment.

- Inefficiencies in Transportation: Global supply chain changes can lead to longer lead times, increased transportation costs, and potential disruptions in the flow of goods. These inefficiencies can result in delayed deliveries, increased storage requirements in warehouses, and ultimately, higher costs for businesses.

- Changes in Packaging and Handling: As businesses adapt to changing consumer preferences and environmental regulations, there may be a need for modifications in packaging and handling practices. This can involve additional costs for procuring eco-friendly packaging materials, implementing new handling equipment, and training warehouse personnel.

- Increased Competition: Global supply chain changes often lead to increased competition as businesses expand their reach to new markets. To stay ahead in the market, warehouses may need to invest in advanced technology and automation systems, which can be costly but essential for improving efficiency and reducing operational expenses.

The Role of Warehouse Optimization Solutions

Given the impact of global supply chain changes on warehouse costs, it is imperative for businesses to adopt effective warehouse optimization solutions. These solutions can help businesses enhance safety, productivity, efficiency, and cost-effectiveness within their warehouse operations.

Warehouse optimization solutions offer a range of benefits, including:

- Improved Inventory Management: By leveraging advanced technologies such as warehouse management systems (WMS), businesses can gain real-time visibility and control over their inventory, enabling better planning, forecasting, and reducing the risk of overstocking or stockouts.

- Enhanced Labor Efficiency: Warehouse optimization solutions provide tools for streamlining labor-intensive tasks, such as picking and packing. Automation technologies, such as robotic picking systems and conveyor systems, can significantly improve productivity and reduce labor costs.

- Optimized Warehouse Layout: Through data analytics and simulation tools, businesses can optimize their warehouse layout to minimize travel time, reduce congestion, and improve overall operational efficiency. This can help save on labor costs and improve order fulfillment speed.

- Smart Integration with Transportation: Warehouse optimization solutions can integrate seamlessly with transportation management systems (TMS) to ensure smooth coordination between the warehouse and transportation activities. This integration helps reduce transportation costs, minimize delays, and streamline the flow of goods.

In conclusion, the evolving global supply chain landscape has a profound impact on warehouse costs. Understanding and adapting to these changes are crucial for businesses to remain competitive and profitable. By leveraging warehouse optimization solutions, businesses can optimize their warehouse operations, reduce costs, and improve overall supply chain efficiency. To learn more about how HCO Innovations can help optimize your warehouse operations and reduce costs, feel free to check out our Warehouse Cost Analysis services.