Technology is constantly evolving and transforming various industries, and the field of material handling equipment is no exception. With the advent of new technologies, warehouse operations have become more efficient, productive, and cost-effective. In this article, we will explore the impact of technology on material handling equipment efficiency and how companies can benefit from embracing these advancements.

Automation and Robotics

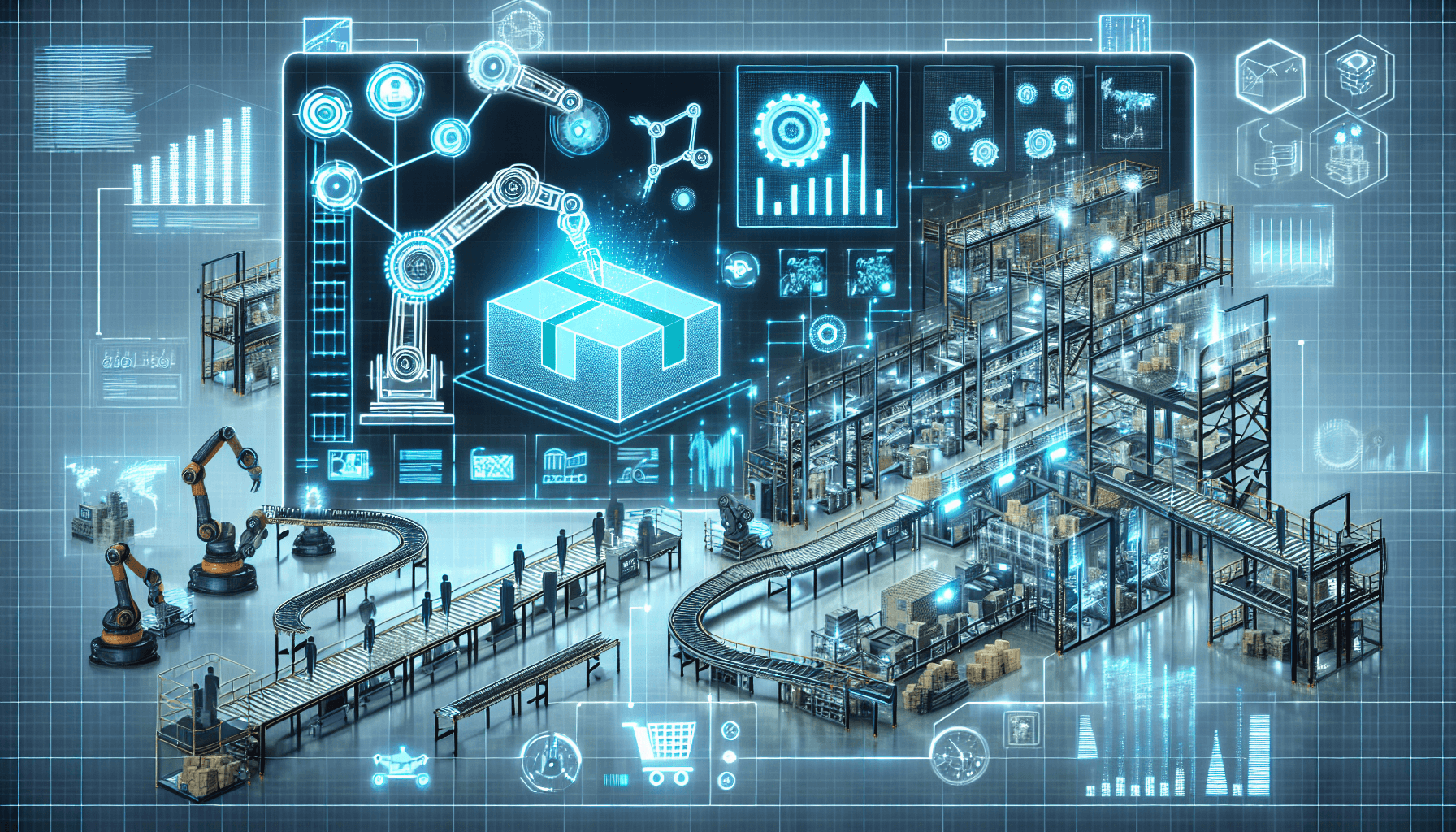

One of the key advancements in material handling equipment is the integration of automation and robotics. Automated systems such as conveyor belts, automated storage and retrieval systems (AS/RS), and robotic arms have significantly improved the speed and accuracy of material handling tasks. These technologies streamline the movement of goods within a warehouse, minimizing manual errors and reducing the risk of injuries.

The integration of robotics in material handling equipment has also brought about increased flexibility and scalability. Robots can be programmed to handle a wide range of tasks, from picking and packing to loading and unloading goods. Additionally, robots can work 24/7 without the need for breaks, resulting in improved productivity and throughput.

Software solutions have also played a crucial role in optimizing material handling equipment. Warehouse management systems (WMS) and warehouse control systems (WCS) allow for real-time tracking and monitoring of inventory, helping companies to effectively manage their stock levels and reduce the occurrence of stockouts. These software solutions also enable efficient inventory forecasting and replenishment, ensuring that the right products are available at the right time, reducing the risk of delays or shortages.

Data Analytics and Optimization

Another area where technology has made a significant impact on material handling equipment efficiency is data analytics and optimization. By collecting and analyzing data from various sources such as sensors, barcode scanners, and RFID tags, companies can gain valuable insights into their warehouse operations.

Real-time data analytics allows warehouse managers to identify bottlenecks, optimize workflows, and make informed decisions to improve overall efficiency. For example, by analyzing data on order picking time and storage utilization, managers can identify areas of improvement and implement strategies to reduce travel time, optimize pick paths, and maximize storage space.

Furthermore, predictive analytics can be used to anticipate maintenance requirements for material handling equipment. By monitoring equipment performance metrics, companies can schedule proactive maintenance tasks, minimizing downtime and reducing the risk of costly breakdowns. This ensures that equipment is always in optimal condition, leading to improved efficiency and productivity.

Training and Safety

Technology has also revolutionized training and safety in material handling equipment operations. Virtual reality (VR) and augmented reality (AR) technologies have emerged as valuable tools for training warehouse personnel in handling equipment safely and efficiently.

VR and AR simulations provide a realistic and immersive environment where employees can practice operating equipment without the risk of accidents or damage. These technologies allow for training in various scenarios, such as forklift operation, pallet stacking, or operating an AS/RS system. By training employees in a virtual environment, companies can ensure that they are competent and confident in their operations, leading to improved safety and reduced errors.

The integration of technology in material handling equipment has also introduced advanced safety features. Sensors, cameras, and proximity detection systems help prevent collisions and accidents by alerting operators to potential hazards. Automatic emergency braking systems, anti-slip surfaces, and ergonomic designs further enhance the safety of material handling equipment, reducing the risk of injuries and improving overall workplace safety.

In conclusion, the impact of technology on material handling equipment efficiency has been substantial. Automation and robotics have improved productivity and accuracy, while software solutions have enhanced inventory management and control. Data analytics and optimization enable companies to make informed decisions and optimize workflows. Training and safety have been revolutionized by VR, AR, and advanced safety features. Embracing these technological advancements can significantly benefit companies by improving safety, productivity, efficiency, and cost-effectiveness within their warehouse operations.

If you are interested in learning more about material handling equipment management, please visit HCO Innovations.

What is material handling equipment efficiency?

Material handling equipment efficiency refers to the ability of equipment used in warehouses, factories, and other industries to effectively move, transport, and store materials. It is a measure of how well the equipment performs its intended tasks while minimizing waste, reducing downtime, and maximizing productivity.

How does technology impact material handling equipment efficiency?

Technology plays a crucial role in improving material handling equipment efficiency. Advanced technologies such as automation, robotics, artificial intelligence, and IoT (Internet of Things) enable equipment to perform tasks more quickly, accurately, and with minimal human intervention. By incorporating technology, material handling equipment can streamline processes, optimize workflows, reduce errors, and enhance overall efficiency.

What are the benefits of using technology in material handling equipment?

Using technology in material handling equipment offers numerous benefits. Firstly, it improves operational efficiency by reducing manual labor, minimizing errors, and increasing throughput. Secondly, it enhances worker safety by automating hazardous tasks and creating safer working environments. Additionally, technology enables real-time data collection and analysis, allowing for better decision-making, predictive maintenance, and inventory management.

How can automation improve material handling equipment efficiency?

Automation can significantly improve material handling equipment efficiency by eliminating manual and repetitive tasks. By automating processes like picking, sorting, and packaging, equipment can perform these tasks faster, more accurately, and round the clock. Automation also reduces the risk of human errors, improves consistency, and enables seamless integration with other systems.

What role does robotics play in material handling equipment efficiency?

Robotics plays a crucial role in improving material handling equipment efficiency. Robots can perform complex tasks such as palletizing, order fulfillment, and inventory management with precision and speed. They can work continuously without fatiguing, ensuring consistent productivity. Additionally, robots equipped with sensors and AI capabilities can adapt and optimize their performance based on real-time conditions, further enhancing efficiency.

How does IoT contribute to material handling equipment efficiency?

The Internet of Things (IoT) contributes to material handling equipment efficiency by enabling connectivity and data exchange between different equipment, systems, and devices. IoT allows for real-time tracking, monitoring, and analysis of equipment performance, inventory status, and supply chain operations. By harnessing IoT capabilities, businesses can implement predictive maintenance strategies, optimize routes, and proactively address issues, leading to improved equipment efficiency.

Are there any downsides or challenges to implementing technology in material handling equipment?

While technology brings numerous benefits, there can be downsides and challenges to implementing it in material handling equipment. Initial costs and investment might be high, requiring careful consideration of the return on investment. Additionally, integrating and maintaining various technology systems can be complex, requiring expertise and resources. Cybersecurity and data privacy concerns also need to be addressed when relying on technology in equipment operations.

Can smaller businesses benefit from incorporating technology in material handling equipment?

Absolutely! While larger businesses might have more resources to invest in advanced technologies, smaller businesses can still benefit from incorporating technology in material handling equipment. There are various scalable and cost-effective solutions available that cater to the specific needs of smaller operations. Implementing technology can help smaller businesses improve operational efficiency, reduce costs, and compete effectively in the marketplace.

What are some future trends in technology for material handling equipment?

The future of technology for material handling equipment holds exciting possibilities. Some emerging trends include the use of artificial intelligence and machine learning algorithms to optimize warehouse layouts, the integration of virtual reality and augmented reality for training and remote support, and the adoption of drones for inventory management and surveillance. The continuous advancements in technology promise even greater efficiency, accuracy, and productivity in material handling equipment.

Automation in Warehouse Management Systems.

In today's fast-paced and highly competitive business landscape, efficiency and optimization have become paramount for companies across industries. This is especially true for warehouse management systems, where the ability to streamline operations and reduce costs can make a significant impact on the bottom line. One of the most effective ways to achieve this is through the implementation of automation technologies.

The Role of Automation in Warehouse Management Systems

Automation refers to the use of advanced technologies and systems to control and manage various aspects of warehouse operations. This includes tasks such as inventory management, order fulfillment, picking and packing, and even transportation and delivery. By automating these processes, companies can improve accuracy, reduce errors, and increase overall efficiency.

One major area where automation has revolutionized warehouse management systems is through the use of automated guided vehicles (AGVs) and robotics. These intelligent machines are designed to navigate the warehouse floor, pick and transport items, and even load and unload trucks with minimal human intervention. By eliminating the need for manual labor in these repetitive and time-consuming tasks, companies can achieve significant cost savings and operational efficiencies.

Another key aspect of automation in warehouse management systems is the use of advanced software and algorithms. These systems can analyze real-time data from various sources, such as inventory levels, order volumes, and customer demand, to optimize the allocation of resources and improve order fulfillment. By leveraging technologies like artificial intelligence and machine learning, companies can make smarter decisions and adapt to changing market conditions rapidly.

Additionally, automation in warehouse management systems extends to the use of cutting-edge technologies such as Internet of Things (IoT) devices and sensors. These devices can be placed throughout the warehouse to collect and transmit data on various parameters, such as temperature, humidity, and asset location. By having real-time visibility into these critical factors, companies can proactively address issues and ensure the smooth flow of operations.

The Benefits of Automation in Warehouse Management Systems

The implementation of automation in warehouse management systems can bring numerous benefits to businesses. Here are some key advantages:

- Improved Efficiency: Automation reduces the reliance on manual labor and increases operational speed and accuracy. This leads to faster order fulfillment, reduced cycle times, and improved overall efficiency.

- Cost Reduction: By eliminating errors, minimizing rework, and optimizing resource allocation, automation helps companies reduce labor costs, storage costs, and transportation costs.

- Enhanced Accuracy: Automated systems are less prone to errors compared to human-operated systems. This results in improved order accuracy, reduced returns, and enhanced customer satisfaction.

- Increased Scalability: Automation technologies can easily scale up or down to meet fluctuating demands, ensuring that warehouse operations can adapt to changes without disruptions.

- Better Inventory Management: With real-time data and advanced algorithms, automation enables companies to optimize inventory levels, minimize stockouts, and reduce carrying costs.

Overall, the integration of automation technologies in warehouse management systems offers significant advantages for businesses seeking to optimize their operations and drive cost savings.

HCO Innovations: Your Partner in Warehouse Optimization and Automation

When it comes to implementing automation in warehouse management systems, partnering with a trusted and experienced consulting firm is crucial for success. That's where HCO Innovations comes in.

HCO Innovations is a leading management consulting firm based in Raleigh, North Carolina, specializing in warehouse optimization and forklift fleet management. With over a decade of experience, HCO Innovations offers comprehensive services, including warehouse layout evaluation, safety assessments, and turnkey maintenance solutions.

One of HCO Innovations' key strengths is their ability to leverage advanced cost-tracking software and a collaborative "boots on the ground" approach to help clients across industries achieve significant cost reductions and operational efficiency. By combining their expertise with the latest automation technologies, HCO Innovations delivers tailored solutions that consistently deliver exceptional return on investment.

Whether you are in the distribution, manufacturing, or food processing industry, HCO Innovations can help you optimize your warehouse operations and reduce material handling costs. With their holistic approach, they can assist in implementing automation technologies that align with your specific needs and objectives, ensuring that your warehouse becomes a highly efficient and cost-effective asset.

Don't wait to unlock the benefits of automation in your warehouse management systems. Contact HCO Innovations today and take the first step towards enhancing your operational efficiency and driving tangible cost savings.