When it comes to warehouse operations, one crucial factor that significantly impacts order fulfillment is material flow. The way materials and products move through a warehouse not only affects efficiency but also plays a vital role in optimizing safety, productivity, and ultimately, cost-effectiveness. In this article, we will explore the impact of material flow on order fulfillment and how warehouse optimization solutions from HCO Innovations can make a difference.

The Importance of Efficient Material Flow

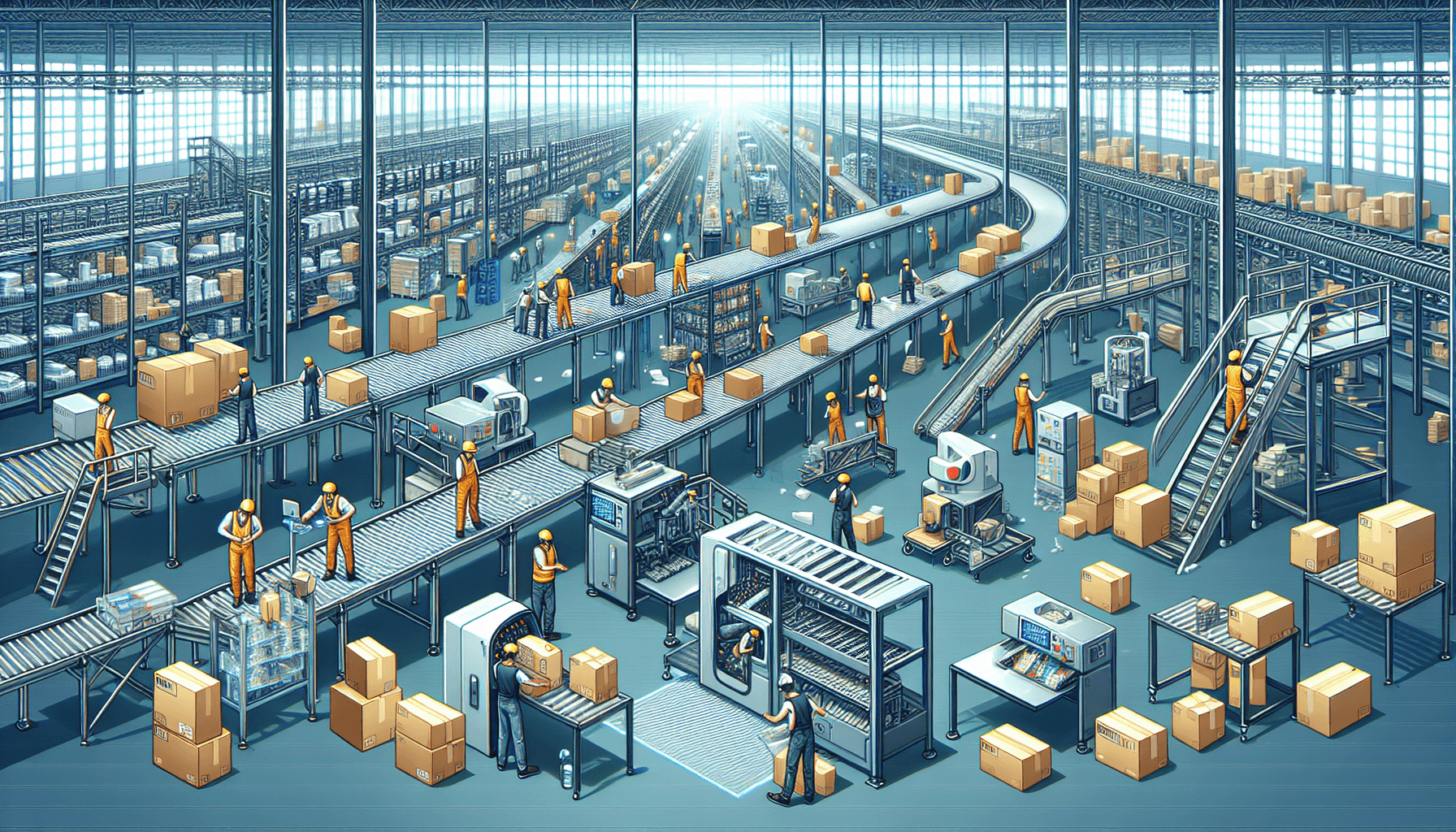

Efficient material flow is essential for maintaining smooth operations within a warehouse. When materials are organized and flow seamlessly from receiving to storage and then to order picking and shipping, it allows for faster and more accurate order fulfillment. This translates to improved customer satisfaction, reduced lead times, and increased profitability for businesses.

On the other hand, poor material flow can lead to various problems within a warehouse. Bottlenecks and congestion can slow down operations, resulting in delayed order fulfillment and decreased productivity. Inefficient material flow can also create safety hazards, making it important to address these issues and optimize the flow of materials within the warehouse.

The Impact of Material Flow on Safety

Efficient material flow is closely tied to safety within a warehouse. A well-organized layout and streamlined flow can minimize the risk of accidents and injuries. By optimizing material flow, businesses can ensure clear pathways, proper signage, and designated areas for equipment and pedestrians. This can eliminate potential hazards and create a safer working environment for warehouse personnel.

HCO Innovations specializes in warehouse optimization solutions that include material flow evaluation. By conducting a thorough analysis of your warehouse’s material flow, they can identify potential safety risks and provide recommendations for improvement. Whether it’s rearranging storage areas, implementing better signage, or optimizing workflow processes, HCO Innovations can help enhance safety and eliminate bottlenecks.

The Impact of Material Flow on Productivity

Efficient material flow directly impacts productivity within a warehouse. When materials are organized and readily accessible, it reduces the time and effort required for order picking and fulfillment. With optimized material flow, warehouse personnel can easily locate and retrieve items, reducing the likelihood of errors and improving overall productivity.

In addition, efficient material flow allows for better utilization of equipment and resources. By minimizing unnecessary movement and avoiding congestion, it increases the throughput of goods, enabling faster order fulfillment. This improved productivity not only benefits the warehouse but also positively impacts the entire supply chain, ensuring timely delivery to customers.

The Impact of Material Flow on Cost-Effectiveness

Efficient material flow has a direct correlation with cost-effectiveness within warehouse operations. By improving the flow of materials, businesses can reduce the time and resources required to fulfill orders. This can lead to lower labor costs, reduced equipment wear and tear, and minimized inventory holding costs.

HCO Innovations understands the importance of cost-effectiveness in warehouse operations. Their warehouse optimization solutions are designed to maximize efficiency while keeping costs in check. Through their expertise in material flow evaluation, they can identify opportunities for process improvements that not only enhance order fulfillment but also contribute to overall cost savings.

If you want to optimize material flow within your warehouse and improve order fulfillment, HCO Innovations can provide the expertise you need. Their team of professionals will evaluate your current material flow, identify areas for improvement, and implement solutions to enhance safety, productivity, efficiency, and cost-effectiveness.

Conclusion

Efficient material flow is crucial for successful order fulfillment within a warehouse. It impacts safety, productivity, and cost-effectiveness. By optimizing material flow, businesses can enhance efficiency, improve customer satisfaction, and ultimately, achieve a competitive edge in the market. With the warehouse optimization solutions offered by HCO Innovations, businesses can transform their warehouse operations and reap the benefits of streamlined material flow.

What is material flow?

Material flow refers to the movement of physical goods through a system, from the initial suppliers to the final customers. It involves the coordination and optimization of various processes such as sourcing, production, transportation, and distribution.

Why is material flow important in order fulfillment?

Material flow plays a crucial role in order fulfillment as it directly affects the efficiency, accuracy, and speed of delivering customer orders. A well-managed material flow ensures smooth operations, minimizes delays, reduces errors, and ultimately enhances customer satisfaction.

What are some common challenges in material flow?

Some common challenges in material flow include inventory management issues, bottlenecks in production or distribution processes, inefficient transportation and logistics, lack of visibility and real-time tracking, and coordination problems between different stakeholders involved in the supply chain.

How does an optimized material flow impact order fulfillment?

An optimized material flow streamlines the order fulfillment process, allowing for faster order processing, reduced lead times, and improved on-time delivery. It helps minimize stockouts and excess inventory, enhances order accuracy, and enables better resource allocation, resulting in cost savings and increased customer satisfaction.

What are some strategies for improving material flow in order fulfillment?

Some strategies for improving material flow in order fulfillment include implementing lean principles, adopting automation technologies, integrating supply chain management systems, utilizing data analytics for demand forecasting and inventory planning, collaborating with suppliers and logistics partners, and continuously monitoring and optimizing processes.

How can poor material flow impact customer satisfaction?

Poor material flow can lead to delayed order processing, stockouts, incorrect shipments, and longer lead times, all of which can greatly impact customer satisfaction. It may result in dissatisfied customers, negative reviews, loss of business, and damage to the company's reputation. By contrast, efficient material flow enhances the overall order fulfillment experience and promotes customer loyalty.

What role does technology play in optimizing material flow?

Technology plays a vital role in optimizing material flow by enabling automation, real-time tracking, data analysis, and integration across the supply chain. Technologies such as warehouse management systems, RFID tracking, barcode scanning, transport management systems, and order management software can significantly enhance material flow efficiency and visibility.

The role of automation in optimizing material flow for efficient order fulfillment.

Efficient order fulfillment is a key priority for any warehouse or distribution center. It involves the smooth and timely movement of products from the moment an order is received until it reaches the customer's doorstep. To achieve optimal efficiency, it is essential to have a well-organized material flow within the warehouse. In this article, we will explore the role of automation in optimizing material flow for efficient order fulfillment.

Why is Material Flow Important?

Material flow refers to the movement of goods from one point to another within a warehouse or distribution center. It encompasses all the activities involved in the handling, storing, and transporting of products. An efficient material flow ensures that goods are easily accessible, properly organized, and quickly dispatched to fulfill customer orders.

An optimized material flow brings several benefits to warehouse operations:

- Increased productivity: When goods are stored strategically and can be easily located and retrieved, employees spend less time searching for products, reducing wasted time and increasing overall productivity.

- Improved accuracy: Proper material flow reduces the likelihood of errors, such as picking the wrong item or misplacing products. This leads to improved order accuracy and customer satisfaction.

- Enhanced safety: Well-organized material flow reduces the risk of accidents, such as collisions between forklifts or injuries caused by improper storage. This promotes a safer working environment for warehouse personnel.

- Optimized space utilization: Efficient material flow allows for better use of warehouse space. By utilizing vertical space and optimizing layout, warehouses can reduce wasted space and accommodate more inventory.

The Role of Automation

Automation plays a crucial role in optimizing material flow for efficient order fulfillment. It involves the use of advanced technologies, such as warehouse management systems (WMS), barcode scanners, conveyors, and automated guided vehicles (AGVs), to streamline processes and improve overall efficiency.

Let's explore some key areas where automation can make a significant impact:

1. Inventory Management

Automation technology enables real-time tracking of inventory, providing accurate and up-to-date information about stock levels. With automated inventory management systems, warehouse personnel can easily identify the location of products, monitor stock levels, and even set up automated replenishment processes. This ensures that the right products are available when needed and reduces the chances of stockouts or overstock situations.

2. Warehouse Layout Optimization

An efficient warehouse layout is essential for smooth material flow. Automation tools, such as computer-aided design (CAD) software, can simulate different layout scenarios to identify the most efficient arrangement of aisles, shelving, and storage areas. By optimizing the warehouse layout, automation can minimize travel distances, reduce congestion, and improve the overall flow of products from receiving to shipping areas.

3. Order Picking and Fulfillment

Automation technologies, such as voice-directed picking systems and pick-to-light systems, can significantly improve the speed and accuracy of order picking. These systems guide warehouse employees through the picking process, providing them with clear instructions and reducing the chances of errors. By automating order picking, warehouses can fulfill orders more quickly and accurately, leading to improved customer satisfaction.

4. Material Handling Equipment Integration

Automation allows for seamless integration between different types of material handling equipment, such as forklifts and conveyors. This integration enables products to flow smoothly from one process to another without unnecessary delays or bottlenecks. Automated guided vehicles (AGVs) can also be used to transport goods within the warehouse, reducing the need for manual labor and optimizing material flow.

Conclusion

An optimized material flow is essential for efficient order fulfillment in warehouses and distribution centers. Automation plays a vital role in achieving this optimization, improving productivity, accuracy, safety, and space utilization. By leveraging automation technologies, such as inventory management systems, warehouse layout optimization tools, order picking systems, and material handling equipment integration, warehouses can streamline their operations and deliver exceptional customer experiences.

If you are looking to optimize your warehouse operations and reduce material handling costs, turn to HCO Innovations. As a leading management consulting firm specializing in warehouse optimization and forklift fleet management, HCO Innovations offers comprehensive services tailored to your specific needs. With their advanced cost-tracking software and collaborative approach, they can help you achieve significant cost reductions and operational efficiency. Visit HCO Innovations to learn more about their services and how they can be your trusted partner in optimizing your warehouse operations.