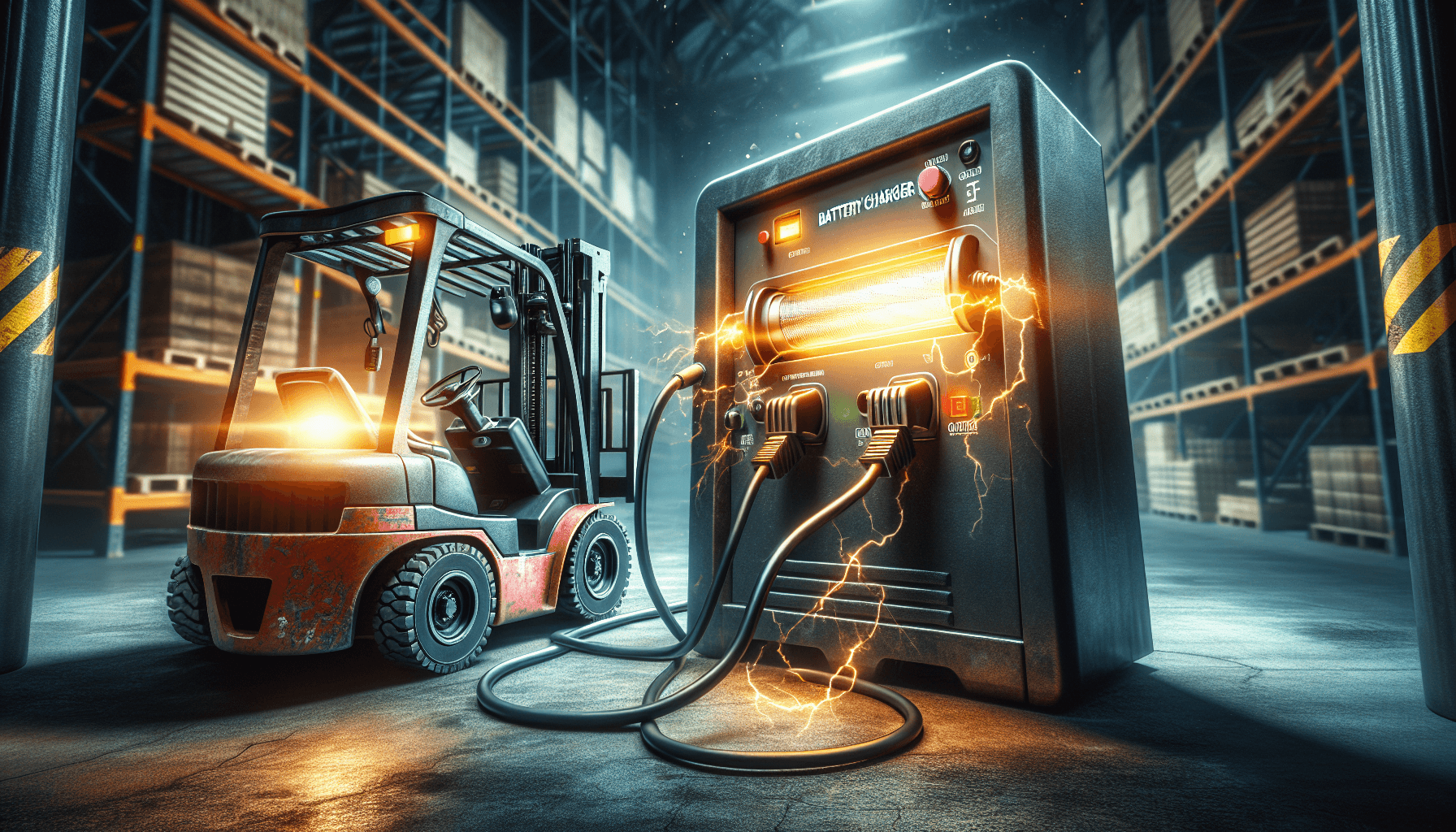

Did you know that overcharging can have a significant impact on the performance and lifespan of forklift batteries? In a warehouse environment, where forklifts are an essential tool for material handling and operations, it is crucial to understand the consequences of overcharging and how it can affect both safety and productivity.

The Dangers of Overcharging Forklift Batteries

Overcharging occurs when a forklift battery is left on charge for an extended period or is charged with a higher voltage than recommended. While it may seem like a harmless practice, overcharging can have several negative effects:

- Reduced Battery Life: Overcharging leads to excessive heat buildup in the battery, which can accelerate its deterioration. Batteries that are consistently overcharged may experience shortened lifespans, resulting in the need for more frequent replacements and increased costs for the warehouse.

- Increased Downtime: Overcharged batteries are more likely to suffer from thermal runaway, a phenomenon where the battery’s temperature rises rapidly, leading to a potential explosion or fire. To mitigate the risks, forklift operators may have to take the batteries out of service for inspection and cool-down periods, causing unnecessary downtime in warehouse operations.

- Decreased Performance: Overcharged batteries can also experience a drop in performance, resulting in reduced lift capacity, slower travel speeds, and shorter operating times. This can lead to decreased productivity in the warehouse and frustration for forklift operators who rely on efficient equipment to complete their tasks.

- Safety Hazards: Thermal runaway caused by overcharging can not only damage the battery but also pose significant safety hazards to workers and the warehouse facility. Fire hazards or toxic gas release can put both personnel and the entire operation at risk.

To prevent the negative consequences of overcharging, it is essential for warehouses to implement effective forklift fleet power management. HCO Innovations, a leader in warehouse optimization solutions, offers a comprehensive forklift fleet power management solution that focuses on maximizing battery performance and lifespan while ensuring safety and productivity.

How HCO Innovations Can Help

HCO Innovations understands the importance of maintaining an efficient and safe warehouse environment. With their warehouse optimization solutions, they can help businesses address the challenges related to forklift battery management:

- Advanced Charging Systems: HCO Innovations offers state-of-the-art battery charging systems that leverage smart technology to prevent overcharging. These systems monitor the battery’s voltage, temperature, and charge levels, ensuring that it is charged optimally without risking overcharging.

- Battery Monitoring and Maintenance: With HCO Innovations’ battery monitoring solutions, warehouses can track the health and performance of their forklift batteries in real-time. This proactive approach allows for early detection of potential issues and enables timely maintenance to extend battery life.

- Training and Best Practices: HCO Innovations provides comprehensive training programs and best practice guidelines for forklift operators and maintenance personnel. By educating the workforce on proper battery handling, charging, and maintenance techniques, warehouses can minimize the risks of overcharging and promote a culture of safety and efficiency.

By partnering with HCO Innovations for forklift fleet power management, warehouses can improve safety, productivity, efficiency, and cost-effectiveness within their operations. With their expertise, businesses can optimize battery usage and extend battery life, reducing the need for frequent replacements and ultimately saving on maintenance and replacement costs.

In conclusion, overcharging forklift batteries can have significant consequences for warehouse operations. From reduced battery life to increased downtime and safety hazards, the impacts of overcharging can be detrimental. To mitigate these risks and optimize forklift fleet power management, businesses can turn to HCO Innovations for their comprehensive solutions.

Implementing proper charging systems, monitoring battery health, and providing training on best practices are crucial steps toward ensuring the performance, safety, and longevity of forklift batteries. With HCO Innovations’ expertise and innovative solutions, warehouses can maximize their operational efficiency while minimizing costs and risks associated with overcharging.